Abstract

A constant current deposition method was selected to load highly dispersed Pt nanoparticles on TiO2 nanotubes in this paper, to extend the excited spectrum range of TiO2-based photocatalysts to visible light. The morphology, elemental composition, and light absorption capability of as-obtained Pt/TiO2 nanotubes electrodes were characterized by FE-SEM, energy dispersive spectrometer (EDS), X-ray photoelectron spectrometer (XPS), and UV-vis spectrometer. The photocatalytic and photoelectrocatalytic oxidation of As(III) using a Pt/TiO2 nanotube arrays electrode under visible light (λ > 420 nm) irradiation were investigated in a divided anode/cathode electrolytic tank. Compared with pure TiO2 which had no As(III) oxidation capacity under visible light, Pt/TiO2 nanotubes exhibited excellent visible-light photocatalytic performance toward As(III), even at dark condition. In anodic cell, As(III) could be oxidized with high efficiency by photoelectrochemical process with only 1.2 V positive biasing. Experimental results showed that photoelectrocatalytic oxidation process of As(III) could be well described by pseudo-first-order kinetic model. Rate constants depended on initial concentration of As(III), applied bias potential and solution pH. At the same time, it was interesting to find that in cathode cell, As(III) was also continuously oxidized to As(V). Furthermore, high-arsenic groundwater sample (25 m underground) with 0.32 mg/L As(III) and 0.35 mg/L As(V), which was collected from Daying Village, Datong basin, Northern China, could totally transform to As(V) after 200 min under visible light in this system.

Similar content being viewed by others

Background

Arsenic (As) contamination is widely recognized as a global health problem. The distribution of As(III) and As(V) in natural water depends on the redox potential and pH of water [1]. Compared with As(V), As(III) is generally reported to have a low affinity to the surface of various minerals, because it mainly exists as nonionic H3AsO3 in natural water when pH <9. Nevertheless, As(V) adsorbs easily to solid surfaces, so it is easier to be removed. Since As(III) is more toxic and more difficult to remove than As(V), a pre-oxidation technology by transforming As(III) to As(V) is highly desirable to remove arsenic from water [2].

Kinds of treatment methods have been reported on oxidizing As(III) to As(V), including biological oxidation, chemical oxidation with conventional oxidants, such as chlorine, chlorine dioxide (ClO2), chloroamine (NH2Cl), permanganate (MnO4 −), manganese oxides, and hydrogen peroxide [3], photo-oxidation using ultraviolet and visible light radiation, and photocatalytic oxidation [4]. Among these techniques, the photocatalytic oxidation of As(III) to As(V) is newly developed and becoming a promising method. Up to now, the photocatalysts used for oxidizing As(III) reported in literatures are TiO2 [5, 6], BiOI [7], and WO3 [8], and TiO2 is widely used for As(III) oxidation. Photocatalytic oxidation of As(III) in TiO2 suspensions has been proved to be an efficient and environmentally acceptable technique [9–12]. Rapid oxidation from As(III) to As(V) could be realized in TiO2 suspensions, e.g., a 10 mg/L of As(III) could be totally oxidized to As(V) within minutes under UV irradiation [13]. TiO2 is limited as an efficient photocatalyst because of its wide band gap (3.2 eV) and high recombination rate of photogenerated electron-hole pairs. So, how to expand the absorption band of TiO2-based photocatalysts to visible light range or reduce the recombination of electron-hole pairs are key points in using TiO2-based materials as highly efficient photocatalysts.

Numerous attempts have been devoted to extend the photo response range of TiO2 to visible spectral area. For instance, TiO2-based photocatalysts were modified by doping with metal cations [14] or nonmetal ions [15], photosensitizing with dyes on the TiO2 surface, depositing noble metals [16], or coupling with another semiconductor (such as CdS, Fe2O3, ZnO, and SnO2) [17, 18]. Up to now, TiO2-based nanoparticles functionalized with Fe [19], γ-Fe2O3 [20], Mn3O4 [21] and MoOx [22], and sensitized with ruthenium dye [23, 24] have been used for arsenite oxidation and all exhibited better photocatalytic oxidation performance for arsenite than pure TiO2. Among these studies, the deposition of Pt nanoparticles on TiO2 was proved to have a high photocatalytic activity [25]. Pt doping of TiO2 can form the Schottky barrier among the metals and the electronic potential barrier at the metal-semiconductor heterojunction, and the platinized TiO2 can trap the photogenerated electrons efficiently [26, 27]. Furthermore, Pt-doped TiO2 materials produce significantly higher photocatalytic activity under visible light irradiation, while the photocatalytic activity under UV irradiation is improved slightly.

To reduce the recombination of photogenerated electron-hole pairs, the technique of photoelectrocatalytic oxidation has attracted increasing attention in the field of environmental protection. Photoelectrocatalytic oxidation techniques were first applied in As(III) oxidation under UV irradiation by Fei et al., and the application of an external positive bias voltage on the catalyst could draw the photo-generated electrons away via the external circuit, leaving the holes for oxidation of As(III). Therefore, compared to the photocatalytic process, the probability of the rapid recombination of electron-hole pairs is largely reduced and the photo-oxidation ability for As(III) can be raised in the photoelectrocatalytic process [28]. Later, dye-sensitized photoelectrocatalytic oxidation over nanostructured TiO2 film electrodes were applied in As(III) transformation under visible light by Li et al. and showed a high photocatalytic activity for As(III) oxidation [23, 24, 29].

Compared with TiO2 film as a photocatalytic electrode, TiO2 nanotube arrays fabricated by electrochemical anodization have been demonstrated to be a promising photoanode because of their good physical and chemical properties, large specific surface area, facile synthesis process, and high stability in acidic and alkaline solutions [30, 31]. So, TiO2 nanotubes are widely used as photoelectric catalytic electrode instead of TiO2 film, and also usually used as novel and stable support for the noble metal catalysts. It has been demonstrated that Pt dopant can also improve the photoelectrochemical performance of TiO2 nanotubes under visible light irradiation [32]. Up to now, TiO2 nanotubes and Pt/TiO2 nanotubes have not been used in photocatalytic oxidation for As(III).

In this paper, constant current deposition [32] method was selected to synthesize Pt/TiO2 nanotubes electrode, which was proved to have smaller band gap and stronger absorption in visible light region. These Pt/TiO2 nanotubes materials were firstly tried to photoelectrocatalytic oxidation for As(III) in water driven by visible light. The photoelectrochemical oxidation performances of these materials for As(III) separately under visible light and sunlight were tested. The kinetics process of As(III) photoelectrochemical oxidation was analyzed to fit the pseudo-first-order reaction model equation. Real sample from Daying Village, Datong basin, Northern China, with high concentration of As(III) was tried by this system under visible light, and all As(III) was found to be transformed into As(V) in 200 min.

Methods

Reagents

All reagents were obtained from Sinopharm Chemical Reagent Co., Ltd. and were the highest grade available. All solutions and subsequent dilutions were prepared using deionized water from a scientific nanopure water purifier (Thermo fisher, America) with a resistivity of less than 0.055 μS/cm. A 1000 mL of As(III) standard solution (1000 mg/L) was prepared by dissolving 1.3203 g of As2O3 in the minimum amount of 4.0 M NaOH and then adjusting pH to 3.0 with 1.0 M H2SO4.

Instruments

The morphology of the samples was studied with the use of a Hitachi SU8010 field emission scanning electron microscope (FE-SEM).

The analysis of the optical properties was performed on a U-4100 UV-vis spectrophotometer (Hitachi, Japan) in the region of 200–800 nm.

X-ray photoelectron spectroscopy (XPS) analysis was carried out to determine the surface properties of the catalysts using a Physical Electronics PHI model 5700 instrument (a RBD upgraded PHI-5000 C ESCA system, PerkinElmer, America), with Al X-ray source operating at 250 W. The takeoff angle of the sample to analyzer was 45°. Survey spectra were collected at pass energy (PE) of 187.85 eV over a binding energy range from 0 to 1300 eV. High binding energy resolution multiplex data for the individual elements were collected at a PE of 29.55 eV. During all XPS experiments, the pressure inside the vacuum system was maintained at 1 × 10−9 Pa. Before the above analysis, all samples were dried under vacuum at 80 °C overnight. Binding energies were calibrated by using the containment carbon (C1s = 284.6 eV).

To detect concentration of arsenic, an ELAN DRC II ICP-MS (PerkinElmer, America) equipped with an atomizer and a spray chamber was used. The ICP-MS normal operating parameters were as follows: RF power 1100 W, lens voltage 7.25 V, nebulizer gas flow rate 0.98 L/min, auxiliary gas flow rate 1.2 L/min, and plasma gas flow rate 15.00 L/min. Arsenic species were separated by Series 200 HPLC (PerkinElmer, America) with an automatic sample injector and directly introduced into ICP-MS. A C8 chromatographic column (PerkinElmer, America) was used with the mobile phase containing 1 mM tetrabutylammonium hydroxide, 0.05 mM dipotassium EDTA, and 0.05 % methanol (pH 6.8).

Preparation of TiO2 Nanotubes and Pt/TiO2 Nanotubes

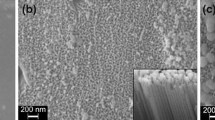

Titania nanotubular membranes were fabricated from titanium foil of 0.30 mm thickness (99.9 % pure, Erli, China). Prior to membrane fabrication, the titanium foil was polished with abrasive paper for metallograph, and then ultrasonically cleaned with acetone, ethanol, and de-ionized water, separately for 15 min, and then dried. Then the cleaned titanium foil was set into an electrolyte composed with 0.3 wt.% ammonium fluoride and 2 vol.% water in ethylene glycol. Potentiostatic anodization was done at room temperature with titanium foil (2.0 cm × 3.8 cm) as anode and graphite plate (2.5 cm × 4.5 cm) as cathode. A GPC-6030D constant-voltage DC source (GWinstek, China) was used as the voltage source to drive the anodization. After electrochemical anodic oxidation at voltage of 30.0 V for 2 h, 3.7-μm thick layer of aligned amorphous TiO2 nanotubes with 95 ± 5 nm diameters would be presented on Ti sheet. Prepared TiO2 nanotubes were ultrasonically cleaned in deionized water for 1–2 min to remove surface debris. Then amorphous TiO2 nanotubes layers were converted to the anatase phase by annealing at 450 °C [33]. SEM images of prepared TiO2 nanotubes were shown in Fig. 1.

Figure 1a shows the morphology of unwashed TiO2 nanotubes after annealing treatment; b–d give the top- and cross-sectional view of washed TiO2 nanotubes.

Pt electrodeposition was carried out by using a CS300 electrochemical workstation (Koster, China) with a standard three-electrode system. TiO2 nanotubes served as the working electrode, an Ag/AgCl electrode and a graphite plate electrode served as the reference and counter electrode, respectively. Low negative current density (−0.2, −0.3, −0.4, −0.5, −0.6, −0.7, −0.8 mA cm−2) with different current-on time was employed to deposit Pt on TiO2 nanotubes in the electrolyte. The electrolyte was a mixture of H2PtCl6·6H2O (1.0 g/L), HCl (0.1 mol/L) at 50 °C, pH = 1.0.

Although no obvious Pt particles were observed from the SEM results of Pt/TiO2 nanotubes (Fig. 2), energy dispersive spectroscopy (EDS) analysis proved that Pt nanoparticles were existed and focused on the tube wall close to the nozzle (Table 1). Furthermore, from EDS results, the deposition amount of Pt nanoparticles were found steadily increased with the applied current density of Pt deposition.

To further confirm the composition of prepared Pt/TiO2 nanotubes, XPS was introduced to detect the surface composition of samples (as shown in Fig. 3). In Fig. 3a, the two peaks at 458.5 and 464.1 eV were assigned to the Ti (2p3/2) and Ti (2p1/2) states in Pt/TiO2 nanotubes, respectively [34]. According to literature, binding energy of Ti4+(2p3/2) and Ti3 +(2p3/2) in titanium dioxide was 459 and 457 eV, respectively. The slight peak shift toward low energy suggested that the existence of small amount of Ti3+ in the Pt/TiO2 nanotubes. The strong peak centered at 529.7 eV corresponded to O(1s) bonded to titanium (Fig. 3b). Compared with the standard O(1s) peak located at 530.0 eV in the XPS spectra of pure TiO2 samples, the peak exhibited a 0.3 eV shift to lower energy, which were similar with results reported by Xing et al. [35]. Such shift can be attributed to the lack of oxygen in the Pt/TiO2 nanotubes, and oxygen vacancies will be produced with the generation of Ti3+ during the preparation process. Ti3+ and oxygen vacancies could be generated in the anneal process of TiO2 nanotubes and the Pt deposition process, because in the anneal process of TiO2 nanotubes oxygen vacancies could not be fully eliminated in current fabrication procedures [36]; at the same time, partial Ti4+ would be transformed into Ti3+ during the deposition of Pt and Pb with the interaction between Pt/Pb and TiO2 [37, 38]. The two peaks located at 70.4 and 74.3 eV shown in Fig. 3c could be assigned to Pt (4f7/2) and Pt (4f5/2), respectively [39], which indicated that Pt was deposited on the TiO2 nanotubes substrate successfully. The binding energy peaks at 70.4 and 74.3 eV are a little higher than that of free Pt nanoparticles (70.3 and 73.6 eV) due to the electrostatic interaction between Pt nanoparticles and TiO2 nanotubes [40]. The two Pt4f peaks could be divided into four separated peaks attributed to Pt0 (4f7/2), Pt2+ (4f7/2), Pt0 (4f5/2), and Pt2+ (4f5/2), and it was found that Pt0 was the dominant species in Pt deposited on TiO2 nanotubes [41].

In order to determine the photo-absorbance properties, the UV-vis diffuse reflectance spectra (DRS) of pure TiO2 nanotubes and Pt/TiO2 nanotubes was analyzed from 200 to 800 nm wavelengths, as shown in Fig. 4. TiO2 nanotubes exhibited a photo-response in ultraviolet region with wavelengths below 390 nm, which could be attributed to intrinsic band gap of TiO2. The weak absorption of TiO2 nanotubes within the visible light range could be ascribed to the scattering of light caused by pores or cracks in the nanotube arrays or the presence of oxygen vacancies and Ti3+ species in the synthesized TiO2 nanotubes. Previous researches [36] indicated that in the anneal process of TiO2 nanotubes oxygen vacancies and Ti3+ species could not be fully eliminated with the current fabrication procedures. Ti3+ species could accelerate the formation of isolated defect energy level below the bottom of the conduction band (CB) of TiO2, and also absorbed visible light, which would excite and produce photo-generated electrons transforming from Ti3+ states to CB of TiO2. The weakly visible light absorption of TiO2 nanotubes further indicated that oxygen vacancies and Ti3+ species probably occurred during the anneal process of TiO2 nanotubes. When Pt nanoparticles were loaded on TiO2 nanotubes, the photoabsorption amount of the catalyst in visible light region increased and the amount of photoabsorption in the ultraviolet light range decreased. This result was similar to the findings of previous investigations [31]. Compared with pure TiO2 nanotubes, the photosensitivity of Pt/TiO2 nanotubes in the visible and near visible light wave range increased, because of localized surface plasmon resonance (LSPR) of Pt nanoparticles on the pore-wall of TiO2 nanotubes. These results proved, when Pt nanoparticles were loaded on TiO2 nanotubes as inorganic sensitizer, the LSPR of Pt nanoparticles promoted the separate efficiency of photogenerated charges and extended the range of the excited spectrum. According to XPS spectrum results, it was demonstrated that oxygen vacancies and Ti3+ species were present in Pt/TiO2 nanotubes, which induced broad visible light absorption of Pt/TiO2 nanotubes. So, Pt/TiO2 nanotubes can be tested under visible light to oxidate As(III).

Photocatalytic Activity Tests

Photocatalytic activities for As(III) oxidation were conducted in a 50-ml quartz beaker. The initial As(III) concentration was fixed at 3.4 mg/L, and the pH was adjusted with H2SO4 or NaOH solution to the desired value. Prior to As(III) oxidation, TiO2 nanotubes was added in the solution and kept for 30 min to allow equilibrium adsorption of arsenite on TiO2 nanotubes. UV light irradiation was applied by a 175-W high-pressure mercury lamp, and visible light source was a 300-W halogen lamp (Philips, Holland) equipped with a wavelength cutoff filter for λ ≤ 420 nm. Water samples were withdrawn by a 1.0 mL pipette intermittently during photoreaction and filtered through 0.22-μm PTFE filters (Millipore). Duplicate or triplicate experiments were performed for each set.

Photoelectrocatalytic Activity Tests

Photoelectrocatalytic oxidation of As(III) was performed in a self-made divided electrolytic tank (Fig. 5a). The anode tank and the cathode tank were isolated, and formed a circuit by a salt bridge. The CS300 electrochemical workstation (Koster, China) was employed to provide constant positive bias voltages, meanwhile, recorded the corresponding current. The Pt/TiO2 nanotubes served as working electrodes, with 2.0 × 3.8 cm2 area. A saturated calomel electrode and a graphite rod served as reference electrode and auxiliary electrode, respectively. A 50.0 mL electrolyte was comprised of 0.1 M Na2SO4 (as supporting electrolyte) and As(III) with 2.0, 2.8, 3.4, 4.0, 5.0, and 6.0 mg/L initial concentration. Prior to As(III) oxidation, Pt/TiO2 nanotubes working electrode was kept in the electrolyte under darkness for 30 min to ensure adsorption equilibrium. The light source was provided by the 300-W halogen lamp (Philips, Holland) in full wavelength range with illumination intensity around 453 mW cm−2 (Fig. 5b). The photocatalytic activity under visible light irradiation (the 300-W halogen lamp) was tested with a cutoff filter to get rid of UV irradiation below 420 nm. To avoid the heating effect caused by the infrared irradiation, the quartz cell was cooled down by circulating water.

Results and Discussion

Photocatalytic Oxidation for As(III) by Pt/TiO2 Nanotubes Prepared with Different Current Density and Pt Deposition Time

The effect of Pt loading time on photocatalytic oxidation As(III) was tested at 25 °C constant temperature in 3.4 mg/L As(III) solution under visible light for 360 min as shown in Fig. 6a. When the Pt loading time were 2.5, 5, 10, and 20 min, the percentages of final dissolved As(V) in system were 77.3, 83.9, 88.1, and 85.9, respectively. Results showed that with the increase of Pt loading time, the oxidation rate of As(III) first increased, then decreased with extensive loading. Considering the economic reason and As(III) oxidation efficiency, the optimal Pt loading time in the following experiments was focused at 5 min.

Figure 6b shows the effect of Pt deposition current density in As(III) photocatalytic oxidation process. When current density of the Pt deposition was increased from 0.2 to 0.8 mA cm−2, percentages of final dissolved As(V) were varied from 74.1 to 83.8 %. Concentration of generated As(V) first increased with the increase of applied current density of Pt deposition when it was below 0.4 mA cm−2. This is because both the valence state of Pt loaded on Pt/TiO2 nanotubes, and the deposition quantity will increase with the applied current density. Photocatalytic activity of platinized TiO2 was arranged in the order of Pt (0)/TiO2 > PtOx (II, IV)/TiO2 > bare TiO2 [42]. When applied current density increased to 0.5 mA cm−2, the photocatalytic ability of Pt/TiO2 nanotubes for As(III) oxidation was kept stable. To the following experiments, the applied current density was kept at 0.5 mA cm−2.

Photocatalytic Ability Comparison Between Naked TiO2 Nanotubes and Pt/TiO2 Nanotubes

To prove the function of Pt for photocatalysis, oxidation abilities of As(III) were compared between TiO2 and Pt/TiO2 nanotubes under visible light irradiation or visible light irradiation with 1.2 V positive biasing. From Fig. 7a, we could find that under visible light, no As(III) was oxidized by TiO2 nanotubes, no matter if 1.2 V positive biasing was applied. While, under ultraviolet light, 82.0 % of As(III) could be oxidized to As(V) after 30 min. This means, only under ultraviolet light condition, TiO2 nanotubes have photocatalytic oxidation ability for As(III).

a Comparison of As(III) photocatalytic oxidation on TiO2 nanotubes under visible light and UV. Comparison of As(III) (b) and As(V) (c) concentration in system with photocatalytic and photoelectrocatalytic process on Pt/TiO2 nanotubes. d Concentration of arsenic species in photocatalytic system and photoelectrocatalytic anodic/cathodic cells with Pt/TiO2 nanotubes after 280 min

To Pt/TiO2 nanotubes electrodes prepared at 0.5 mA cm−2 with 5 min, they displayed high photocatalytic and photoelectrocatalytic oxidation activity for As(III) (Fig. 7 b). To avoid the influence of adsorption effect of Pt/TiO2 nanotubes, 30 min equilibrium adsorption was first operated before catalytic experiments, which made As(III) concentration decrease from 3.41 to 3.20 mg/L. When both electrochemical and photocatalytic processes were simultaneously applied, 94.2 % of As(III) could be oxidized in 280 min. This value was 13.5 % higher than the only photocatalytic oxidation process. Fabricated Pt nanoparticles were acted as electron traps, which could enhance the separation of electron-hole pairs, and the external positive biasing drove electron (e −) to cathode, then the recombination of electron-hole pairs could be further reduced. So, more holes could cause stronger direct (h+) oxidation or indirect (HO·) oxidation for As(III) on anode Pt/TiO2 nanotubes electrode, which was the reason why the As(III) oxidation rate on anode in the photoelectrocatalytic process was higher than that in the photocatalytic process. In addition, an interesting phenomenon was found on Pt/TiO2 nanotubes, As(III) even could be oxidized in dark condition. And 17.4 % of As(III) could be converted into As(V) in 280 min, this could be induced by catalytic effect of platinum itself, and O2 activation on Pt nanoparticles might be responsible for this dark activity. When 1.2 V of positive biasing was applied under dark condition, the oxidation efficiency of As(III) to As(V) was hardly improved.

With detection solution in cathode cell, it was interesting to find that As(III) was also continuously transformed into As(V) during the photoelectrocatalytic process at reduction potential. When 1.2 V of positive bias potential was applied to this system, the conversion rate in cathode cell was 66.4 % after 280 min (Fig. 7d).

Effect of Initial As(III) Concentration on Photoelectrocatalytic Result of Pt/TiO2 Nanotubes Electrode

Figure 8a showed the oxidation rate of As(III) increased obviously with the rise of initial As(III) concentration.

Furthermore, the kinetics simulation curves of As(III) photoelectrocatalytic oxidation were summarized and presented in Fig. 8b. All oxidation reactions were well fitted in the pseudo-first-order kinetics model.

where C is the concentration of As(III) (mg/L), t is the reaction time (min), and k app is the apparent first order reaction constant (min−1). The values of k app and the regression correlation coefficient R 2 of Pt/TiO2 nanotubes for As(III) photoelectrocatalytic oxidation were listed in Table 2. Correlation coefficient (R 2) values of pseudo-first-order kinetic model with different initial As(III) concentration were all more than 0.980. This meant that photoelectrocatalytic oxidation process of As(III) on Pt/TiO2 nanotubes obeyed pseudo-first-order kinetics equation.

The Influence of Applied Bias Potentials on the Photoelectrocatalytic Oxidation of As(III)

The bias potential is an important parameter in the process of photoelectrocatalytic activity. Photo-generated electrons on Pt/TiO2 nanotubes electrode could be driven to the counter electrode with positive potential. So, bias potentials ranged from 0.0 to 2.0 V were monitored over 280 min in photoelectrocatalytic oxidation treatment (Fig. 9).

Figure 9a illustrated that As(III) oxidation rate increased with the increase of applied positive bias. With applied 0.0 to 2.0 V positive bias, the plot of C t versus time was fitted with exponential decay equation with all R 2 exceeding 0.980. The apparent As(III) oxidation rate constants were varied from 7.2 × 10−3 to 12.4 × 10−3 min−1. Applying a positive biasing to the Pt/TiO2 nanotubes electrode can transfer the photo-generated electrons away from photo-generated holes on the Pt/TiO2 nanotubes electrode via the external circuit; thus, the recombination of photo-generated electron-hole pairs is minimized [43, 44].

In Fig. 9a, it was found that in the range of studied positive biasing, rate constant linearly went up with the increase of applied bias voltage. With the positive bias voltage increasing, more and more photo-generated electrons moved to counter electrode. As a result, the photo-generated electrons and holes were well separated, thus more hydroxyl radicals (HO·) could be produced by H2O oxidized in the holes [45]. Which species (h+, HO· and ·O2 −) was mainly responsible for the oxidation from As(III) to As(V) in the UV/TiO2 system, different opinions had been proposed on this issue. But so far, it still remained as a controversial issue [46]. So, on the anode Pt/TiO2 nanotubes electrode, it was in dispute whether h+ or HO· was responsible for As(III) oxidation.

At the same time, the oxidation rate of As(III) to As(V) on graphite rod in cathodic cell was also verified to increase with applied potential (Fig. 9b). After 280 min, As(V) concentration were 0, 0.84, 0.96, 1.69, 2.15, 3.02, and 3.39 mg/L when system was applied with 0.0, 0.3, 0.6, 0.9, 1.2, 1.5, and 2.0 V positive bias potentials. As(III) in cathodic cell could be completely transformed into As(V) after 280 min when system was applied with 2.0 V positive bias potential. Leng et al. found that the main product of oxygen reduction reaction was hydrogen peroxide (H2O2) on the cathode graphite in aqueous solution with pH from 2 to 12 [47]. Nevertheless, ·O2 − was only stable in concentrated alkaline solutions or aprotic media. So, it was inferred that e- on cathode electrode could be trapped by the surface absorded O2 to generate H2O2 as Eq. (1), which had powerful oxidation ability to convert As(III) to As(V) as Eq. (2) [47].

The Effect of Solution pH Value on As(III) Oxidation

The influence of initial pH on photocatalytic oxidation of As(III) in anodic cell was shown in Fig. 10a. The oxidation rate in alkaline environment was mostly a little faster than the rate in acid environment. The result differed from that of Lee and Choi [48] who found that the initial oxidation rate at pH 9 was about twice as fast as the rate at pH 3, and also differed with the result of Bissen et al. [13] and Sharma et al. [49] who both found that the small increase in the oxidation of As(III) with increasing pH was within experimental error.

The potential of As(V)/As(III) couple is much less positive than the valence band potential of TiO2, so, the photo-generated holes have enough thermodynamic potential to oxidize As(III) to As(V) [50]. The potential of As(V)/As(III) couple in alkaline environment is lower than that in acid, which may be contributed to the increase of the oxidation rate with the increase of pH.

The pH change during the photoelectrocatalytic oxidation of As(III) in aqueous solution was displayed in Fig. 10b. During the electrochemical experiment, pH decreased with irradiation time during both photocatalysis and photoelectrocatalysis experiments. The decrease of pH in the photoelectrocatalysis experiment was faster than that in the photocatalysis.

The influence of pH on the speciation of arsenic oxoanions can easily be obtained from Eq. (3) to (8), acid dissociation constants are also given.

In the photocatalytic process, As(III) was oxidized to As(V), meanwhile, protons were produced, and the reaction could be described as

In photoelectrocatalytic process, the anode oxidation caused O2 evolution in anode cell, which produced protons and contributed to the further reduce of the pH during photoelectrocatalytic activity.

Photoelectrocatalytic Oxidation of As(III) by Natural Sunlight

To further extend the photoelectrocatalytic applicability of Pt/TiO2 nanotube arrays electrode in a more practical situation, the photoelectrocatalytic oxidation ability was also evaluated under natural sunlight. Figure 11a showed the evolution of As(III)/As(V) concentration with irradiation time with initial 3.4 mg/L As(III) and 1.2 V positive bias potential under natural sunlight irradiation. The photoelectrocatalytic oxidation process under natural sunlight accorded with zero-order kinetics law (C t = − 0.0114t + 2.9971(R 2 = 0.973)), different with process under visible light which followed first-order kinetics law. As(III) could be completely oxidized after 280 min under natural sunlight irradiation. While, to visible light, it needed 360 min to totally oxidize As(III). This might be because of the effect of ultraviolet light in sunlight.

Photoelectrocatalytic Oxidation of As(III) in High Arsenic Groundwater Sample Under Visible Light

The photoelectrocatalytic activity of real groundwater sample with high arsenic was also investigated by Pt/TiO2 nanotubes arrays electrode under visible light. The high arsenic underground water sample (25 m underground) was collected from Daying Village, Datong basin, Northern China, concentrations of main ions in this water sample was determined as follows: Na+ 324.2 mg/L, Ca2+ 35.8 mg/L, Mg2+ 61.5 mg/L, Cl− 297.4 mg/L, HCO3 − 544.1 mg/L, SO4 2− 275.5 mg/L, NO2 − 1.10 mg/L, Fe2+ 0.75 mg/L, NH4 + 0.81 mg/L, S2− 74.9 μg/L, As(III) 0.32 mg/L, As(V) 0.35 mg/L, 8.32 of pH, and 2.3 mS cm−2 of conductivity. After 30 min for equilibrium adsorption, 9.5 % of As(III) and 14.2 % of As(V) were adsorbed on Pt/TiO2 nanotube arrays. The conversion of As(III) during the photoelectrocatalytic process with 1.2 V of positive bias potential was found to follow a zero-order kinetics law as C t = − 0.0015t + 0.3013 (R 2 = 0.981), and As(III) in groundwater sample was totally transformed into As(V) in 200 min under visible light. This proved Pt/TiO2 nanotubes electrode was an efficient photoelectrocatalytic material for As(III) oxidation and could be used in high arsenic underground water pretreatment (Fig. 12).

Conclusions

To promote photocatalytic oxidation of As(III) by TiO2 materials under visible light, Pt/TiO2 nanotubes were introduced via a constant current deposition method. First, the prepared nanotubes were detected by SEM, XPS to prove the existing of Pt, and UV-vis diffuse reflectance spectra results proved that Pt could promote separate efficiency and extend the excited spectrum range. Pt/TiO2 nanotubes presented more efficient photoelectrocatalytic oxidation performance for As(III) than TiO2 nanotubes. Even under dark condition, it was also useful in As(III) photoelectrocatalytic oxidation. Furthermore, the photoelectrocatalytic oxidation process under visible light was found to obey pseudo-first-order kinetics. The prominent conversion from As(III) to As(V) in cathodic cell also occurred because of the production of H2O2 from electrons trapping by O2 on cathode. While to natural sunlight, the oxidation of 3.4 mg/L As(III) on Pt/TiO2 nanotubes electrode with 1.2 V applied voltage followed zero-order kinetics law, and its oxidation rate was slightly higher than that of As(III) under visible light. As(III) in real groundwater sample could be totally transformed into As(V) in 200 min by Pt/TiO2 nanotubes electrode with 1.2 V under visible light and also accorded with zero-order kinetics.

References

Smedley PL, Kinniburgh DG (2002) A review of the source, behaviour and distribution of arsenic innatural waters. Appl Geochem 17:517–568

Zhang P, Tong M, Yuan S, Liao P (2014) Transformation and removal of arsenic in groundwater by sequential anodic oxidation and electrocoagulation. J Contam Hydrol 164:299–307

Onnby L, Kumar PS, Sigfridsson KGV, Wendt OY, Carlson S, Kirsebom H (2014) Improved arsenic(III) adsorption by Al2O3 nanoparticles and H2O2: evidence of oxidation to arsenic(V) from X-ray absorption spectroscopy. Chemosphere 113:151–157

Xu Z, Meng X (2009) Size effects of nanocrystalline TiO2 on As(V) and As(III) adsorption and As(III) photooxidation. J Hazard Mater 168:747–752

Tsimas ES, Tyrovola K, Xekoukoulotakis NP, Nikolaidis NP, Diamadopoulos E, Mantzavinos D (2009) Simultaneous photocatalytic oxidation of As(III) and humic acid in aqueous TiO2 suspensions. J Hazard Mater 169:376–385

López-Muñoz MJ, Revilla A, Alcalde G (2015) Brookite TiO2-based materials: synthesis and photocatalytic performance in oxidation of methyl orange and As(III) in aqueous suspensions. Catal Today 240:138–145

Hu J, Weng S, Zheng Z, Pei Z, Huang M, Liu P (2014) Solvents mediated-synthesis of BiOI photocatalysts with tunable morphologies and their visible-light driven photocatalytic performances in removing of arsenic from water. J Hazard Mater 264:293–302

Kim J, Moon G, Kim S, Kim J (2015) Photocatalytic oxidation mechanism of arsenite on tungsten trioxide under visible light. J Photoch Photobio 311:35–40

Ferguson MA, Hering JG (2006) TiO2-photocatalyzed As(III) oxidation in a fixed-bed, flow-through reactor. Environ Sci Technol 40:4261–4267

Ryu J, Choi WY (2006) Photocatalytic oxidation of arsenite on TiO2: understanding the controversial oxidation mechanism involving superoxides and the effect of alternative electron acceptors. Environ Sci Technol 40:7034–7039

Li Y, Cai X, Guo J, Na P (2014) UV-induced photoactive adsorption mechanism of arsenite by anatase TiO2 with high surface hydroxyl group density. Colloids Surf A Physicochem Eng Asp 462:202–210

Lee S, Kim K, Choi H, Takahashi Y (2015) Simultaneous photooxidation and sorptive removal of As(III) by TiO2 supported layered double hydroxide. J Environ Manage 161:228–236

Bissen M, Vieillard-Baron MM, Schindelin AJ, Frimmel FH (2001) TiO2-catalyzed photooxidation of arsenite to arsenate in aqueous samples. Chemosphere 44:751–757

Sun B, Shi T, Peng Z, Sheng W, Jiang T, Liao G (2013) Controlled fabrication of Sn/TiO2 nanorods for photoelectrochemical water splitting. Nanoscale Res Lett 8:462

Shi W, Yang W, Li Q, Gao S, Shang P, Shang JK (2012) The synthesis of nitrogen/sulfur co-doped TiO2 nanocrystals with a high specific surface area and a high percentage of {001} facets and their enhanced visible-light photocatalytic performance. Nanoscale Res Lett 7:1–9

Xu J, Xiao X, Stepanov AL, Ren F, Wu W, Cai G et al (2013) Efficiency enhancements in Ag nanoparticles-SiO2-TiO2 sandwiched structure via plasmonic effect-enhanced light capturing. Nanoscale Res Lett 8:73

Sun H, Zhao P, Zhang F, Liu Y, Hao J (2015) Ag2S/CdS/TiO2 nanotube array films with high photocurrent density by spotting sample method. Nanoscale Res Lett 10:382

Chen Y, Liu B, Chen J, Tian L, Huang L, Tu M et al (2015) Structure design and photocatalytic properties of one-dimensional SnO2-TiO2 composites. Nanoscale Res Lett 10:1–6

Li Y, Cai X, Guo J, Zhou S, Na P (2015) Fe/Ti co-pillared clay for enhanced arsenite removal and photo oxidation under UV irradiation. Appl Surf Sci 324:179–187

Yu L, Peng X, Ni F, Li J, Wang D, Luan Z (2013) Arsenite removal from aqueous solutions by γ-Fe2O3-TiO2 magnetic nanoparticles through simultaneous photocatalytic oxidation and adsorption. J Hazard Mater 246–247:10–17

Cai X, Li Y, Guo J, Liu S, Na P (2014) Mn(IV) promotion mechanism for the photocatalytic oxidation of arsenite by anatase-TiO2. Chem Eng J 248:9–17

Vaiano V, Iervolino G, Sannino D, Rizzo L, Sarno G, Farina A (2014) Enhanced photocatalytic oxidation of arsenite to arsenate in water solutions by a new catalyst based on MoOx supported on TiO2. Appl Catal Environ 160–161:247–253

Li X, Leng W (2012) Highly enhanced dye sensitized photocatalytic oxidation of arsenite over TiO2 under visible light by I− as an electron relay. Electrochem Commun 22:185–188

Li X, Leng W, Cao C (2013) Quantitatively understanding the mechanism of highly enhanced regenerated dye sensitized photooxidation of arsenite over nanostructured TiO2 electrodes under visible light by I−. J Electroanal Chem 703:70–79

Xu G, Liu H, Wang J, Lv J, Zheng Z, Wu Y (2014) Photoelectrochemical performances and potential applications of TiO2 nanotube arrays modified with Ag and Pt nanoparticles. Electrochim Acta 121:194–202

Chen H, Ku Y, Kuo Y (2007) Effect of Pt/TiO2 characteristics on temporal behavior of o-cresol decomposition by visible light-induced photocatalysis. Water Res 41:2069–2078

Huang LH, Sun C, Liu YL (2007) Pt/N-codoped TiO2 nanotubes and its photocatalytic activity under visible light. Appl Surf Sci 253:7029–7035

Fei H, Leng WH, Li X, Cheng XF, Xu YM, Zhang JQ et al (2011) Photocatalytic oxidation of arsenite over TiO2: is superoxide the main oxidant in normal air-saturated aqueous solutions? Environ Sci Technol 45:4532–4539

Li X, Leng W (2013) Regenerated dye-sensitized photocatalytic oxidation of arsenite over nanostructured TiO2 films under visible light in normal aqueous solutions: an insight into the mechanism by simultaneous (photo)electrochemical measurements. J Phys Chem C 117:750–762

Hou Y, Li X, Zou X, Quan X, Chen G (2009) Photoeletrocatalytic activity of a Cu2O-loaded self-organized highly oriented TiO2 nanotube array electrode for 4-chlorophenol degradation. Environ Sci Technol 43:858–863

Wu L, Li F, Xu Y, Zhang JW, Zhang D, Li G et al (2015) Plasmon-induced photoelectrocatalytic activity of Au nanoparticles enhanced TiO2 nanotube arrays electrodes for environmental remediation. Appl Catal B-Environ 164:217–224

Su Y, Deng Y (2011) Effect of structure on the photocatalytic activity of Pt-doped TiO2 nanotubes. Appl Surf Sci 257:9791–9795

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nature 238:37–38

Panayotov DA, Morris JR (2008) Catalytic degradation of a chemical warfare agent simulant: reaction mechanisms on TiO2-supported Au nanoparticles. J Phys Chem C 112:7496–7502

Xing L, Jia J, Wang Y, Zhang B, Dong S (2010) Pt modified TiO2 nanotubes electrode: preparation and electrocatalytic application for methanol oxidation. Int J Hydrogen Energy 35:12169–12173

Guo Z, Prezhdo OV, Hou T, Chen X, Lee S, Li Y (2014) Fast energy relaxation by trap states decreases electron mobility in TiO2 nanotubes: time-domain Ab initio analysis. J Phys Chem Lett 5:1642–1647

Vijayan BK, Dimitrijevic NM, Wu J, Gray KA (2010) The effects of Pt doping on the structure and visible light photoactivity of titania nanotubes. J Phys Chem C 114:21262–21269

Li FB, Li XZ (2002) The enhancement of photodegradation efficiency using Pt-TiO2 catalyst. Chemosphere 48:1103–1111

Yen CH, Shimizu K, Lin Y, Bailey F, Cheng IF, Wai CM (2007) Chemical fluid deposition of pt-based bimetallic nanoparticles on multiwalled carbon nanotubes for direct methanol fuel cell application. Energy Fuel 21:2268–2271

Wen D, Guo S, Zhai J, Deng L, Ren W, Dong S (2009) Pt nanoparticles supported on TiO2 colloidal spheres with nanoporous surface: preparation and use as an enhancing material for biosensing applications. J Phys Chem C 113:13023–13028

Gan WY, Friedmann D, Amala R, Zhang S, Chiang K, Zhao H (2010) A comparative study between photocatalytic and photoelectrocatalytic properties of Pt deposited TiO2 thin films for glucose degradation. Chem Eng J 158:482–488

Lee J, Choi W (2005) Photocatalytic reactivity of surface platinized TiO2: substrate specificity and the effect of Pt oxidation state. J Phys Chem B 109:7399

Paschoal FMM, Anderson MA, Zanoni MVB (2009) The photoelectrocatalytic oxidative treatment of textile wastewater containing disperse dyes. Desalination 249:1350–1355

Oliveira HG, Nery DC, Longo C (2010) Effect of applied potential on photocatalytic phenol degradation using nanocrystalline TiO2 electrodes. Appl Catal B-Environ 93:205–211

Grzechulska J, Morawski AW (2002) Photocatalytic decomposition of azo-dye acid black 1 in water over modified titanium dioxide. Appl Catal B-Environ 36:45–51

Yoon SH, Lee JH (2005) Oxidation mechanism of As(III) in the UV/TiO2 system: evidence for a direct hole oxidation mechanism. Environ Sci Technol 39:9695–9701

Leng WH, Zhu WC, Ni J, Zhang Z, Zhang JQ, Cao CN (2006) Photoelectrocatalytic destruction of organics using TiO2 as photoanode with simultaneous production of H2O2 at the cathode. Appl Catal Gen 300:24–35

Lee H, Choi W (2002) Photocatalytic oxidation of arsenite in TiO2 suspension: kinetics and mechanisms. Environ Sci Technol 36:3872–3878

Sharma VK, Dutta PK, Ray AK (2007) Review of kinetics of chemical and photocatalytical oxidation of Arsenic(III) as influenced by pH. J Environ Sci Heal A 42:997–1004

Chen D, Ray AK (2001) Removal of toxic metal ions from wastewater by semiconductor photocatalysis. Chem Eng Sci 56:1561–1570

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 40902070), and the Fundamental Research Funds for the Central Universities (No. CUG110414).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Competing Interests

The authors declare that they have no competing interests.

Authors’ Contributions

YQ prepared the nanomaterials, carried out the structural analyses of the samples, and drafted the manuscript. YC designed the experiments, YC and YL guided YQ for the experimental section, and YC edited the whole manuscript. ZT and YW took part in the experimental section. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Qin, Y., Li, Y., Tian, Z. et al. Efficiently Visible-Light Driven Photoelectrocatalytic Oxidation of As(III) at Low Positive Biasing Using Pt/TiO2 Nanotube Electrode. Nanoscale Res Lett 11, 32 (2016). https://doi.org/10.1186/s11671-016-1248-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1248-5