Abstract

The one-step synthesis of oleic acid-coated TiO2 nanoparticles with visible light-driven photocatalytic activity was reported by this manuscript, using oleic acid-ethanol as crucial starting materials. The photocatalytic degradation of nitrogen monoxide (deNOx) in the gas phase was investigated in a continuous reactor using a series of TiO2 semiconductors, prepared from oleic acid- or acetic acid-ethanol solution. The surface modification on TiO2 by organic fatty acid, oleic acid, could reinvest TiO2 photocatalyst with the excellent visible light response. The deNOx ability is almost as high as 30 % destruction in the visible light region (λ > 510 nm) which is similar to the nitrogen-doped TiO2. Meanwhile, acetic acid, a monobasic acid, has a weaker ability on visible light modification of TiO2.

Similar content being viewed by others

Background

Visible light response modification has been one of the most important issues for photocatalysts, since TiO2 has large band gap energy of ca. 3.2 eV, which is active under irradiation of only UV light. Efforts to solve this problem have typically focused on many different modification strategies, although they often proceeded individually. One is focused on extending the range of excitation energies into the visible region by doping with elements to produce an excellent visible light responsive photocatalysts, such as N-doped TiO2, Cr-doped SrTiO3, and Ta- and N-codoped TiO2 [1–5]. Another one, the surface modification of a catalyst by dye sensitization or colorless organics, is also a good possibility to develop a method of designing a visible light responsive photocatalytic system. Dye-sensitized photocatalysis begins with the light absorption of dye and a subsequent electron transfer from the excited dye to the conduction band of the photocatalyst [6]. Various colorless organics acids, including ascorbic acid, salicylic acid, 5-sulfosalicylic acid, and so on have been used for the surface modification of TiO2. Attributed to the amount of surface hydroxyl groups introduced by these organic acids modification, the UV-vis wavelength response range of TiO2 photocatalyst was expanded and then modified TiO2 could be used as a visible light active photocatalyst [7–9]. In addition, such colorless organic acid surface-modified method was also designated as organic acid-coated method [7, 10]. Among various colorless organics surfactants, oleic acid is an excellent one because of its high affinity to the surface of superfine magnetite. The carboxyl groups from oleic acid could form ester-like linkages (C=O) or carboxylate linkages (C–O–O) with metal oxide, which played a positive role in the red-shift of the absorption edge of TiO2 or SrTiO3 nanoparticles [11, 12].

At the same time, the specific surface area, particle size, and crystal structure have a significant influence on photoefficiency. It is widely accepted that photocatalytic reactions mainly take place on the surfaces of photocatalysts [13]. The control of water generation speed, which plays an important role in the anhydrous solvothermal process, will result in samples with large specific surface area [14]. Acetic acid, which also possesses the carboxyl group, was used as one crucial starting material in such water-controlled release progress. However, the influences of acetic acid on the resulting products, the visible light activity mechanism, as well as the contribution of the work to the fields of visible light-driven photocatalysis were not reported or elaborated in detail. Oleic acid, an excellent surface modification agent, was expected to possess higher positive effect than acetic acid in such synthesis. The different effects of acetic acid and oleic acid on the carboxyl group-coated TiO2 particles prepared by solvothermal methods without water addition were studied.

Therefore, we expand on these aspects more explicitly in the current paper. There are two significant aspects of the work described in this paper. First, the synthesis of TiO2 particles in oleic acid-ethanol has been found to be successful. Hence, the absolute ethanol solution synthesis of TiO2 with nanosize should be an efficient progress that may inspire less aggregate material solvothermal synthesis. Second, photocatalysts with visible light activity has been intensively studied recently, but the use of oleic acid as a crucial starting material to design advanced photocatalysts with visible light activity in one-step reaction synthesis has been rarely reported. Hence, this work may be of interest to both photocatalysis scientists and those working in the area of visible light-driven photocatalyst design.

Methods

The surface modification on TiO2 nanoparticles by oleic acid was conducted through a solvothermal method with controlling the speed of water generation. The typical preparation route was as follows: 1.70 g tetrabutyl titanate was added into a mixed solution consisting of 45-ml dehydrated ethanol and 5-ml oleic acid, under stirring. The resulting transparent solution was then transferred into a Teflon-lined autoclave, with an internal volume of 100 ml, followed by solvothermal reaction in an electric oven at 200 °C for 4 h. After the reaction, the products were centrifuged, washed four times alternately with water and ethanol, then, finally dried under vacuum at 60 °C. “TOL” is used to describe this sample. In order to investigate the effect of the amounts of Ti source, the amount of tetrabutyl titanate was changed to 0.24 g, and the product was designated as TOS. In addition, acetic acid was also used instead of oleic acid. “TAL” represents the sample prepared from acetic acid-ethanol solution with a large amount of Ti source, and “TAS” represents the sample from the acetic acid-ethanol solution using a little amount of Ti source. For comparison, 0.04 g of P25 TiO2 powders were dispersed in the same volume of oleic acid or acetic acid-ethanol solution followed by transferring into the same stainless steel autoclave with a Teflon tube. The autoclave was heated and kept at the same 200 °C for 4 h, then, finally washed and vacuum dried. TiO2 was also synthesized by adding 1 ml of water into the same starting materials. Nitrogen-doped TiO2 [1] and pure commercial TiO2 (P25, Degussa) were also used for comparison.

The X-ray diffraction (XRD) patterns of the catalysts were measured from 10° to 80° 2θ using a Shimadzu XD-D1 X-ray diffractometer and graphite-monochromic CuKα radiation. The catalyst morphology was observed by using an FEI Tecnai G2 F30 transmission electron microscope (TEM) with a Gatan imaging filter (GIF) system. The diffuse reflectance spectra (DRS) were determined using powder samples (Shimadzu UV-2450). The vibration spectra were characterized by Fourier transform infrared spectroscopy (FTIR) (NEXUS 670, Nicolet). The specific surface areas were determined by the amount of nitrogen adsorptions at 77 K (Quantachrome NOVA 4200e) using the Brunauer-Emmett-Teller (BET) method.

Photocatalytic activity during the oxidative destruction of NO was determined by measuring the concentration of NO gas at the outlet of the reactor (373 cm3) during photoirradiation under a constant flow of 1 ppm NO-50 vol.% air (balanced N2) mixed gas (200 cm3 min−1) [15]. Since illumination area is the key point in the continuous gas phase photocatalytic reaction, all powder photocatalysts were laid flat on the same glass holder with a certain area. Approximately 0.04 g of powder catalyst was placed into a 20 × 15 × 0.5 mm glass holder, which was kept in the bottom center of the reactor. The mixed gas with a flowing velocity of 200 cm3/min continuously passed through the reactor. A 450-W high-pressure mercury arc lamp was used as the light source, where the light wavelength was controlled by selecting various filters, i.e., Pyrex glass for cutting off the light of wavelength <290 nm, Kenko L41 Super Pro (W) filter <400 nm, and Fuji triacetyl cellulose filter <510 nm [15]. According to a Japanese Industrial Standard (JIS), the deNOx characterization was carried out around room temperature. At the outlet of the reactor, the concentration of NO was determined using a NOx analyzer (Yanaco, ECL-88A) [16]. The characterization system used in the present research was similar to that of the Japanese Industrial Standard which was established at the beginning of 2004 [17]. It has been reported that in the present characterization system during the photocatalytic destruction, about 20 % of NO is directly reduced to N2, and the other 80 % is oxidized to NO3 − species [18]. For comparison, the photocatalytic activity of commercial titania powders (P25, Degussa) were also determined.

Results and discussion

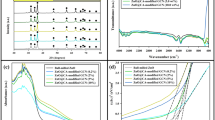

Figure 1 shows the XRD patterns of the powders prepared by the homogeneous precipitation-solvothermal treatment in (C4H9O)4Ti-oleic acid-ethanol solution or (C4H9O)4Ti-acetic acid-ethanol solution at 200 °C for 4 h. It can be seen that the sample consisted of single phase of anatase (JCPDS No. 021-1272) without remaining precursor. Besides anatase phase, P25 showed a characteristic peak at 27.4° attributed to rutile phase (JCPDS 065-0190), since P25 is a mixture of anatase and rutile. Certain Bragg peaks ({101} crystal facets) of as-prepared pure TiO2 samples showed a slight shift due to the formation of defects in the crystalline lattice of anatase. Those peaks observed for the samples from oleic acid-ethanol solution with a large amount of Ti source were broad due to the anisotropic growth of the nanoplates along the c-axis of the anatase lattice [19]. This indicates that the addition of acetic acid and oleic acid played different roles in the crystal structure formation.

Figure 2 shows the TEM photographs of the powders prepared in (C4H9O)4Ti-oleic acid-ethanol solution via solvothermal treatment at 200 °C. It can be seen from Fig. 2a, b, d that the TiO2 crystallite sizes were around 15 nm, while those shown in Fig. 2c was smaller than 10 nm. The mixed ethanol solvent had a smaller dielectric constant and could contribute to the decrease in solubility of titania during the crystallization process. As a result, the smaller particles were prepared. Meanwhile, owing to the chemical adsorption of oleic acid on the surface of TiO2, the crystal growth during the solvothermal treatment at 200 °C was greatly suppressed. The crystals prepared from the oleic acid-ethanol solution showed a smaller particle size (Fig. 2c, d) than those synthesized via the addition of acetic acid to ethanol solution. In addition, the effect of the adding amount of Ti source on particle size was limited, i.e., there was no significant distinction between two TiO2 nanoparticles via a large amount of Ti source or small one. Table 1 shows the BET specific surface areas (S.S.A.) of the powders prepared in various ethanol solutions with oleic acid or acetic acid addition. According to the results, the as-prepared TiO2 samples from absolute ethanol solution were nanoparticles with large specific surface areas. In addition, the powders obtained in oleic acid-ethanol solution with a large amount of Ti source possessed similar specific surface areas to those obtained in acetic acid addition one. TOS-TiO2 nanoparticles showed a larger specific surface area of 183.1 m2/g. It might be attributed to the inhibitory effect of oleic acid on crystal growth. The effect was more efficient when the small amount of Ti source was added.

The FTIR spectra of the samples synthesized from an oleic acid-ethanol solution or an acetic acid-ethanol solution after solvothermal reaction are shown in Fig. 3. For comparison, the FTIR spectra of the processed P25 TiO2 powder samples are also shown in Fig. 3c, d. These P25 TiO2 powder were dispersed in oleic acid or acetic acid-ethanol and heated in a sealed stainless steel autoclave at 200 °C for 4 h. FTIR analysis suggests the peaks around 1500 cm−1 corresponding to a carbon ingredient even P25 TiO2 powders washed and dried after being dispersed and heated in organic acid-ethanol solution. During treatment of all the TiO2 samples by the solvothermal reaction, their surfaces were readily covered with hydroxyl groups in an aqueous environment [12, 20] which was formed by slowly releasing water from ethanol [14]. Thus, the characteristic bands of hydroxyl groups, 1630 and 3406 cm−1, appeared in the FTIR spectra. Compared with other TiO2 powders, two new bands at 2858 and 2927 cm−1 appeared in FTIR spectrum of TiO2 nanoparticles synthesized by limited oleic acid (TOL, Fig. 3a). These two bands were attributed to the CH2 asymmetric and CH2 symmetric stretch, respectively [21]. It is worth noting that the intense peak at 1708 cm−1 assigned to the stretching vibration of C=O in oleic acid [22] was absent in the spectrum of TiO2 particles from oleic acid-ethanol solution. Instead, four new bands at 1383 and 1466 cm−1 appeared in the FTIR spectrum of TOL TiO2 while 1440 and 1520 cm−1 appeared in that of TAL TiO2, respectively. The band at 1383 and 1440 cm−1 could be assigned as the symmetric stretch of COO−, and the vibration bands at 1466 and 1520 cm−1 could be assigned as the asymmetric stretch of COO− [12, 20]. This suggests that the oleic acid was chemisorbed as carboxylate on the surface of TiO2. Based upon previous studies [23], the interaction between the carboxylate and metal atom is categorized into four types: monodentate, bridging bidentate, chelating bidentate, and ionic interaction. The wave number separation (Δ) between asymmetric and symmetric stretch IR bands can be used to analyze the type of interaction between the carboxyl and metal atom. The largest separation (200–320 cm−1) corresponds to the monodentate interaction, and the smallest one (<110 cm−1) is for the chelating bidentate. The medium range (140–190) is for the bridging bidentate. In the present work, Δ could be found as 80 and 83 cm−1. This indicates that there was one kind of interaction of carboxyl and metal on the surface of the sample, chelating bidentate (Δ = 80 or 83 cm−1).

Figure 4 shows the diffuse reflectance spectra of the TiO2 powders prepared by solvothermal treatment in (C4H9O)4Ti-oleic acid-ethanol solution or (C4H9O)4Ti-acetic acid-ethanol solution. The band gap energies were calculated using the Kubelka-Munk method based on the diffuse reflectance spectra, where F(R) = (1−R)2/2R [19]. It can be seen that all samples showed absorption edges around 400 nm due to the band gap absorption of anatase TiO2. Except TAS TiO2 with the band gap energy of 3.26 eV, the as-prepared anatase TiO2 nanoparticles possessed lower band gap energies, 2.97, 3.11, and 3.18 eV respectively, than pure anatase TiO2 which is ca. 3.2 eV. As expected, P25 showed the poor response in the visible light region due to its large band gap energy of ca. 3.28 eV. It is worthy noting that neither oleic acid nor acetic acid did not change the band structure of TiO2 while enhanced the visible light absorption by organic acid surface modification. The absorption of as-prepared TiO2 samples in the visible light range of 400–700 nm increased in the order:

TOS > TAL > TOL > TAS > P25

The visible light absorption of TiO2 particles prepared from organic acid-ethanol solution can be explained as follows: a dipole layer has been formed towards the inner TiO2 through the carboxyl group binding with the Ti4+. The carboxyl groups come from oleic or acetic acid, which is chemically adsorbed on the surface of TiO2 particles. This dipole layer induces an attracting potential for electrons instead of the TiO2 nanoparticles, which contributes to the absorption in the visible region. Similar phenomenon has also been reported by SrTiO3 bound by oleic acid and TiO2 bound by propionic acid and n-hexylamine on the surface showing a dipole layer formation [11, 12]. This dipole layer contributes to the reduction of the band gap of as-prepared anatase TiO2, leading to the red-shift of the absorption band edge.

To investigate the photocatalytic activity of the prepared samples, the oxidative photo destruction of NOx gas was performed as a model reaction. Figure 5 shows the photocatalytic deNOx ability of the TiO2 nanoparticles prepared by the homogeneous precipitation-solvothermal treatment in (C4H9O)4Ti-oleic acid-ethanol solution or (C4H9O)4Ti-acetic acid-ethanol solution at 200 °C for 4 h. For comparison, P25 was used as a standard sample. According to Fig. 5, the organic acid-modified TiO2 showed higher photocatalytic deNOx abilities than P25 TiO2 under not only UV light but also visible light irradiation. Oleic acid-coated titania (TOS) and acetic acid-coated titania (TAL) possessed visible light-induced activity under visible light irradiation with two different wavelengths (>510 or >400 nm). These results are consistent with the DRS spectra in that P25 TiO2 was able to absorb only UV light, while organic acid-coated TiO2 was able to absorb both UV and some degree of visible lights. It is notable that under irradiation in the visible light region (λ > 510 nm), the deNOx ability of P25 is modest, i.e., showing photodegradation of NOx less than 6 %. In contrast, the TiO2 nanoparticles from oleic acid (TOS) or acetic acid-ethanol solution (TAL) presented high photocatalytic activities. After 10 min irradiation, the NOx degradation efficiency reached 28.6 % for TOS TiO2 and 19.8 % for TAL TiO2, respectively. The dipole layer caused by the chemical adsorption of oleic or acetic acid results in the visible light response of organic acid-coated titania photocatalyst, and that from oleic acid was more competent. However, TiO2 samples prepared via the same solvothermal reaction but adding a different amount of Ti source (TOL and TAS) exhibited nearly the same activities as P25, as shown in Additional file 1: Figure S2. It suggests that there are some differences in the relationship between organic acid surface modification and the concentration of starting materials. In the present work, it is a good idea to combine low concentration of Ti source with oleic acid while high one with acetic acid. The relationship between organic acid surface modification (including fatty acid and monobasic acid) and the concentration of starting materials will be investigated and discussed in more details in future. In addition, nitrogen-doped TiO2 (N-TiO2) with the same anatase phase and specific surface area of 250.0 m2/g (Additional file 1: Figure S3) was used for comparison. As seen in Additional file 1: Figure S4, N-TiO2 nanoparticles possessed high visible light response due to the narrowed band gap of titania caused by the valence band of N2p band locating above O2p band [24]. Surprisingly, TOS presented photocatalytic activity as high as that of N-TiO2 under visible light irradiation with the wavelength of longer than 510 nm (Additional file 1: Figure S5). It is well known that photocatalytic activity is strongly dependent on physical properties such as the crystal phase, particle size, specific surface area, morphology, and so forth. In this work, considering that all samples possessed the similar crystal phase and specific surface area, the excellent photocatalytic activity of TOS prepared from oleic acid-ethanol solution with adding a little amount of (C4H9O)4Ti is mainly due to its stronger absorption of visible light, which creates more photo-induced electrons and holes. This is facilitated by the formation of a dipole layer on the surface of TiO2 [11, 12]. The dipole layer contributes to the absorption of visible light; therefore, this layer might become the trap center of the exciton, which could enhance the exciton binding energy more significantly [25]. It agreed well with the results in our previous work, which suggested the fatty acid played an important role in the visible light activity enhancement by surface modification [26]. According to the result that acetic acid is inferior to oleic acid in surface modification, acetic acid gave way to oleic acid in the absolute ethanol solution to prepare photocatalyst with high visible light activity. In a previous work, the photocatalyst showed stable activity for the repeated deNOx reaction for 120 min after the functional group of oleic acid chemically bonded on the surface [12].

Table 2 summarized the average light absorption degrees, photocatalytic deNOx abilities, and apparent quantum efficiencies (QEa) of different TiO2 samples under irradiation of high-pressure mercury arc (>510 nm). QEa was calculated according to Eq. (S1) (see Additional file 1) [2, 27]. It is clear that TOS nanoparticles possessed much higher QE a under visible light irradiation with the wavelength of longer than 510 nm, due to the higher ability of visible light absorption. This result indicates that TOS photocatalyst can utilize visible light with long wavelength more effectively than other TiO2 samples.

Finally, it is important to note that this organic acid-absolute ethanol solution synthesis applies to the situation that starting materials exhibit good solubility in such organic solvents only. For example, SrTiO3 crystals could not be prepared successfully from such ethanol solution by using SrCl2 as Sr source (as shown in Additional file 1: Figure S1).

Conclusions

In this work, we successfully prepared oleic acid-coated anatase TiO2 nanoparticles with high visible light activity from absolute ethanol solution. The functional group (−COO−) of oleic acid chemically bonded on the surface generated new absorption in the visible region and induced visible light responsive photocatalytic activity. In addition, acetic acid loses out to oleic acid in respect of visible light modification, although the dipole layer was formed in acetic acid-coated TiO2.

References

Yin S, Aita Y, Komatsu M, Wang J, Tang Q, Sato T (2005) Synthesis of excellent visible-light responsive TiO2-xNy photocatalyst by a homogeneous precipitation-solvothermal process. J Mater Chem 15:674–682

Yin S, Liu B, Zhang P, Morikawa T, Yamanaka K, Sato T (2008) Photocatalytic oxidation of NOx under visible LED light irradiation over nitrogen-doped titania particles with iron or platinum loading. J Phys Chem C 112:12425–12431

Li H, Yin S, Wang Y, Sekino T, Lee SW, Sato T (2013) Roles of Cr3+ doping and oxygen vacancies in SrTiO3 photocatalysts with high visible light activity for NO removal. J Catal 297:65–69

Sulaeman U, Yin S, Sato T (2011) Solvothermal synthesis and photocatalytic properties of chromium-doped SrTiO3. Appl Catal B-Environ 105:206–210

Li H, Yin S, Wang Y, Sato T (2013) Efficient persistent photocatalytic decomposition of nitrogen monoxide over a fluorescence-assisted CaAl2O4:(Eu, Nd)/(Ta, N)-codoped TiO2/Fe2O3. Appl Catal B-Environ 132–133:487–492

Chen F, Zou W, Qu W, Zhang J (2009) Photocatalytic performance of a visible light TiO2 photocatalyst prepared by a surface chemical modification process. Catal Commun 10:1510–1513

Li S, Liang W, Zheng F, Lin X, Cai J (2014) Ascorbic acid surface modified TiO2-thin layers as a fully integrated analysis system for visual simultaneous detection of organophosphorus pesticides. Nanoscale 6:14254–14261

Wang X, Zhao H, Quan X, Zhao Y, Chen S (2009) Visible light photoelectrocatalysis with salicylic acid-modified TiO2 nanotube array electrode for p-nitrophenol degradation. J Hazard Mater 166:547–552

Li S, Zheng F, Cai S, Liang W, Li Y (2013) A visible light assisted photocatalytic system for determination of chemical oxygen demand using 5-sulfosalicylic acid in situ surface modified titanium dioxide. Sensor Actuat B-Chem 188:280–285

Jafarpour M, Rezaeifard A, Ghahramaninezhad M, Feizpour F (2015) Dioxomolybdenum (VI) complex immobilized on ascorbic acid coated TiO2 nanoparticles catalyzed heterogeneous oxidation of olefins and sulfides. Green Chem 17:442–452

Nakayama N, Hayashi T (2008) Preparation of TiO2 nanoparticles surface-modified by both carboxylic acid and amine: Dispersibility and stabilization in organic solvents. Colloids Surf A Physicochem Eng Asp 317:543–550

Sulaeman U, Yin S, Sato T (2011) Visible light photocatalytic activity induced by the carboxyl group chemically bonded on the surface of SrTiO3. Appl Catal B: Environ 102:286–290

Xie M, Jing L, Zhou J, Lin J, Fu H (2010) Synthesis of nanocrystalline anatase TiO2 by one-pot two-phase separated hydrolysis-solvothermal processes and its high activity for photocatalytic degradation of rhodamine B. J Hazard Mater 176:139–145

Guo C, Wu X, Yan M, Dong Q, Yin S, Sato T, Liu S (2013) The visible-light driven photocatalytic destruction of NO x using mesoporous TiO2 spheres synthesized via a “water-controlled release process”. Nanoscale 5:8184–8191

Yin S, Hasegawa H, Maeda D, Ishitsuka M, Sato T (2004) Synthesis of visible-light-active nanosize rutile titania photocatalyst by low temperature dissolution–reprecipitation process. J Photochem Photobiol A Chem 163:1–8

Yin S, Ihara K, Aita Y, Komatsu M, Sato T (2006) Visible-light induced photocatalytic activity of TiO2−x A y (A = N, S) prepared by precipitation route. J Photochem Photobiol A 179:105–114

Japanese Industrial Standard (JIS) (2004) Fine ceramics (advanced ceramics, advanced technical ceramics)-Test method for air purification performance of photocatalytic materials-Part 1: Removal of nitric oxide. JIS R 1701-1: 1-9

Anpo M (2002) Recent development on visible light response type photocatalyst. NTS, Tokyo, p 9, ISBN -86043r-r009-03

Sofianou MV, Boukos N, Vaimakis T, Trapalis C (2014) Decoration of TiO2 anatase nanoplates with silver nanoparticles on the {1 0 1} crystal facets and their photocatalytic behaviour. Appl Catal B Environ 158–159:91–95

Yang K, Peng H, Wen Y, Li N (2010) Re-examination of characteristic FTIR spectrum of secondary layer in bilayer oleic acid-coated Fe3O4 nanoparticles. Appl Surf Sci 256:3093–3097

Kim YH, Lee DG, Cha HG, Kim CW, Kang YS (2007) Superlattice of Ag nanoparticles prepared by new one-step synthetic method in aqueous phase. Chem Mater 19:5049–5051

Limaye MV, Singh SB, Date SK, Kothari D, Reddy VR, Gupta A, Sathe V, Choudhary RJ, Kulkami SK (2009) High coercivity of oleic acid capped CoFe2O4 nanoparticles at room temperature. J Phys Chem B 113:9070–9076

Nakamoto K (1986) Infrared and raman spectra of inorganic and coordination compounds. Wiley, New York, p 20

Asahi R, Morikawa T, Ohwaki T, Aoki K, Tage Y (2001) Visible-light photocatalysis in nitrogen-doped titanium oxides. Science 293:269–271

Zou B, Xiao L, Li T (1991) Absorption redshift in TiO2 ultrafine particles with surfacial dipole layer. Appl Phys Lett 59:1826–1828

Li H, Yin S, Wang Y, Kobayashi M, Tezuka S, Kakihana M, Sato T (2013) Effect of carboxyl group on the visible-light photocatalytic activity of SrTiO3nanoparticles. Res Chem Interned 39:1615–1621

Li H, Yin S, Wang Y, Sato T (2012) Effect of phase structures of TiO2−x N y on the photocatalytic activity of CaAl2O4:(Eu, Nd)-coupled TiO2−x N y . J Catal 286:273–278

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51402139), Technology Foundation for Selected Overseas Chinese Scholar (Department of Human Resources and Social Security of Gansu Province), the basic scientific research business expenses of the Central University, and Open Project of Key Laboratory for Magnetism and Magnetic Materials of the Ministry of Education, Lanzhou University (No. LZUMMM2014008 and No. LZUMMM2015001).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

HL conceived of the study, carried out the acquisition, analysis, and interpretation of data, performed the sequence alignment, and drafted the manuscript. BL participated in the analysis of photocatalytic activity. SY helped to revise the manuscript. TS participated in the revising the manuscript critically for important intellectual content. YW helped to revise the manuscript. All authors read and approved the final manuscript.

Additional files

Additional file 1:

Supplementary information. Figure S1. XRD patterns of as-prepared samples by adding Sr source (SrCl2) into starting material (a) oleic acid-ethanol and (b) acetic acid-ethanol solutions with a large amount of Ti source. Figure S2. DeNOx abilities of different TiO2 samples. Figure S3. Crystalline morphology properties of nitrogen-doped TiO2 nanoparticles. Figure S4. DRS spectrum of nitrogen-doped TiO2 and P25 TiO2. Figure S5. DeNOx abilities of nitrogen-doped and TOS-TiO2 samples.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Li, H., Liu, B., Yin, S. et al. Visible Light-Driven Photocatalytic Activity of Oleic Acid-Coated TiO2 Nanoparticles Synthesized from Absolute Ethanol Solution. Nanoscale Res Lett 10, 415 (2015). https://doi.org/10.1186/s11671-015-1133-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1133-7