Abstract

Development of nanostructured photocatalysts for harnessing solar energy in energy-efficient and environmentally benign way remains an important area of research. Pure and WO3-surface modified thin films of TiO2 were prepared by magnetron sputtering on indium tin oxide glass, and photoelectrochemical and photocatalytic activities of these films were studied. TiO2 particles were <50 nm, while deposited WO3 particles were <20 nm in size. An enhancement in the photocurrent was observed when the TiO2 surface was modified WO3 nanoparticles. Effect of potential, WO3 amount, and radiations of different wavelengths on the photoelectrochemical activity of TiO2 electrodes was investigated. Photocatalytic activity of TiO2 and WO3-modified TiO2 for the decolorization of methyl orange was tested.

WO3-surface modified TiO2 film showing better photocatalytic and photoelectrocatalytic activity.

Similar content being viewed by others

Background

Semiconductor-mediated photocatalytic process (advanced oxidation process (AOT)) has emerged as one of the most promising chemical oxidation processes, anticipated to play a crucial role in water treatment as standalone processes or in combination with conventional technologies [1-4]. It has now been well established that metal oxide-mediated photocatalysis is an attractive and promising technology to be applied in environmental clean up, clean energy production (H2 production from water splitting), self-cleaning surface, CO2 reduction under solar light or illuminated light source, and green synthetic organic chemistry (some selective photocatalytic oxidation reactions) [5-12]. The fundamentals of heterogeneous photocatalytic oxidation processes have been well documented in the literature [13-15]. Briefly, by shining light of energy equal to or greater than the band gap of semiconductor, an electron may be promoted from the valence band to the conduction band (e−cb) leaving behind an electron vacancy or ‘hole’ in the valence band (h+vb). If charge separation is maintained, the electron and hole may migrate to the catalyst surface where they participate in redox reactions with absorbed species. Specially, h+vb may react with surface-bound H2O or OH− to produce hydroxyl radical (OH•), and e−cb is picked up by oxygen to generate superoxide radical anion (O2 −•). These reactive species are primarily responsible for the photodegradation of organic pollutants. TiO2 is currently the best known and most widely used photocatalytic material because it is photostable, nontoxic, and relatively inexpensive [3,4]. One practical problem associated with semiconductors is the undesired electron/hole recombination process which in the absence of a proper electron acceptor or donor is extremely efficient and hence represents the major energy-wasting step, thus limiting the quantum yield (more than 90% charge carriers recombine). Several scientific strategies, such as doping with transition metal ions [16], deposition of noble metals [17], dye sensitization [18], and coupling with other low band gap semiconductors [19-21], have been put forward to prevent the electron-hole pair recombination in the semiconductor and improve the photocatalytic activity. Among the oxide semiconductors, coupling TiO2 with WO3 has been the subject of intensive investigations owing to a small band gap between 2.4 and 2.8 eV, a deeper valence band (+3.1 eV), effective absorption of the solar spectrum, unique physicochemical properties, and resilience to photocorrosion [22-25].

Semiconductor-based thin films are the subject of great interest not only for their excellent properties such as high chemical inertness, high thermal stability, and corrosion resistance but also for their excellent mechanical, optical, electrical, electronic, and catalytic properties. To the best of our knowledge, no attempt has been made to study the photoelectrochemical and photochemical property of WO3/TiO2 bilayers prepared by sputtering method. In the study presented here, we demonstrated the preparation of pure and WO3-surface modified TiO2 thin films using plasma-assisted sputtering method and studied their photoelectrochemical and photocatalytic properties.

Methods

Materials

Titanium (99.999%) and tungsten (99.99%) targets were obtained from Semiconductor Wafer, Inc. (Hsinchu, Taiwan), while indium tin oxide (ITO)-coated glass slide, sodium sulfate (>99.0%), and methyl orange (dye content ca 85%) were obtained from Sigma-Aldrich (St. Louis, MO, USA).

Preparation of thin films

Thin films were fabricated by automatic sputter coater (NSC-4000) onto ITO substrates using high-purity titanium and tungsten targets. Before sputtering, the substrates were cleaned for 15 min in methanol by ultrasonication. Furthermore, surfaces of titanium and tungsten targets were cleaned before each experiment by a pre-sputtering process for 1 min. The base pressure in the chamber was less than 2 × 10−6 torr, and the working pressure was set to 7 mtorr by adjusting the O2 gas flow at 70 sccm. The distance between the target and the substrate was fixed at 10 cm. The depositions of thin films were done at two different steps and conditions: TiO2 thin film was deposited first using 120 W for 40 min time deposition using radio frequency (rf) in pure oxygen. In the second step, WO3 flashed using a DC reactive sputtering with 70 W for 1, 2.5, 5, and 10 min on TiO2 thin film in high-purity oxygen environment. The substrate temperature was 300 K, while the sputtering rates of titanium and tungsten were 0.7 and 1.5 Å/s, respectively.

Characterization

Morphological characterization of the films was carried out by employing field emission scanning electron microscope (FESEM) while the elemental analysis was performed by energy-dispersive X-ray spectroscopy (EDS). Optical property was studied using a UV-vis spectrophotometer.

Evaluation of photoelectrochemical and photocatalytic activity

Photoelectrochemical behavior was studied using a three-electrode photoelectrochemical cell and a potentiostat. Saturated calomel electrode (SCE) and coiled platinum electrodes were used as a reference and counter electrodes, respectively. Irradiation of films was carried out under light with different wavelengths generated from 300-W xenon lamp. In all cases, the coated side (consisting of TiO2 or WO3/TiO2) of the films was irradiated. Different modules for UV and UV-vis along with cut off filters were used to get the radiations of desired wavelengths.

The photocatalytic tests were performed in a small photocell equipped with a quartz window and a magnetic stirring bar. For irradiation experiments, 100 mL of methyl orange solution with desired concentration was taken into the photocell and thin film slide was immersed into the dye solution. Irradiation was carried out using the abovementioned xenon light source. Samples (approximately 5 mL) were taken at regular time intervals from the cell, and concentration was determined by UV-visible spectrophotometer. Decomposition (decrease in absorption intensity vs. irradiation time) of the dye was monitored by measuring the change in absorbance.

Results and discussion

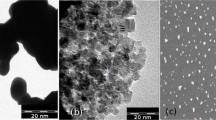

Structural analyses of films were carried out using FESEM, and representative images are illustrated in Figure 1. Pure titania film (Figure 1A) was found to be composed of nonspherical and irregular grains of <50-nm size with a certain degree of concavities between the grains. On the other hand, WO3 particles were somewhat spherical in shape and smaller in size (<20 nm) with homogeneous and narrow distribution throughout the surface of TiO2, as illustrated in Figure 1B. A representative EDS spectrum of film has been delineated in Figure 1C which indicated the presence of W, Ti, and O, along with Sn and In which are coming from ITO coatings. Unlabeled peaks may be ascribed to various elements present in glass slide.

FESEM images, EDS spectrum, and absorption spectra of TiO 2 and WO 3 /TiO 2 bilayer films. Field emission scanning electron microscopic image of (A) TiO2 film and (B) WO3/TiO2 bilayer film (deposition time = 5 min), (C) EDS spectrum of WO3/TiO2 bilayer film, and (D) absorption spectra of TiO2 and WO3/TiO2 films (deposition time = 5 min).

Figure 1D shows the UV-visible absorption spectra of pure TiO2 as well as TiO2 films modified with WO3. The spectra corresponded to a typical absorption behavior of TiO2, as obtained by other researchers as well. The absorption spectra of WO3-modified titania films were almost similar to that of bare titania, and surface modification by a low band gap semiconductor (WO3, approximately 2.8 eV) could not contribute in any notable visible band gap narrowing. The band gaps of bare TiO2 film and WO3/TiO2 film, prepared after 5 min, were calculated to be 3.3 and 3.2 eV, respectively.

Coated side consisting of TiO2 or WO3/TiO2 of the electrodes was illuminated with UV light radiation, and obtained potentiodynamic behavior is shown in Figure 2. It is obvious from the figure that the photocurrent was increased with increasing the applied voltage. Figure 2 also demonstrates the effect of the thickness of WO3, which was deposited on TiO2 surface and controlled by deposition time, on the potentiodynamic response of electrodes. Using thickness monitoring, the thickness of TiO2 film was calculated to approximately 170 nm, whereas the thickness of deposited WO3 layers was calculated to be about 10, 20, 45, and 90 nm for 1, 2.5, 5.0, and 10 min, respectively. It is interesting to note that the photocurrent density was found to increase with the increase in WO3 amount up to a critical amount, and a further increase failed to contribute positively on the overall photocurrent efficiency of the electrode. The overall effect of WO3 amounts on TiO2 surface was more significant at or higher than 0.6 V. This behavior may be explained in terms of interfacial electron transfer between WO3 and TiO2 as well as the extent of TiO2 surface coverage by WO3. In case of partial or optimum coverage of the TiO2 surface by WO3 particles, both oxide surfaces may absorb incident photons and generate charge carriers, which may undergo an interfacial charge transfer process thereby enhancing the overall flow of current. On the other hand, when the coverage of TiO2 surface by WO3 exceeds the critical limit or TiO2 surface is mostly covered by WO3, photons will largely be absorbed by WO3 ensuing lesser generation of electrons or photocurrents, noting the fact that WO3 is an intrinsically less active photocatalyst than TiO2.

Photocurrent action spectra or effect of wavelength on the photocurrent of pure and WO3-modified TiO2 electrodes (deposition time = 5 min) was measured at a constant applied anodic potential (0.9 V). Furthermore, three scans were performed at each wavelength and results together with error bars are presented in Figure 3. Since the linear relationship between light intensity and photocurrent can interfere with the effect of wavelengths and lead to an elusive conclusion, the intensity of incident light was kept constant, with the help of neutral density filters equipped with the xenon light source, at different wavelengths. Both the films showed maximum photocurrent at 320 nm and found to decrease continuously with the increase in wavelength (or decrease in photonic energy) up to 460 nm. However, the photocurrent of bare TiO2 was significantly less than that of WO3-modified TiO2 at any wavelength studied. By keeping in mind that the illumination of catalyst’s surface with high-energy photons may induce some changes by creating surface states [26], the direction of wavelength scanning was followed from higher to lower, i.e., from low-energy photons to high-energy photons in order to minimize any such kind of effect. The trend of photocurrent flow as a function of wavelengths agreed fairly well with absorption spectra of samples (Figure 3). Furthermore, since the specimens may show a certain degree of current drift over time scales of 5 to 10 min, ambiguity between photocurrents under illumination and dark current is created. Photocurrents (under illumination and dark current) were measured in a single experiment by turning the light on and off after every 25 s for more than 8 min at a constant applied voltage 0.9 V, and obtained results are presented in Figure 4. The photocurrent generated instantaneously upon illumination and reached a steady state while no current was observed under dark, even at high applied potential (0.9 V). It could be seen from the figure that both the electrodes possessed similar and reasonably good stability under studied experimental conditions and WO3-modified TiO2 electrode showed better photocurrent.

Since the photocatalytic property of mixed-oxide thin films is also of great significance, the activity of bare TiO2 and WO3-modified TiO2 was evaluated by studying the photooxidation of a dye, namely methyl orange, without applying any potential under ultraviolet radiation, and obtained results are illustrated in Figure 5. Thin film of TiO2 modified with WO3 (deposition time = 5 min) showed approximately 40% more activity for dye decolorization than that of pure TiO2. Photocatalytic experiments were also carried out under dark, without any applied potential and in the absence of photocatalyst, but no change in dye concentration was observed which indicates that the dye decolorization processes was truly photocatalytic.

In summary, a significant improvement in the aforementioned photoelectrochemical and photocatalytic processes of TiO2 was observed after surface modification with highly dispersed and very small size of WO3 nanoparticles. This effect could be attributed to the basic mechanism of photocatalysis. A significant amount of electrons and hole pairs could be generated upon illumination of catalyst’s surface with photons of appropriate energy. Unfortunately, most of the excited charge carriers (approximately 95%) go through the recombination process, in the absence of an effective electron transfer mechanism, which is a major energy-wasting process and overrides limitation of photocatalysts. When WO3 is effectively coupled with TiO2, the excited charge carriers undergo interfacial charge transfer phenomena and thus experience extended lifetime which in turn improved the photoelectrochemical and photocatalytic process. A plausible mechanism, based on the energy band diagram, showing the interfacial charge transfer between TiO2 and WO3 under UV light and applied anodic potential is presented in Figure 6A, together with schematic of WO3/TiO2/ITO layered structure (Figure 6B) [27].

Conclusions

The surface of TiO2 could be effectively functionalized by depositing nanoparticulates of WO3 by magnetron sputtering method. Microscopic analyses showed that TiO2 nanoparticles were nonspherical, irregular in shape, and <50 nm in size while WO3 nanoparticles were well distributed throughout TiO2 surface and were smaller (<20 nm) in size as compared to TiO2. Improvement in photocurrent and photocatalytic activity of TiO2 thin film was observed, approximately 50% and approximately 40%, respectively, after surface modification with WO3 nanoparticles. Both the films, TiO2 and WO3/TiO2, showed the highest photocurrent under 320-nm radiation, which continuously decreased with decreasing photonic energy. This study has presented a representative example by investigating the photoelectrochemical and the photochemical behavior of WO3-modified TiO2 thin film; this simple and effective methodology could be applied to develop other mixed-metal oxides for solar energy conversion and environmental decontamination.

References

Likodimos V, Dionysiou DD, Falaras P. Clean water: water detoxification using innovative photocatalysts. Rev Environ Sci Biotechnol. 2010;9:87–94.

Woan K, Pyrgiotakis G, Sigmund W. Photocatalytic carbon-nanotube–TiO2 composites. Adv Mater. 2009;21:2233–9.

Zhao ZG, Miyauchi M. Nanoporous-walled tungsten oxide nanotubes as highly active visible-light-driven photocatalysts. Angew Chem Int Ed. 2008;47:7051–5.

Zou Z, Ye J, Sayama K, Arakawa H. Direct splitting of water under visible light irradiation with an oxide semiconductor photocatalyst. Nature. 2001;414:625–7.

Shanon MA, Bohn PW, Elimelech M, Georgiadis JG, Marinas BJ, Mayes AM. Science and technology for water purification in the coming decades. Nature. 2008;452:301–10.

Maeda K, Teramura K, Lu D, Takata T, Saito N, Inoue Y, et al. Photocatalyst releasing hydrogen from water. Nature. 2006;440:295–5.

Zhou H, Li X, Fan T, Osterloh FE, Ding J, Sabio EM, et al. Artificial inorganic leafs for efficient photochemical hydrogen production inspired by natural photosynthesis. Adv Mater. 2009;22:951–6.

Elvington M, Brown J, Arachchige SM, Brewer KJ. Photocatalytic hydrogen production from water employing a Ru, Rh, Ru molecular device for photoinitiated electron collection. J Am Chem Soc. 2007;129:10644–5.

Roy SC, Varghese OK, Paulose M, Grimes CA. Toward solar fuels: photocatalytic conversion of carbon dioxide to hydrocarbons. ACS Nano. 2010;4:1259–78.

Morris AJ, Meyer GJ, Fujita E. Molecular approaches to the photocatalytic reduction of carbon dioxide for solar fuels. Acc Chem Res. 2009;42:1983–4.

Varghese OK, Paulose M, LaTempa TJ, Grimes CA. High-rate solar photocatalytic conversion of CO2 and water vapor to hydrocarbon fuels. Nanoletters. 2009;9:731–7.

Rosenthal J, Luckett TD, Hodgkiss JM, Nocera DG. Photocatalytic oxidation of hydrocarbons by a bis-iron(III)-í-oxo pacman porphyrin using O2 and visible light. J Am Chem Soc. 2006;128:6546–7.

Turchi CS, Ollis DF. Photocatalytic degradation of organic water, contaminants: mechanisms involving hydroxyl radical attack. J Catal. 1990;122:178–92.

Mathews RW, MacEvoy SR. Photocatalytic degradation of phenol in the presence of near-UV illuminated titanium dioxide. J Photochem Photobiol A Chem. 1992;64:231–46.

Kamat PV. Meeting the clean energy demand: nanostructure architectures for solar energy conversion. J Phys Chem C. 2007;111:2834–60.

Anpo M. Use of visible light. Second-generation titanium oxide photocatalysts prepared by the application of an advanced metal ion-implantation method. Pure Appl Chem. 2000;72:1787–92.

Qamar M. Photodegradation of acridine orange catalyzed by nanostructured titanium dioxide modified with platinum and silver metals. Desalination. 2010;254:108–13.

Chatterjee D, Mahata A. Demineralization of organic pollutants on the dye modified TiO2 semiconductor particulate system using visible light. Appl Catal B Environ. 2001;33:119–25.

Liu L, Hensel J, Fitzmorris RC, Li Y, Zhang JZ. Preparation and photoelectrochemical properties of CdSe/TiO2 hybrid mesoporous structures. J Phys Chem Lett. 2010;1:155–60.

Qian S, Wang C, Liu W, Zhu Y, Yao W, Lu X. An enhanced CdS/TiO2 photocatalyst with high stability and activity: effect of mesoporous substrate and bifunctional linking molecule. J Mater Chem. 2011;21:4945–52.

Rawal SB, Bera S, Lee D, Jang D-J, Lee WI. Design of visible-light photocatalysts by coupling of narrow bandgap semiconductors and TiO2: effect of their relative energy band positions on the photocatalytic efficiency. Catal Sci Technol. 2013;3:1822–30.

Puddu V, Mokaya R, Puma G.L. Novel one step hydrothermal synthesis of TiO2/WO3 nanocomposites with enhanced photocatalytic activity. Chem Commun. 2007; 4749–51.

Song H, Jiang H, Liu X, Meng G. Efficient degradation of organic pollutant with WOx modified nano TiO2 under visible irradiation. J Photochem Photobiol A. 2006;181:421–8.

Su D, Wang J, Tang Y, Liu C, Liu L, Han X. Constructing WO3/TiO2 composite structure towards sufficient use of solar energy. Chem Commun. 2011;47:4231–3.

Paramasivam I, Nah Y-C, Das C, Shrestha NK, Schmuki P. WO3/TiO2 nanotubes with strongly enhanced photocatalytic activity. Chem Eur J. 2010;16:8993–7.

Roel VDK. Photoelectrochemical measurements. In: Roel VDK, Gratzel M, editors. Photoelectrochemical hydrogen production. New York: Springer, Electronic Materials: Science & Technology; 2012. p. 69–117.

Noh E, Noh K-J, Yun K-S, Kim B-R, Jeong H-J, Oh H-J, et al. Enhanced water splitting by Fe2O3-TiO2-FTO photoanode with modified energy band structure. Scientific World Journal. 2013;2013:1–8.

Acknowledgements

The authors would like to acknowledge the support provided by King Abdulaziz City for Science and Technology (KACST) through the Science and Technology Unit at King Fahd University of Petroleum and Minerals (KFUPM) for funding this work through project no. 10-NAN1387-04 as part of the National Science, Technology and Innovation Plan. The support of the Center of Excellence in Nanotechnology (CENT), King Fahd University of Petroleum and Minerals is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MQ (Qamar) was involved in the design, development of material and photoelectrochemical measurements, interpretation of results, and manuscript writing; QD prepared the thin films by sputtering; MIA measured the activity of the catalysts and helped in manuscript writing; MQ (Qamaruddin) performed the microscopic and the optical characterizations; and ZHY conceived of the study, participated in its design and coordination, and helped in drafting the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Qamar, M., Drmosh, Q., Ahmed, M.I. et al. Enhanced photoelectrochemical and photocatalytic activity of WO3-surface modified TiO2 thin film. Nanoscale Res Lett 10, 54 (2015). https://doi.org/10.1186/s11671-015-0745-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-0745-2