Abstract

Nb-doped SrTiO3 ceramics doped with the surface modification of nanosized titania was prepared via liquid phase deposition approach and subsequent sintered in an Ar atmosphere. The surface modification of nanosized titania significantly improved the ratio of the electrical conductivity to thermal conductivity of SrTiO3 ceramic doped with Nb, and has little impact on the Seebeck coefficient, thus obviously improving the dimensionless thermoelectric figure of merit (ZT value). The surface modification of nanosized titania is a much better method to lower the thermal conductivity and to enhance the electrical conductivity than the mechanical mixing process of nanosized titania. The highest ZT value of 0.33 at 900 K was obtained. The reason for the improved thermoelectric performances by the surface modification of nano-sized titania was preliminary investigated.

Similar content being viewed by others

Background

More and more attentions have been paid to the bulk nanostructured thermoelectric materials due to their high thermoelectric performances [1–5]. Tang et al. reported the layer nanostructured Bi2Te3 bulk materials sintered by spark plasma sintering and combined melt spinning technique, and obtained the highest ZT value of 1.35 at 300 K [6]. Mi et al. reported that the hot pressed mixture of nanoscale and microsized CoSb3 powders formed the n-type CoSb3 nanocomposites, and reached the highest ZT value 0.71 at 700 K [7]. Poudel et al. prepared nanostructured bismuth antimony telluride alloys via ball milling and hot pressing technique, and the highest ZT value reached 1.4 at 373 K [8]. Han et al. reported Yb0.2Co4Sb12+y nanostructured bulk materials by combining melt spinning method with spark plasma sintering, and obtained the highest ZT value of 1.26 at 800 K [9]. Han et al. also fabricated n-type skutterudites In x Ce y Co4Sb12 with in situ forming nanostructured InSb phase via a melt-quench-anneal-spark plasma sintering technique, and obtained the highest ZT value of 1.43 at 800 K [10]. Kadel et al. reported Bi2Se3 nanostructures by solvothermal method and the highest ZT value obtained 0.096 at 523 K [11].

Recently, SrTiO3 thermoelectric materials with non-toxic and element-rich advantages arose wide attention [12, 13]. In our previous study, Nb-doped SrTiO3 (Nb-STO) with titanate nanotube additions fabricated via the pressure-less sintering method [14–16]. The additions were directly mixed with strontium titanate powders, which induced the inhomogenous distribution of additions and further lead to the inhomogenous thermoelectric performance of bulk ceramic. Thus, to obtain a homogenous thermoelectric performance, it is important to make a homogenous distribution of the additions.

In this study, liquid phase deposition approach was used to surface-modify Nb-STO by forming the nanosized titania on the strontium titanate grains, and its effect on the thermoelectric performances of SrTiO3 ceramic doped with Nb were investigated in detail.

Methods

SrCO3, TiO2, and Nb2O5 powders with high purity were used to prepare the single-phase Nb-doped SrTiO3 (Sr(Ti0.85Nb0.15)O3, Nb-STO) powders in an Ar atmosphere at 1400 °C for 4 h via a solid-state reaction. As-prepared Nb-STO powders were put into the aqueous solution including (NH4)2TiF6 (0.06 M) and H3BO3 (0.2 M). The slurry was strongly stirred at room temperature for 2 h. The centrifugated powders were washed several times with de-ionized water and then dried at about 80 °C. The Nb-STO powders without and with surface modification of nanosized titania were then pressed into pellets under a pressure of 20 MPa and sintered in an Ar atmosphere at 1500 °C for 3 h in a graphite crucible.

The microstructure observations were conducted using scanning electron microscopy (SEM, S-3000N, Hitachi Corporation). The thermoelectric performances, the Seebeck coefficient and electrical conductivity, were determined at 300–1000 K in an Ar atmosphere using an automatic thermoelectric measuring apparatus (RZ-2001K, Ozawa Scientific Corporation). The thermal conductivity (κ) was determined from the thermal diffusivity (β), specific heat capacity (C p), and density (ρ) using the following equation: κ = ρC p β. The thermal diffusivity was determined by the common laser flash method (TC-9000V, ULVAC-RIKO Corporation). And the specific heat capacity was determined by a differential scanning calorimeter system (DSC-2910, TA Instruments Corporation).

Results and Discussion

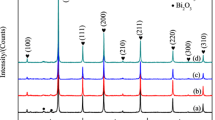

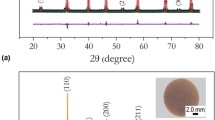

Figure 1 shows the SEM results of raw Nb-STO powders coated with nano-sized titania via liquid phase deposition. The nanosized titania prepared by liquid phase deposition, with anatase phase [17], homogeneously coated on the surface of the Nb-STO powders. Figure 2 shows the relationship between the electrical conductivity (σ)/Seebeck coefficient (S) performances and temperature of Nb-STO composites modified by nanosized titania. The results show that the electrical conductivity significantly increased by surface modification of nanosized titania (Fig. 2a). Meanwhile, it has small impacts on the Seebeck coefficient (Fig. 2b).

Figure 3 shows the relationship between the temperature and the measured thermal conductivity of Nb-STO samples with and without surface modification of nanosized titania. Although the results showed that the thermal conductivity enhanced by surface modification of nanosized titania (solid line), the relative densities of the two samples are different: the pure Nb-STO is 63.1 %, and 75.2 % with titania modified, as listed in Fig. 3. Hence, the measured thermal conductivity cannot accurately show the effect of surface modification. To eliminate the effect of porosity, the relative densities of Nb-STO samples with and without surface modification of nanosized titania are assumed to be the same, and the thermal conductivity of the was determined using Klemens’ equation [18]:

where κ 1 and κ 2 are the thermal conductivities of the samples with different porosities (φ 1□ and φ2)□, and κ 0 is the thermal conductivity of the fully dense sample. From Eqs. (1) and (2), the following relationship could be obtained:

Based on Eq. (3), the thermal conductivity of Nb-STO sample without surface modification, which has the same relative density to the sample with surface modification of nanosized titania, 75.2 %, was obtained, shown by dotted lines in Fig. 3. The results indicate that the surface modification of nanosized titania could actually reduce the thermal conductivity of Nb-STO polycrystalline ceramics, when the effect of porosity is eliminated.

The thermoelectric power factor S 2σ and dimensionless figure of merit ZT of the sampls are shown in Fig. 4. The power factor of Nb-STO composite with the surface modification of nanosized titania was increased by more than 15 times compared with the pure Nb-STO (Fig. 4a), due to the significant increases of electrical conductivity. The ZT value also improved evidently (Fig. 4b), because the enhancement of the power factor was higher than that of thermal conductivity. The highest ZT value reached 0.33 at 900 K.

Figure 5 shows the scanning electron micrographs (SEM) of Nb-STO samples with and without the surface modification of nanosized titania. It can be seen that the surface modification of nanosized titania obviously enhanced the grain growth of Nb-STO. When the sintering temperature is higher than 1250 °C, the main sintering mechanism of the SrTiO3 ceramic is the volume diffusion [19]. Nb-STO composite with the surface modification of nanosized titania induced Ti-rich composite, which created Sr and O vacancies and therefore enhanced the volume diffusion. Grain growth of Nb-STO lowered the interface scattering of the electrons, promoted carrier mobility [14], and further enhanced the electrical conductivity. It is observed that lots of pores homogeneously distributed in the Nb-STO bulk ceramic (Fig. 5b). The reason for the formation of pores was not clear until now, but these pores homogeneously distributed in the Nb-STO bulk ceramic, which could scatter phonons effectively and reduce the thermal conductivity of Nb-STO composite.

For degenerate semiconductors for which a parabolic band and energy-independent scattering approximation can be assumed [20], the Seebeck coefficient (S) can be given by the following equation:

where k B, h, m*, and n are Boltzmann constant, Planck constant, the effective mass of the carriers, and the carrier concentration, respectively. Equation (4) indicated the Seebeck coefficient mainly depended on carrier concentration. The main reason for the independence of the Seebeck coefficient on the surface modification of nanosized titania is that the carrier concentration not be affected by the surface modification of nanosized titania for it could not react with Nb-STO [10].

Conclusions

The liquid phase deposition approach was carried out to surface modify the Nb-doped SrTiO3 polycrystalline ceramics, and their thermoelectric performances were investigated. The surface modification of nanosized titania enhanced the ZT value significantly, because of the increased electrical conductivity, and obtained the highest ZT value of 0.33 at 900 K. Enhancement of the electrical conductivity was mainly caused by improved grain growth diminishing the number of the grain boundaries. Newly generated titanium carbide with higher electrical conductivity could also contribute the increased electrical conductivity. Pores homogeneously distributed in the Nb-STO composite could effectively scatter phonons, and hence, contributed to the reduction in the thermal conductivity of Nb-STO composite with the same relative density to pure Nb-STO composite. Seebeck coefficient was almost independent of nanosized titania addition, which was mainly due to the carrier concentration had not been affected by the surface modification of nanosized titania.

References

Dresselhaus MS, Chen G, Tang MY, Yang R, Lee H, Wang D, Ren Z, Fleurial JP, Gogna P (2007) New directions for low-dimensional thermoelectric materials. Adv Mater 19:1043–1053

Culebras M (2014) La1-xCaxMnO3 semiconducting nanostructures: morphology and thermoelectric performances. Nanoscale Res Lett 9(1):415

Tai G, Miao C, Wang Y, Bai Y, Zhang H (2011) Solvothermal synthesis and thermoelectric performances of indium telluride nanostring-cluster hierarchical structures. Nanoscale Res Lett 6:1–8

Hedden M, Francis N, Haraldsen JT, Ahmed T, Constantin C (2015) Thermoelectric performances of Nano-Meso-Micro β-MnO2 powders as a function of electrical resistanc. Nanoscale Res Lett 10:292

Kadel K, Kumari L, Wang X, Li W, Huang J, Provencio PP (2014) Synthesis and structure of undoped and indium-doped thermoelectric lead telluride nanoparticles. Nanoscale Res Lett 9:227

Tang X, Xie W, Li H, Zhao W, Zhang Q (2007) Preparation and thermoelectric transport performances of high-performance p- type Bi2Te3 with layered nanostructure. Appl Phys Lett 90:012102–012103

Mi JL, Zhao XB, Zhu TJ, Tu JP (2007) Improved thermoelectric figure of merit in n-type CoSb3 based nanocomposites. Appl Phys Lett 91:172116–3

Poudel B, Hao Q, Ma Y, Lan Y, Minnich A, Yu B, Yan X, Wang D, Muto A, Vashaee D, Chen X, Liu J, Dresselhaus MS, Chen G, Ren Z (2008) High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320:634–638

Li H, Tang X, Su X, Zhang Q (2008) Preparation and thermoelectric performances of high-performance Sb additional Yb0.2Co4Sb12 + y bulk materials with nanostructure. Appl Phys Lett 92:202114–3

Li H, Tang X, Zhang Q, Uher C (2009) High performance InxCeyCo4Sb12 thermoelectric materials with in-situ forming nanostructured InSb phase. Appl Phys Lett 94:102114–3

Kadel K, Kumari L, Li WZ, Huang JY, Provencio PP (2011) Synthesis and thermoelectric performances of Bi2Se3 nanostructures. Nanoscale Res Lett 6:1–7

Park K, Son JS, Woo SI, Shin K, Oh MW, Park SD, Hyeon T (2014) Colloidal synthesis and thermoelectric performances of La-doped SrTiO3 nanoparticles. J Mater Chem A 2:4217–4224

Zhang B, Wang J, Zou T, Zhang S, Yaer X, Ding N, Liu C, Miao L, Lia Y, Wu Y (2015) High thermoelectric performance of Nb-doped SrTiO3 bulk materials with different doping levels. J Mater Chem C 3:11406–11411

Wang N, He H, Li X, Han L, Zhang C (2010) Enhanced thermoelectric performances of Nb-doped SrTiO3 polycrystalline ceramic by titanate nanotube addition. J Alloys Compd 506:293–296

Wang N, Li H, Ba Y, Wang Y, Wan C, Fujinami K, Koumoto K (2010) Effects of YSZ additions on thermoelectric performances of Nb-doped strontium titanate. J Electron Mater 39:1777–1781

Wang N, Lin H, Li J, Zhang L, Lin C, Li X (2006) Crystalline transition from H2Ti3O7 nanotubes to anatase nanocrystallines under low-temperature hydrothermal conditions. J Am Ceram Soc 89:3564–3566

Katagiri K, Ohno K, Masuda Y, Koumoto K (2007) Growth behavior of TiO2 particles via the liquid phase deposition process. J Ceram Soc Jpn 15(1348):831–834

Klemens PG (1991) Thermal conductivity of inhomogeneous media. High Temp.-High Press, Oxford

Bäurer M, Kung H, Hoffmann MJ (2009) Influence of SrTi stoichiometry on the densification behavior of strontium titanate. J Am Ceram Soc 92:601–603

Cutler M, Leavy JF, Fitzpatrick RL (1964) Electronic transport in semimetallic cerium sulfide. Phys Rev 133:A1143–A1152

Acknowledgements

This work was financially supported by International Cooperation MOST-JST Program Fund (no. 2010DFA61410) and National Natural Science Foundation of China (no. 50802013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

EL carried out the fabircation of Nb-doped SrTiO3 ceramic and analysis of thermoelectric properties, and drafted the manuscript. NW participated in experimental design and the sequence alignment of manuscript. HH participated the SEM characterization. HC carried out the modifying Nb-STO particle by TiO2. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Li, E., Wang, N., He, H. et al. Improved Thermoelectric Performances of SrTiO3 Ceramic Doped with Nb by Surface Modification of Nanosized Titania. Nanoscale Res Lett 11, 188 (2016). https://doi.org/10.1186/s11671-016-1407-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1407-8