Abstract

The resistive switching characteristics of the Cu/SiO x /Pt structure (control sample) exhibited a direct correlation to humidity. The H2O vapor formed the Cu oxide at the Cu/SiO x interface, and Cu ions were injected from the Cu oxide into the SiO x layer, thus improving the resistive switching. However, the control sample demonstrated substantial switching dispersion in a vaporless environment. The Cu x O layer in the Cu/Cu x O/SiO x /Pt structure (Cu x O sample) helped the dissolution of Cu ions from the Cu electrode into the SiO x layer, enabling effective electrochemical resistive switching in a vaporless environment. The Cu x O sample exhibited low switching dispersion and favorable endurance characteristics in a vaporless environment.

Similar content being viewed by others

Background

Recently, resistive random access memory (RRAM) has attracted considerable interest because of its non-volatile resistance change in simple metal/insulator/metal structures [1, 2]. Depending on the material group [3], device structure [4, 5], and defect status [6, 7], various switching behaviors can be observed. The switching mechanisms are typically classified as either a valence change effect [8], a thermochemical effect [2, 9], or an electrochemical effect [10, 11], whereby distinct surface effects can be attributed to various mechanisms [12, 13]. Ke et al. proposed that the oxygen concentration influences the redox reaction in ZnO resistive switching [12], and Tsuruoka et al. suggested that H2O vapor plays as an essential role in the redox reaction of an electrochemical Cu/SiO2/Pt device [13, 14]. The effects of moisture on Cu/SiO2/Pt and Cu/Ta2O5/Pt devices were different due to different adsorption coefficients of water. H2O vapor formed a Cu oxide interface between the Cu electrode and the oxide layer after the forming process and also enhanced Cu migration within the oxide layer. The H2O vapor facilitates in the dissolution of Cu ions into the SiO2 layer, enabling effective resistive switching. The Cu/SiO2/Pt device does not perform the resistive switching without H2O vapor [13, 14]. However, there is no H2O vapor within a packaged chip, and this is a serious concern, because these devices are used in memory applications.

In this study, a Cu x O layer was inserted between the Cu and SiO x layer to improve the electrochemical resistive switching and minimize switching dispersion in a vaporless environment.

Methods

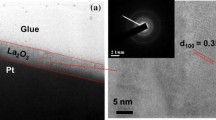

A 20-nm-thick SiO x layer was deposited on a Pt-coated substrate (Pt/Ti/SiO2/Si) using radio frequency sputtering at room temperature. Subsequently, a 200-nm-thick Cu electrode was deposited using a thermal evaporator at room temperature, to form the final Cu/SiO x /Pt structure (control sample). The device area was 5 × 10−5 cm2. To create the Cu/Cu x O/SiO x /Pt structure (Cu x O sample), an additional 1-nm Cu x O layer was deposited on the SiO x layer by using a thermal evaporator at room temperature. The structures of the control sample and the Cu x O sample are illustrated in Fig. 1, respectively. X-ray photoelectron spectroscopy (XPS; PHI-5000, ULVAC-PHI) was used to analyze the composition of the Cu x O layer. The electrical measurements were performed using an HP 4155B semiconductor parameter analyzer, and the measurements were taken in both air (60 % relative humidity) and N2 environments at room temperature. The bias voltage was applied on the top electrode while the bottom electrode was grounded.

Results and Discussion

Figure 2 depicts the XPS Cu 2p3/2 spectra of the Cu x O layer. The detailed chemical structure information was extracted through deconvolution of Cu 2p3/2 peaks, which showed a CuO peak locating at 934 eV and a Cu2O peak locating at 932.6 eV. The Cu x O layer is the mixture of CuO and Cu2O. Figure 3 shows the resistive switching characteristics of the control and the Cu x O samples in both air and N2 environments. A positive-forming voltage was used to initialize the resistive switching; the resistance state was then switched from an initial resistance state (IRS) to a low resistance state (LRS). Following this transition, a negative Reset voltage was applied to switch from the LRS to a high resistance state (HRS). Subsequently, using a positive Set voltage, the HRS was switched back to a LRS. The device resistance can be reversibly switched between a LRS and a HRS by a Set voltage and a Reset voltage. Figure 3c, d illustrates the resistive switching characteristics of the Cu x O sample in air and N2 environments, and the behaviors were similar to those of the control sample in air. According to our previous study [15], device structure, and switching behavior, the resistive switchings of the control sample in air and the Cu x O sample in both environments are dominated by the electrochemical model with a Cu conducting filament. However, as shown in Fig. 3b, the control sample in the N2 environment required substantially higher operating voltages. The control sample in the N2 environment also showed a reversible unipolar switching, and the temperature coefficient of LRS resistance was negative. Therefore, the switching mechanism should be the thermochemical effect with conducting filaments of oxygen-related defects.

Tsuruoka et al. proposed that a Cu/SiO2/Pt structure exhibits no resistive switching in a vacuum or N2 environment (no H2O vapor) because of the desorption of residual water from the SiO2 layer [13]. Because the composition of the SiO x film influences the switching mechanism [16], the result of this study in N2 differed from the result of Tsuruoka et al., which may be due to the dissimilar composition between SiO x and SiO2 layers. Although there was some difference between Tsuruoka’s study and our control sample in N2, these two samples both performed unfavorably because of a lack of humidity and exhibited no electrochemical resistive switching. Because no copper oxide was formed at the Cu/SiO x (or SiO2) interface of these two samples, no electrochemical resistive switching was observed. The Cu ion concentrations were calculated using the cyclic voltammetry (CV) method [17], and the results are presented in Fig. 4. The CV method is used to study the redox reaction of Cu within the device. The applied voltage swept to 0.15 V and then swept back until the current was zero. During this sweeping period, oxidized Cu ions were injected into the SiO x thin film. The amount of Cu ions (Q) can be calculated, and then, Cu ion concentration (C ion) can be determined by the formula \( {C}_{\mathrm{ion}}=\frac{Q}{q{N}_A}/V \), where N A is Avogadro’s number and V is the device volume. The Cu x O sample contained higher Cu ion concentrations than those in the control samples. In addition, the two samples contained larger Cu ion concentrations in air than in N2. Tsuruoka et al. proposed that H2O molecules would form a hydrogen-bond network at grain boundaries in SiO2 [13] and thus had larger Cu ion concentration. Therefore, the humidity and Cu x O layer both help the dissolution of Cu ions into SiO x layer. The electrochemical resistive switching has three rate-limiting processes [13]: the Cu ionization at the Cu/SiO x interface, the migration of Cu ions in the SiO x film, and the nucleation of Cu at the Pt bottom electrode. In this study, the Cu nucleation at Pt electrode would not the rate-limiting process. The control sample in N2 had the lowest Cu ion concentrations, and it cannot show an electrochemical resistive switching, which means that the Cu ionization at the Cu/SiO x interface is the rate-limiting process in N2. Willis and Lang [18] proposed the three possible mechanisms for the Cu ionization at the Cu/SiO2 interface under a positive applied voltage: the anodization-like process that Cu atoms are injected directly into the SiO2 layer by the dissolution reaction Cu → Cuz+ + ze −, Cu ions injected into the SiO2 from the Cu x O formed at the Cu/SiO2 interface due to reduction of the SiO2, and the chemical oxidation of Cu atoms at the Cu/SiO2 interface via H2O, O2, or out-gassing of the oxide [13]. In this study, the Cu/SiO x /Pt cannot electrochemically switch in N2. Therefore, the former two mechanisms should be excluded.

Figure 5a–c depicts the operating voltages of the two samples in both environments. The control sample in N2 exhibited the highest operating voltages because of the lowest Cu ion concentration within the SiO x layer. Both samples exhibited lower operating voltages in air, as the H2O vapor increased the Cu ion concentration in the SiO x layer. Tappertzhofen et al. proposed that there was no copper oxide at Cu/SiO2 interface before the forming process, but the copper oxide was found after the forming process in air [14]. In addition, this electrochemical oxidation was not observed in anhydrous atmosphere. We also fabricated a Ni (200 nm)/Cu x O (1 nm)/SiO x (20 nm)/Pt structure (not shown) which did not have an electrochemical resistive switching. This means that the 1-nm Cu x O interlayer did not provide enough Cu ions to form Cu conducting filaments. Since the Cu electrode cannot be directly ionized to be Cu ions and a 1-nm Cu x O interlayer does not provide enough Cu ions to form Cu conducting filaments, the possible explanation is that the Cu metal is transformed into immediate states of Cu oxide via the Cu x O layer and then Cu ions can be injected from these immediate states by a positive electric field. Since the copper oxide cannot be electrochemically formed without a moisture environment, a Cu x O layer in this study was deposited between the Cu and SiO x layers to solve this issue. The deposited Cu x O layer also can help the dissolution of Cu ions from the Cu electrode into the SiO x layer, thus increasing the Cu ion concentration in the SiO x layer. This increase in the Cu ion concentration effectively reduced the forming and Set voltages. Figure 5d–f shows the device resistances in both air and N2. The LRS conduction of the two samples in air and N2 exhibited ohmic behavior. The LRS resistances were approximately determined according to the current compliance during the Set process. The two samples exhibited lower LRS resistances in air, which may be due to an increased Cu ion concentration in the SiO x layer during the Set process [8]. This increased concentration of Cu ions caused a formation of wider conduction filaments. The IRS and HRS conductions of the two samples were dominated by the Schottky emission (not shown). The two samples exhibited lower IRS resistances in air because of a lower Schottky barrier height. All switching parameters of the Cu x O sample had larger variation in N2 than in air. H2O molecules would form a hydrogen-bond network at grain boundaries in SiO2 [13] and thus enhanced Cu migration in the SiO x layer. Therefore, the Cu x O sample had larger Cu ion concentration in air than in N2. The supply of Cu ions influenced the operating voltages and the stability to grow Cu conducting filaments. Hence, the Cu x O sample had a lower Cu ion concentration in N2 and thus had larger variation in switching parameters.

Figure 6 shows the endurance characteristics of the two samples in both environments. The control sample in N2 exhibited the least favorable endurance characteristics, because of its non-optimized thermochemical switching. Both of the samples exhibited a more favorable endurance in air than in N2, which indicated that H2O vapor increased the Cu ion concentration and thus improved the resistive switching. In a packaged chip, the RRAM device must switch in an environment without H2O vapor. The Cu x O sample demonstrated favorable endurance for more than 2000 cycles in the N2 environment, demonstrating that it is suitable for RRAM applications.

Conclusions

This study investigated the addition of a Cu x O layer to a Cu/SiO x /Pt structure for maintaining the electrochemical resistive switching capabilities in a vaporless environment. The Cu ionization at the Cu/SiO x interface is the rate-limiting process for the electrochemical resistive switching in N2. Therefore, Cu/SiO x /Pt cannot have an electrochemical resistive switching in N2. Therefore, in the Cu/Cu x O/SiO x /Pt structure, the Cu x O layer helped the dissolution of Cu ions from the Cu electrode into the SiO x layer, effectively minimizing the switching dispersion. The Cu/Cu x O/SiO x /Pt also exhibited favorable endurance characteristics in a vaporless environment, demonstrating that it is suitable for practical applications.

Abbreviations

- HRS:

-

high resistance state

- IRS:

-

initial resistance state

- LRS:

-

low resistance state

- RRAM:

-

resistive random access memory

- XPS:

-

X-ray photoelectron spectroscopy

References

Beck A, Bednorz JG, Gerber C, Rossel C, Widmer D. Reproducible switching effect in thin oxide films for memory applications. Appl Phys Lett. 2000;77:139–41.

Lee DY, Tsai TL, Tseng TY. Unipolar resistive switching behavior in Pt/HfO2/TiN device with inserting ZrO2 layer and its 1 diode-1 resistor characteristics. Appl Phys Lett. 2013;103:032905.

Pan F, Gao S, Chen C, Song C, Zeng F. Recent progress in resistive random access memories: materials, switching mechanisms, and performance. Mater Sci Eng R. 2014;83:1–59.

Tsai TM, Chang KC, Zhang R, Chang TC, Lou JC, Chen JH, et al. Performance and characteristics of double layer porous silicon oxide resistance random access memory. Appl Phys Lett. 2013;102:253509.

Huang CY, Jieng JH, Jang WY, Lin CH, Tseng TY. Improved resistive Switching characteristics by Al2O3 layers inclusion in HfO2-based RRAM devices. ECS Solid State Lett. 2013;2:63–P65.

Chang KC, Tsai TM, Zhang R, Chang TC, Chen KH, Chen JH, et al. Electrical conduction mechanism of Zn:SiOx resistance random access memory with supercritical CO2 fluid process. Appl Phys Lett. 2013;103:083509.

Lee CB, Kang BS, Benayad A, Lee MJ, Ahn SE, Kim KH, et al. Effects of metal electrodes on the resistive memory switching property of NiO thin films. Appl Phys Lett. 2008;93:042115.

Zhou P, Yin M, Wan HJ, Lu HB, Tang TA, Lin YY. Role of TaON interface for CuxO resistive switching memory based on a combined model. Appl Phys Lett. 2009;94:053510.

Russo U, Ielmini D, Cagli C, Lacaita AL. Self-accelerated thermal dissolution model for reset programming in unipolar resistive-switching memory (RRAM) devices. IEEE Trans Electron Devices. 2009;56:193–200.

Schindler C, Staikov G, Waser R. Electrode kinetics of Cu–SiO2-based resistive switching cells: overcoming the voltage-time dilemma of electrochemical metallization memories. Appl Phys Lett. 2009;94:072109.

Valov I, Waser R, Jameson J, Kozicki MN. Electrochemical metallization memories—fundamentals, applications, prospects. Nanotechnol. 2011;22:254003.

Ke JJ, Liu ZJ, Kang CF, Lin SJ, He JH. Surface effect on resistive switching behaviors of ZnO. Appl Phys Lett. 2011;99:192106.

Tsuruoka T, Terabe K, Hasegawa T, Valov I, Waser R, Aono M. Effects of moisture on the switching characteristics of oxide-based, gapless-type atomic switches. Adv Funct Mater. 2012;22:70–7.

Tappertzhofen S, Valov I, Tsuruoka T, Hasegawa T, Waser R, Aono M. Generic relevance of counter charges for cation-based nanoscale resistive switching memories. ACS Nano. 2013;7:6396–402.

Liu CY, Sung PW. Different resistive switching characteristics of a Cu/SiO2/Pt structure. Jpn J Appl Phys. 2011;50:091101.

Wang Y, Chen K, Qian X, Fang Z, Li W, Xu J. The x dependent two kinds of resistive switching behaviors in SiOx films with different x component. Appl Phys Lett. 2014;104:012112.

Tappertzhofen S, Mundelein H, Valov I, Waser R. Nanoionic transport and electrochemical reactions in resistively switching silicon dioxide. Nanoscale. 2014;4:3040–3.

Willis BG, Lang DV. Oxidation mechanism of ionic transport of copper in SiO2 dielectrics. Thin Solid Films. 2004;467:284–93.

Acknowledgements

The authors thank the National Science Council of R.O.C. for the financial supports under project No. NSC 102-2221-151-049 and the facility support from the National Nano Device Laboratories.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing Interests

The authors declare that they have no competing interests.

Authors’ Contributions

CYL designed the experiment, participated in the result analysis, and wrote the paper. ZYH prepared the devices and carried out the material analysis and electrical measurements. Both authors read and approved the final manuscript.

Authors’ Information

CYL is an associate professor in the Department of Electronic Engineering, National Kaohsiung University of Applied Sciences, Taiwan. ZYH is a master student in the Department of Electronic Engineering, National Kaohsiung University of Applied Sciences, Taiwan.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0), which permits use, duplication, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Liu, CY., Huang, ZY. Effects of a Cu x O Buffer Layer on a SiO x -Based Memory Device in a Vaporless Environment. Nanoscale Res Lett 10, 290 (2015). https://doi.org/10.1186/s11671-015-1003-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1003-3