Abstract

The high-k dielectric TiO2/ZrO2 bilayer composite film was prepared on a Si substrate by radio frequency magnetron sputtering and post annealing in N2 at various temperatures in the range of 573 K to 973 K. Transmission electron microscopy observation revealed that the bilayer film fully mixed together and had good interfacial property at 773 K. Metal-oxide-semiconductor capacitors with high-k gate dielectric TiO2/ZrO2/p-Si were fabricated using Pt as the top gate electrode and as the bottom side electrode. The largest property permittivity of 46.1 and a very low leakage current density of 3.35 × 10-5 A/cm2 were achieved for the sample of TiO2/ZrO2/Si after annealing at 773 K.

Similar content being viewed by others

Introduction

High dielectric constant [high-k] materials have been researched for a few years in material science and have been applied firstly in Intel's 45 nm MOSFET in 2007. Nowadays, for the demand of the next generation devices for sub-22 nm technology nodes, expect that high-k materials such as HfO2, ZrO2, Ta2O5, and rare earth oxides are extensively researched, and binary oxides of high-k materials become more attractive and are expected to be utilized in the future ultra large scale integrated circuit [1–8]. Among them, ZrO2 has a relatively high permittivity, large band gap, and good thermal and chemical stabilities. TiO2 is a high-k material with a very high permittivity of about 80 [9]. In order to improve the permittivity of ZrO2, the feasible way is to fabricate ZrO2-TiO2 composite films. Meanwhile, as a composite thin film, the addition of TiO2 can improve the crystallization temperature [10, 11]. As ZrO2-TiO2 binary oxides, a nanolaminate structure which can tailor the electrical properties of dielectric stacks has many applications such as MIM diodes, storage capacitors, non-volatile memories, and transparent thin film transistors; thus, the nanolaminated ZrO2-TiO2 high dielectric constant thin film is worth studying

Concerning high-k stacks on silicon, the interface has an important role to influence the device. Normally, it is often thought that TiO2 is easier to react with the Si substrate which may deteriorate the property of the device, and thus, TiO2/ZrO2/Si stacks may have better electrical characterization [12–14]. In the present work, metal-oxide-semiconductor [MOS] capacitors with high-k gate dielectric TiO2/ZrO2/p-Si were fabricated using Pt as the top gate electrode and as the bottom side electrode. The structure and electrical property of the TiO2/ZrO2/Si stack are studied.

Experimental details

ZrO2 and TiO2 thin films were grown onto p-type (100) Si (P~1015 cm-3) to fabricate TiO2/ZrO2/Si stacks by radio frequency magnetron sputtering at room temperature. Pure ZrO2 (99.999%) and TiO2 (99.999%) ceramic targets (50 mm in diameter) were used as the sputtering targets. The sputtering power of ZrO2 and TiO2 are 60 W and 30 W, respectively. Pure argon (99.999%) with 30 cm3/min flow rate controlled by a mass flow controller was used as sputtering gas, and the base pressure of the vacuum chamber is about 3 × 10-5 Pa. Sputtering was carried out at a pressure of 0.3 Pa. As for the deposited TiO2/ZrO2/Si stacks, post annealing of 573 K, 773 K, and 973 K in N2 for 30 min was performed.

The structural characteristics of the films were investigated by X-ray diffraction [XRD] (Bruker D8, Bruker, Billerica, MA, USA) and transmission electron microscopy [TEM] (FEI Tecnai G20, FEI Co., Hillsboro, OR, USA). Film thickness was determined by an ex situ phase-modulated spectroscopic ellipsometry [SE] (Model Jobin Yvon, HORIBA Jobin Yvon Inc., Edison, NJ, USA) over the spectral range of 1.5 to 6.5 eV at an angle of incidence of 70°. For the purpose of exploring electrical properties, a Pt/TiO2/ZrO2/p-Si MOS capacitor was fabricated by sputtering a Pt top electrode with an area of 1.96 × 10-7 m2 through a shadow mask. The back side of the wafer was HF-cleaned, and the Pt thin film was deposited. The MOS capacitors were electrically characterized using a Radiant Precision Premier (Radiant Technologies Inc., Albuquerque, NM, USA) tester system to obtain current-voltage [I-V] curves. Capacitance-voltage [C-V] measurements were performed by a precision LCR meter (Agilent 4294A; Agilent Technologies Inc., Santa Clara, CA, USA).

Results and discussion

The chemical composition of the TiO2/ZrO2/Si film can be measured by XRF, and all samples have nearly the same atomic Ti content of 21%, which indicates that the annealing process did not change the composition. Concerning the Ti content in the TiO2-ZrO2 binary system, the optimal content of about 21% has been verified in our previous work [10].

Spectroscopic ellipsometry was employed to measure the film thickness. The Tauc-Lorentz model which is especially suitable for an amorphous material was adopted to characterize the dielectric function of the TiO2/ZrO2 bilayer composite film [15–17]. In order to get the best fitting of SE data, different models were built due to the structure change of the TiO2/ZrO2 bilayer composite film. For the as-deposited thin film, a double layer optical model was built on Si (100) substrate, i.e., ZrO2 layer (L1) and TiO2 layer (L2), while for the annealed one, only one layer of the ZrO2-TiO2 composite thin film was built. Lastly, we can obtain the thickness of the as-deposited thin film with a ZrO2 layer (L1) of 27.639 ± 0.521 nm and TiO2 layer (L2) of 10.077 ± 0.627 nm. For the sample annealed at 773 K, the total thickness is 28.149 ± 1.102 nm. This result indicates that annealing makes the film denser and decreases the thickness.

The detailed structure of the TiO2/ZrO2/Si film was studied by TEM. We take the as-deposited and 773 K annealed samples representatively for analysis. Figure 1a presents the micrograph of the as-deposited sample. It can be clearly seen that the structure includes the two layer stacks of TiO2 and ZrO2 films and that the interface layer is observed between the ZrO2 film and the Si substrate. The physical thickness of ZrO2 and TiO2 thin films was measured to be 26 and 13 nm, respectively, which is consistent with the SE measurement. Figure 1b shows the cross-sectional image of the 773 K annealed TiO2/ZrO2 thin film. Obviously, after 773 K annealing, the two-layer structure became one layer for the mixture of TiO2 and ZrO2. It is reported that the multilayer film often fully mixed at 773 K [18]. The thickness from TEM can be calculated to be 30 nm and agrees well with the fitting result from SE.

Figure 2 presents the high-resolution TEM images of the interface property of the TiO2/ZrO2/Si films. It is believed that the interface layers play an important role on the electrical properties, including the dielectric constant and the leakage currents. From Figure 2, it can be seen that there is no obvious difference for the as-deposited and 773 K annealed samples. Both interface have a thickness of about 1.1 nm. We consider it to be SiO2 appearing at the ZrO2/Si interface. The relatively thin interface layer of 1.1 nm can be regarded as a good interfacial property for the TiO2/ZrO2/Si film. TEM also shows that both films are either amorphous or amorphous-like structures with a little nanocrystalline part in the 773 K annealed samples. This result can be confirmed by XRD, where the as-deposited thin film and the annealed ones are amorphous (XRD not shown here).

Figure 3 shows the atomic force microscopy [AFM] images of the TiO2/ZrO2 thin films. One can clearly see that the surface morphology of the films depends on the annealing temperature. The RMS roughness of the as-deposited film and annealed ones was measured over a 2 × 2 μm2 scanning range, and the values are 1.430, 1.529, 0.625 and 0.826 nm, respectively. One can see that the surface roughness of the thin film decreases at higher annealing temperature. At 773 K annealing temperature, the film has the smallest surface roughness, which may be attributed to the full incorporation of the TiO2 and ZrO2 film, as shown in TEM.

C-V characteristics of the MOS capacitor consisting of Pt/TiO2/ZrO2/p-Si was measured at high frequency (1 MHz). Figure 4 shows the C-V curves for the ZrO2/TiO2 thin films. It can be seen that at 773 K annealed temperature, the saturated capacitance is the highest. According to the saturated capacitance, we can get the effective dielectric constant of the thin films. The dielectric constants of annealed composite thin films are much higher than those of the pure ZrO2 (about 20) [19], which indicate that TiO2 has been incorporated in the ZrO2 film and improved the overall k value. Meanwhile, the dielectric constants of the annealed samples are higher than the as-deposited one, which is only 16.6 and can be attributed to the series capacity of the two-layer structure [20]. At 773 K, the dielectric constant of the composite thin film is the highest and reaches the maximum of 46.1, while at 973 K, the dielectric constant decreases to be 36.9. It can be concluded that the dielectric constants are affected by the annealing temperature. Normally, for a composite thin film, the dielectric constant is mainly dependent on the component of the film and the microstructure including the crystalline property, interface, surface roughness, and various vacancies and defects in the film, etc. [21–24]. At 773 K, based on the above analyses, the multilayer film fully mixed, has good interfacial property, has the smallest surface roughness, and has an amorphous structure, which results in the highest dielectric constant. The relatively small k of 33.0 at 573 K may result from the multilayer film that was only partly mixed although the film is amorphous. At 973 K, the decrease of dielectric constant is possibly due to interfacial reaction at high annealing temperature. We also obtain the flat band voltage [Vfb] from the high frequency C-V curves. Vfb primarily depends on deficiencies in theTiO2/ZrO2 film and the interface traps at the interface. The smallest Vfb is -0.53 V for the 773 K annealed thin film, and for the as-deposited and 573 K and 973 K annealed samples, the values of Vfb are - 1.01, - 0.71, and - 0.62, respectively. It can be inferred from the Vfb that annealing can reduce the deficiencies or traps in the composite TiO2/ZrO2 thin film and that the annealing temperature of 773 K is the optimal temperature.

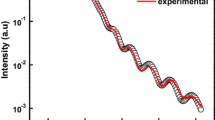

Figure 5 shows the density-voltage [J-V] characteristics of all the samples with gate electron injection (negative Vg). As shown in Figure 5, all the annealed samples have lower leakage current density than the as-deposited one for the reason that annealing makes the film denser and reduces defects in the film. For the 773 K annealed thin film, the leakage current density is about 3.35 × 10-5 A/cm2 at the applied voltage of -1 V, which is slightly higher than that of other high-k oxide materials. This may be caused by the interface layer as shown in Figure 2 and the defects in the film.

Conclusion

The high-k dielectric TiO2/ZrO2 bilayer composite film was prepared on a Si substrate by radio frequency magnetron sputtering and post annealing in N2 at various temperatures in the range of 573 K to 973 K. The bilayer film fully mixed together to become a composite single layer and has good interfacial property after annealing at 773 K. The largest property permittivity of 46.1 and a low leakage current density of 3.35 × 10-5A/cm2 were achieved for the sample of Pt/TiO2/ZrO2/Si/Pt after annealing at 773 K.

References

Choi C, Lee KL, Narayanan V: Impact of diffusionless anneal using dynamic surface anneal on the electrical properties of a high- k /metal gate stack in metal-oxide-semiconductor devices. Appl Phys Lett 2011, 98: 123506. 10.1063/1.3570655

Das T, Mahata C, Maiti CK, Miranda E, Sutradhar G, Bose PK: Effects of Ti incorporation on the interface properties and band alignment of HfTaOxthin films on sulfur passivated GaAs. Appl Phys Lett 2011, 98: 022901. 10.1063/1.3536520

Khomenkova L, Portier X, Marie P, Gourbilleau F: Hafnium silicate dielectrics fabricated by RF magnetron sputtering. J Non-Cryst Solids 2011, 357: 1860. 10.1016/j.jnoncrysol.2010.12.048

Martin D, Grube M, Reinig P, Oberbeck L, Heitmann J, Weber WM, Mikolajick T, Riechert H: Influence of composition and bottom electrode properties on the local conductivity of TiN/HfTiO2and TiN/Ru/HfTiO2stacks. Appl Phys Lett 2011, 98: 012901. 10.1063/1.3533802

Huang LY, Li AD, Zhang WQ, Li H, Xia YD, Wu D: Fabrication and characterization of La-doped HfO2 gate dielectrics by metal-organic chemical vapor deposition. Appl Surf Sci 2010, 256: 2496. 10.1016/j.apsusc.2009.10.094

Smith SW, McAuliffe KG, Conley JF: Atomic layer deposited Al2O3/Ta2O5nanolaminate capacitors. Solid-State Electronics 2010, 54: 1076. 10.1016/j.sse.2010.05.007

Lanza M, Iglesias V, Porti M, Nafria M, Aymerich X: Polycrystallization effects on the nanoscale electrical properties of high-k dielectrics. Nanoscale Res Lett 2011, 6: 108. 10.1186/1556-276X-6-108

Khomenkova L, Sahu BS, Slaoui A, Gourbilleau F: Hf-based high- k materials for Si nanocrystal floating gate memories. Nanoscale Res Lett 2011, 6: 172. 10.1186/1556-276X-6-172

Lee C, Ghosez P, Gonze X: Lattice dynamics and dielectric properties of incipient ferroelectric TiO2rutile. Phys Rev B 1994, 50: 13379. 10.1103/PhysRevB.50.13379

Ye C, Wang H, Zhang J, Ye Y, Wang Y, Wang BY, Jin YC: Composition dependence of band alignment and dielectric constant for Hf 1-x Ti x O2thin films on Si (100). J Appl Phys 2010, 107: 104103. 10.1063/1.3380588

Dong M, Wang H, Shen LP, Ye Y, Ye C, Wang Y, Zhang J, Jiang Y: Dielectric property and electrical conduction mechanism of ZrO2-TiO2 composite thin films. J Mater Sci: Mater Electr 2011. doi:10.1007/s10854–011–0378-x doi:10.1007/s10854-011-0378-x

Honda K, Sakai A, Sakashita M, Ikeda H, Zaima S, Yasuda Y: Pulsed laser deposition and analysis for structural and electrical properties of HfO2-TiO2composite films. Jpn J Appl Phys 2004, 43: 1571. 10.1143/JJAP.43.1571

Ramani K, Singh RK, Cracium V: Hf-O-N and HfO2barrier layers for Hf-Ti-O gate dielectric thin film. Microelectron Eng 2008, 85: 1758. 10.1016/j.mee.2008.05.001

Mikhelashvili V, Eisenstein G, Thangadurai P, Kaplan WD, Brener R, Saguy C: The use of nanolaminates to obtain structurally stable high- K films with superior electrical properties: HfNO-HfTiO. J Appl Phys 2008, 103: 114106. 10.1063/1.2936895

Cho YJ, Nguyen NV, Richter CA, Ehrstein JR, Lee BH, Lee JC: Spectroscopic ellipsometry characterization of high- k dielectric HfO2thin films and the high-temperature annealing effects on their optical properties. Appl Phys Lett 2002, 80: 1249. 10.1063/1.1448384

Nguyen NV, Richter CA, Cho YJ, Alers GB, Stirling LA: Effects of high-temperature annealing on the dielectric function of Ta2O5films observed by spectroscopic ellipsometry. Appl Phys Lett 2000, 77: 3012. 10.1063/1.1324730

Adachi S, Mori H: Optical properties of fully amorphous silicon. Phys Rev B 2000, 62: 10158. 10.1103/PhysRevB.62.10158

Kim HD, Roh Y, Lee JE, Kang HB, Yang CW, Lee NE: Characteristics of high- k gate dielectric formed by the oxidation of sputtered Hf/Zr/Hf thin films on the Si substrate. J Vac Sci Technol A 2004, 22(4):1342. 10.1116/1.1760751

Zhao X, Vanderbilt D: Structural and dielectric properties of amorphous ZrO2and HfO2. Phys Rev B 2006, 74: 12108.

Wong H, Iwai H: On the scaling issues and high-κ replacement of ultrathin gate dielectrics for nanoscale MOS transistors. Microelectron Eng 2006, 83: 1867. 10.1016/j.mee.2006.01.271

Kim T, Oh J, Park B, Hong KS: Correlation between strain and dielectric properties in ZrTiO4thin films. Appl Phys Lett 2000, 76: 3043. 10.1063/1.126573

Wang H, Wang Y, Feng J, Ye C, Wang BY, Wang HB, Li Q, Jiang Y, Huang AP, Xiao ZS: Structure and electrical properties of HfO2high- k films prepared by pulsed laser deposition on Si (100). Appl Phys A 2008, 93: 681. 10.1007/s00339-008-4695-8

Wang H, Wang Y, Zhang J, Ye C, Wang HB, Feng J, Wang BY, Li Q: Interface control and leakage current conduction mechanism in HfO2film prepared by pulsed laser deposition. Appl Phys Lett 2008, 93: 202904. 10.1063/1.3033526

Wang Y, Wang H, Zhang J, Wang HB, Ye C, Jiang Y, Wang Q: Improved thermal stability, interface, and electrical properties of HfO2films prepared by pulsed laser deposition using in situ ionized nitrogen. Appl Phys Lett 2009, 95: 032905. 10.1063/1.3184577

Acknowledgements

This work is supported in part by the National Nature Science Foundation of China (No. 51072049), STD and ED of Hubei Province (Grant Nos. 2009CDA035, 2008BAB010, 2010BFA016, and Z20091001).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors' contributions

MD carried out the electrical properties of TiO2/ZrO2 bilayer composite dielectrics and drafted the manuscript. HW conceived the study and participated in its design and coordination. CY participated in the revision of the manuscript. LPS and YW participated in the preparation of the TiO2/ZrO2 bilayer thin film. JQZ and YY contributed to the structure characterization of the TiO2/ZrO2 bilayer thin film. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Dong, M., Wang, H., Ye, C. et al. Structure and electrical properties of sputtered TiO2/ZrO2 bilayer composite dielectrics upon annealing in nitrogen. Nanoscale Res Lett 7, 31 (2012). https://doi.org/10.1186/1556-276X-7-31

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/1556-276X-7-31