Abstract

The optoelectronic characteristics of molybdenum disulfide (MoS2)/ZnO flexible photodetectors are investigated. A red-shift effect and improved photocurrent properties of the flexible devices are demonstrated. MoS2 doping improved the photocurrent properties and conductivity. The photocurrent/dark current ratios of pure ZnO and MoS2/ZnO flexible photodetectors were 103 and 104, respectively. The responsivity of MoS2/ZnO increased, and the wavelength was red-shifted.

Similar content being viewed by others

Background

Molybdenum disulfide (MoS2) is a promising candidate for optoelectronic sensors because of its unique semiconducting channel when used as a phototransistor [1]. MoS2 phototransistors have recently been integrated with conventional semiconductor circuitry [2]. Bulk MoS2 is an indirect-gap semiconductor with a bandgap of 1.2 eV [3], whereas a single-layer MoS2 is a direct-gap semiconductor with a bandgap of 1.8 eV [4]. The photodetector (PD) has a broad spectral range, with photocurrent that monotonously increases as the wavelength of incident light is decreased from 680 to 400 nm. Two-dimensional and single-layer ultrasensitive MoS2 PDs have a photoresponsivity that is 106 better than that of the first graphene PDs (~0.5 mA W−1) [5]. In addition, a high-performance complementary inverter and selective gas sensing based on MoS2 field-effect transistors was studied [6–8].

There are various ways of synthesizing MoS2 nanostructures including electrochemical/chemical synthesis [9], laser ablation [10], solution-based exfoliation [11], and chemical vapor deposition (CVD) [12]. Another method, the rapid vibro-milling technique, was employed for investigating the potentiality of obtaining nano-sized powders. MoS2 nanoparticles obtained using vibro-milling, which can be applied at an industrial scale, have good solubility and biocompatibility. However, few applications of MoS2 synthesized by rapid vibro-milling have been reported. The rapid vibro-milling process was employed for investigating its potential for obtaining nanometer-sized powders [13]. The electro-optical properties of ZnO compounds have been studied extensively [14]. To our knowledge, MoS2/ZnO films have not been thoroughly investigated, which is the motivation for this research. The morphology and photoresponsivity properties of the MoS2 nanocrystals on ZnO film are studied and discussed.

Methods

Nanocrystalline MoS2 (from Alfa Aesar, 325 mesh, 99 %) was prepared using a high-energy ball-milling method. MoS2 was milled in ceramic milling vials (zirconia) using zirconia balls for 10, 20, and 40 h. The ball-to-powder weight ratio was 2:1 to produce at least 2 g of nanopowder. The mechanical milling was performed in a horizontal oscillatory mill (Retsch, PM 400) operating at 25 Hz. The as-synthesized materials were characterized by X-ray diffraction (XRD, Rigaku Dmax-33). The morphology and microstructure were examined using atomic force microscopy (AFM, Bruker) and transmission electron microscopy (TEM, Hitachi HF-2000).

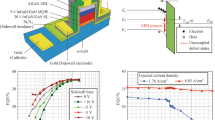

In this work, MoS2/ZnO was used to fabricate metal-semiconductor-metal (MSM) ultraviolet (UV) PDs, as shown in Fig. 1a. ZnO thin films were deposited on polyethylene naphthalate (PEN) substrates using radio frequency (RF) magnetron sputtering. During growth, the working pressure of the chamber was about 5 × 10−2 Torr, the RF power was 250 W, and the gas mixing ratio (Ar/O2) was 10:1. The thickness of the ZnO film was 100 nm. Ag/Ti electrodes were used to provide ohmic contact on the ZnO film. They were deposited using the electron beam evaporation method. The fingers of the Ag contact electrodes had a width of 20 μm, a length of 250 μm, and a space of 20 μm. In 10 cm3 of alcohol, 0, 0.1, and 0.2 g of MoS2 nanopowder were dissolved, respectively. The PD materials of MoS2 were spin-coated with a rotation speed of 300 RPM in the air. The photocurrent, dark current, and responsivity of the PDs were measured using an HP4156C semiconductor parameter analyzer. The spectral response of the PDs was measured with a light source which employed a 300-W xenon lamp as the light source and a monochromator covering the range of 300–700 nm.

Results and Discussion

Figure 1b shows an optical image of the flexible PDs with MoS2 coated on the ZnO/PEN substrate. The PDs exhibited a transmission of above 80 % and high bending strength. The bending curvature radius was larger than 10 mm. The Ag electrode pattern is shown in the inset of Fig. 1b. The interdigital electrodes have eight fingers with a fixed length of 2000 μm and a width of 50 μm. The spin-coated 5 wt% MoS2 nanocrystals on the ZnO/PEN substrate were also characterized using AFM to better understand the morphological properties with a large area of 100 × 100 μm, as shown in Fig. 1c. The pure ZnO film has a root-mean-square (rms) roughness of 13.2 nm, and the spin-coated MoS2 on the ZnO fim has that of 84.9 nm. In this study, the particle size of MoS2 was around 20~50 nm. During the spin-coating of MoS2, the nanocrystals had a uniform morphology and monodispersity. They were deposited on the ZnO/PEN substrate due to the gravitational force, causing the high roughness on the ZnO/PEN substrate.

MoS2 exhibits the characteristic peaks of a polycrystal structure in the XRD analysis, as shown in Fig. 2a. The XRD patterns also have a strong (002) peak, with a preferred orientation at 2θ = 10.47. No secondary phases were detected for the pure MoS2 samples. Nanocrystalline MoS2 was obtained using high-energy ball-milling. The full width at half maximum of the diffraction peak is rather small, which indicates that the film crystallinity is fairly good for the pristine MoS2 powder. The average grain size was determined by the line broadening of XRD patterns for various milling times. Many hours of milling were sufficient to produce nanocrystalline powders.

The average grain sizes were determined from XRD according to Scherrer’s equation [15]:

where D is the average grain size, k is a constant (equal to 0.89), λ is the X-ray wavelength (equal to 0.1542 nm), θ is the (002) peak angle, and β is half the peak width. The average grain size of powders milled for 20 h was 28.4 nm. The line broadening of the nanocrystalline samples is due to the small grain size and strain-induced response [16]. Figure 2b shows the XRD patterns of ZnO and ZnO films with 5 wt% MoS2 (~28 nm) coating layer. A (002) peak at 34.5° along with a strong (103) peak was observed for the ZnO thin films, indicating the polycrystalline nature of the thin films. The peak position of ZnO remains almost unchanged because the bottom ZnO layers were controlled to have a thickness of 100 nm. Therefore, the nanocrystalline MoS2 can be observed on the ZnO thin film by grazing incidence XRD.

Figure 3a shows a low-magnification TEM image. Spherical nanocrystals can be clearly observed. The diameter of the nanocrystals was about 20–50 nm. Figure 3b shows a high-resolution TEM image, indicating the periodic atom arrangement of the MoS2 nanosheets at a selected location. The interplanar distances of the crystal fringes are about 5.08 Å, corresponding to the spacing d-[100] of hexagonal MoS2 (JCPDS card no. 77-1716). A polycrystalline phase was present in the MoS2 matrix. The well-defined selected area electron diffraction (SAED) pattern clearly shows the diffraction spots in the inset of Fig. 3b. The energy-dispersive X-ray spectroscopy (EDS) line profiles indicate that the nanocrystal consists of Mo and S as shown in Fig. 3c. The signals were generated by the nanobeam incident to the nanocrystal MoS2.

Figure 4 shows the current-voltage (I-V) characteristics of the PDs with different MoS2 layers under dark and illumination conditions. The measurements were conducted at 5-V bias and 340-nm illumination. The results show that the light current of the photodetectors with MoS2 layers was enhanced. The highest photocurrent was obtained for the device with a 5 wt% MoS2 layer. The photocurrent to dark current contrast ratios of the 0, 1, and 5 wt% MoS2 PDs biased at 5 V were 8840, 13,100, and 17,800, respectively. MoS2 thus increased optical absorption. The dark current of the MoS2 film was very small. This may be due to the low background carrier concentration. The photo-generated holes recombined with the surface-adsorbed oxygen ions. The results show that hole and electron pairs were generated when UV light illuminated the ZnO layer. PD devices based on MoS2 thus exhibit a very high photoresponsivity [1, 17]. The high performance can be ascribed to the straight electron transport path offered by nanocrystalline MoS2 powders. The MoS2 nanopowders have a high surface-to-volume ratio. A heterojunction forms at the interface between ZnO and MoS2 nanopowders.

Figure 5 shows the photoresponsivity of pure ZnO and 5 wt% MoS2/ZnO PDs in the UV-to-visible light region. The device with MoS2 nanopowders shows a red shift (from 360 to 420 nm) and increased photocurrent. The photoresponsivity of the composite MoS2/ZnO device as a function of illumination wavelength was measured. The response increased as the illumination wavelength was reduced from 420 to 300 nm. The higher responsivity of the 5 wt% MoS2/ZnO PD compared with that of ZnO is attributed to the improved carrier transport and collection efficiency [18]. The adsorbates on the MoS2 surface or at the MoS2/ZnO interface affect not only the carrier transport behaviors but also the photoelectrical responses [19]. The optical properties of nanocrystalline MoS2 have been measured by UV/VIS absorption spectroscopy technique. The optical absorption spectrum of MoS2 nanocrystallines shows a minimum optical absorption feature of about 400 nm and strong rising absorption edge shifts towards the UV region. Therefore, the prepared MoS2/ZnO MSM photodetectors generated photoresponse between 300 and 420 nm UV range and diminishing photoresponse at the visible range. A good agreement is observed between the MoS2 nanocrystalline absorption characteristics and the photoresponsivity data. Lopez-Sanchez et al. demonstrated ultrasensitive monolayer MoS2 phototransistors with improved device mobility and ON current [1]. A thin film of MoS2 nanocrystals has also been demonstrated through laser ablation that it could be used as a material for the fabrication of UV PDs [17]. This flexible MoS2/ZnO optoelectronic devices could be used in fields of low-light imaging sensors.

Conclusions

MoS2 nanopowder was deposited on flexible devices using high-energy ball-milling method. Flexible ZnO and MoS2/ZnO MSM PDs were investigated. The results show that the photocurrent/dark current ratios of pure ZnO and MoS2/ZnO flexible PDs were 103 and 104, respectively. The responsivity increased and the wavelength was red-shifted when a 5 wt% MoS2 layer was used. There was a significant improvement in the photo-induced properties.

References

Lopez-Sanchez O, Lembke D, Kayci M, Radenovic A, Kis A (2013) Ultrasensitive photodetectors based on monolayer MoS2. Nat Nanotech 8:497

Gu W, Shen J, Ma X (2014) Fabrication and electrical properties of MoS2 nanodisc-based back-gated field effect transistors. Nanoscale Res Lett 9:100

Kam KK, Parkinson BA (1982) Detailed photocurrent spectroscopy of the semiconducting group VIB transition metal dichalcogenides. J Phys Chem 86:463

Mak KF, Lee C, Hone J, Shan J, Heinz TF (2010) Atomically thin MoS2: a new direct-gap semiconductor. Phys Rev Lett 105:136805

Xia F, Mueller T, Lin YM, Valdes-Garcia A, Avouris P (2009) Ultrafast graphene photodetector. Nat Nanotech 4:839

Cho AJ, Park KC, Kwon YJ (2015) A high-performance complementary inverter based on transition metal dichalcogenide field-effect transistors. Nanoscale Res Lett 10:115

Yin Z, Li H, Jiang L, Shi Y, Sun Y, Lu G, Zhang Q, Chen X, Zhang H (2012) Single-layer MoS2 phototransistors. ACS Nano 6:74

Mueller T, Xia F, Avouris P (2010) Graphene photodetectors for high-speed optical communications. Nat Photon 4:297

Li Q, Newberg JT, Walther EC, Hemminger JC, Penner RM (2004) Polycrystalline molybdenum disulfide (2H-MoS2) nano- and microribbons by electrochemical/chemical synthesis. Nano Lett 4:277

Wu H, Yang R, Song B, Han Q, Li J, Zhang Y, Fang Y, Tenne R, Wang C (2011) Biocompatible inorganic fullerene-like molybdenum disulfide nanoparticles produced by pulsed laser ablation in water. ACS Nano 5:1276

Coleman JN, Lotya M, O’Neill A, Bergin SD, King PJ, Khan U, Young K, Gaucher A, De S, Smith RJ, Shvets IV, Arora SK, Stanton G, Kim HY, Lee K, Kim GT, Duesberg GS, Hallam T, Boland JJ, Wang JJ, Donegan TF, Grunlan JC, Moriarty G, Shmeliov A, Nicholls RJ, Perkins JM, Grieveson EM, Theuwissen K, McComb DW, Nellist PD, Nicolosi V (2011) Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331:568

Zhan Y, Liu Z, Najmaei S, Ajayan PM, Lou J (2012) Large-area vapor-phase growth and characterization of MoS2 atomic layers on a SiO2 substrate. Small 28:966

Hsiao YJ, Chai YL, Ji LW, Fang TH, Meen TH, Tsai JK, Chen KL, Prior SD (2012) Optical characteristics of LiZnVO4 green phosphor at low temperature preparation. Mater Lett 70:163

Peng SM, Su YK, Ji W, Young SJ, Tsai CN, Hong JH, Chen ZS, Wu CZ (2011) Transparent ZnO nanowire-network ultraviolet photosensor. IEEE Trans Electron Devices 58:2036

Hsiao YJ, Meen TH, Ji LW, Tsai JK, Wu YS, Huang CJ (2013) Preparation of ZnS microdisks using chemical bath deposition and ZnS/p-Si heterojunction solar cells. J Phys Chem Solids 74:1403

Willimason GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22

Xie Y, Wei L, Li Q, Chen Y, Yan S, Jiao J, Liu G, Mei L (2014) High-performance self-powered UV photodetectors based on TiO2 nano-branched arrays. Nanotechnol 25:075202

Alkis S, Öztaş T, Aygün LE, Bozkurt F, Okyay AK, Ortaç B (2012) Thin film MoS2 nanocrystal based ultraviolet photodetector. Opt Express 20:21815

Choi W, Cho MY, Konar A, Lee JH, Cha GB, Hong SC, Kim S, Kim J, Jena D, Joo J, Kim S (2012) High-detectivity multilayer MoS2 phototransistors with spectral response from ultraviolet to infrared. Adv Mater 24:5832

Acknowledgements

This work was partially supported by the Ministry of Science and Technology of Taiwan under grants MOST 103-2221-E-151-001-MY3 and MOST 103-2221-E-151-007-MY3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ Contributions

YJ and BY carried out the synthesis and characterization of the samples, analyzed the results, and wrote the first draft of the manuscript. TH participated in the design, preparation, and discussion of this study. LW contributed ideas for the growth of the samples and revised the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hsiao, YJ., Fang, TH., Ji, LW. et al. Red-Shift Effect and Sensitive Responsivity of MoS2/ZnO Flexible Photodetectors. Nanoscale Res Lett 10, 443 (2015). https://doi.org/10.1186/s11671-015-1151-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1151-5