Abstract

Due to the good photocatalytic activity, the TiO2@CNTs thin film is highly desirable to apply to the self-cleaning glass for green intelligent building. Here, the TiO2@CNTs thin film has been successfully achieved by polymer-assisted approach of an aqueous chemical solution method. The polymer, polyethylenimine, aims to combine the Ti4+ with CNTs for film formation of TiO2@CNTs. The resultant thin film was uniform, highly transparent, and super-hydrophilic. Owing to fast electron transport and effectively hindering electron-hole recombination, the TiO2@CNTs thin film has nearly twofold photocatalytic performance than pure TiO2. The TiO2@CNTs thin films show a good application for self-cleaning glasses.

Similar content being viewed by others

Background

The serious environmental pollutions have attracted attention widely with the rapid growth of worldwide industry [1]. To tackle the pollution problem, photocatalysis has been demonstrated as a low-cost and sustainable technology for removing harmful organic contaminations in air and water. Since 1972 when Fujishima [2] discovered the photocatalytic activity on the titanium oxide (TiO2) photoanode in electrochemical cell under a UV-light, a great deal of semiconductor photocatalytic materials have been investigated [3, 4]. TiO2 has been a utility photocatalytic material owing to its low-cost, high oxidative efficiency, nontoxicity, and high chemical stability. However, the pure TiO2 has limited performance by easy recombination between the electrons and holes [5–8]. As it is well known, carbon nanotubes (CNTs) show good electron-accepting capability and fast electron transport [9–11]. Hoffmann proposed that TiO2@CNTs absorbed the energy and excited the electrons under illumination, and then, the electrons may transfer to CNTs while the holes may remain on TiO2 [12]. The electron and hole can be effectively separated by CNTs. Simultaneously, many research work have investigated the TiO2@CNTs system which indicated that the TiO2@CNT composite would be a promising candidate to enhance the photocatalytic performance [13–18]. Therefore, TiO2@CNTs is highly desirable to apply to the self-cleaning glass for green intelligent building. Usually, self-cleaning glass should require high photocatalytic activity, chemical stability, and super-hydrophilicity (super-hydrophobic) large area thin film [19, 20]. Up to now, Daeyeon Lee and coworkers fabricated the MWCNTs (multi-wall carbon nanotubes)/TiO2 thin films with significant enhancement photocatalytic performance through a layer-by-layer assembly method involving the MWCNTs incorporated TiO2 thin film [21]. Kim’s group prepared the CNT/TiO2 core/shell thin film and demonstrated the excellent performance [7] Oliveira’s group deposited the TiO2/MWCNTs coating with wettability and photocatalytic activity by sol-gel method [22]. Here, we design an approach to deposit TiO2@CNTs thin films with excellent photocatalytic performance for self-cleaning glass.

As well known, the surface of CNTs can be functionalized with hydrophilic groups (−COOH, −C = O, −OH) by acid oxidation [23, 24], and the hydrophilic group will react with the amine group of polyethylenimine (PEI) [25–27]. Meanwhile, Jia et al. reported that the Ti4+ could be combined with PEI to grow high-quality epitaxial TiO2 thin films [28, 29]. Inspired by these, we attempt to prepare Ti4+ combining PEI along with CNTs forming a stable and homogeneous precursor solution to fabricate TiO2@CNTs thin film. In general, most of work [22, 30] (such as O. Akhavan et al. and Dai et al.) reports sol-gel method, hydrolysis of titanium isopropoxide in CNTs solution, to deposit TiO2@CNTs thin film. Kwadwo E. Tettey group employed oppositely charged species of layer-by-layer (LbL) assembly approach to grow TiO2@CNTs thin film [21]. Muduli et al. utilized a hydrothermal method to prepare TiO2-MWCNTs composite [31]. Here, we provide a polymer-assisted deposition approach to grow TiO2@CNTs thin film. Polymer-assisted deposition approach has a key aqueous and homogenous system. The polymer can prevent ion hydrolysis in the solution, and the precursor could store in air stability for several months. The Ti ions and CNTs can be well distributed in precursor. The grown TiO2@CNT thin film shows the CNTs are homogenously embedded in the thin film. The viscosity and the concentration of the Ti4+ in precursor can be ready to tune the thickness of the thin films. This approach has the significant advantage over other methods, is a “bottom-up” method, and can form the conformal coating for complex structure. As a result, TiO2@CNTs thin film is readily grown with excellent photocatalytic activity. Both pure TiO2 thin film and TiO2@CNTs thin film have the high crystallinity and homogeneous surface. Owing to feasible design of carriers’ separation, the TiO2@CNTs thin films show better photocatalysis than the pure TiO2 thin films. It advances to deposit TiO2@CNTs in self-cleaning glasses by polymer-assisted approach.

Methods

Synthesis of CNTs-Ti4+ Precursor Solution

The Ti4+-PEI was prepared by an aqueous solution of Ti4+ ion bound to polymer. The solution containing 4 g of PEI and 4 g of ethylenediaminetetraacetic acid (EDTA) was stirred vigorously for a while until the PEI dissolved completely. Meanwhile, 2.5 g of TiCl4 was slowly added into a solution which included 5.0 g of 30 % H2O2 and 5 ml of water. Then, the TiCl4 solution was dropwise added to the PEI solution and maintained the pH of the PEI solution at about 7.5 by NH3·H2O until the mixture solution appears a precipitate. Finally, the solution was placed in an Amicon ultrafiltrations unit including an ultrafiltration membrane under 60-psi argon pressure. The Amicon ultrafiltration unit is designed to cut off <10,000 g/mol molecular weight while reserving the desired materials. The solution was diluted several times. The concentration of the final solution was 23.56 mg/ml which was conducted with inductively coupled plasma atomic emission spectroscopy (ICP-AES, PerkinElmer Optima 8000). CNTs grown by chemical vapor deposition (CVD) were purchased from Shenzhen Nanoport. Then, the CNTs was functionalized by refluxing in a mixture of concentrated nitric and sulfuric acids (1:3 in volume). The CNTs aqueous solution was added into Ti4+-precursor solution with stirring and vigorous ultrasonication for complete dispersion. We designed an experiment of thermal gravimetric analyzer (TGA) to characterize the final product (Additional file 1: Figure S1). The final product is matched with the ratios of the CNT added in the Ti4+ precursor at the beginning of the experiments. So, the ratio of CNTs in TiO2@CNT films is about 0, 2, 5, 8, and 10 %.

Preparation of TiO2@CNTs

For the TiO2@CNTs films, the final precursor was spin-coated on quartz at 2500 rpm for 30 s, then the film was calcinated at 400 °C for 2 h in air. Similarly, a reference experiment in the absence of CNTs was prepared.

Characterization

Ti4+ concentration in precursor solution was measured by inductively coupled plasma atomic emission spectrometer (ICP-AES, PerkinElmer Optima 8000). X-ray diffraction (XRD) measurement was taken on a Riguku D/MAX-2000PC diffraction system to evaluate the crystal structure. Raman shift spectroscopy was recorded using HR800 (Raman HORIBA Jobin Yvon) with a 514-nm excitation wavelength. Scanning electron microscopy (SEM) images were observed on SU8010 (HITACHI) systems. The ultraviolet-visible (UV-VIS) spectrum was tested by using Shimadzu UV-2450. The water contact angle of the film surfaces was carried on contact angle measurement (Data Physics OCA). The electrochemical impedance spectra were tested by electrochemical workstation.

Photocatalytic Experiments

Methyl orange (MO) dye was used to study the photocatalytic activity of the samples under a UV-light irradiation (5 W). The concentration of the MO dye aqueous solution is 10 mg/L. The TiO2 thin films and TiO2@CNTs thin films were fastened by cotton and immersed in the MO (10 mg/L) aqueous solution, respectively. Before illumination, the MO dye aqueous solution was stirred for 1 h under dark for adsorption-desorption equilibrium. After that, the MO dye solution was irradiated under a UV-light. At a 20-min interval, the solution was analyzed by recording the UV-spectrum of MO dye aqueous solution.

Results and Discussion

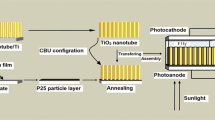

Scheme 1 depicts the preparation process of TiO2@CNTs thin film. The PEI combines to Ti4+ complex by static electricity forming the PEI-Ti4+ precursor solution and the functional CNTs bind with the amino group of PEI. Here, PEI acts as a “bridge” to link Ti4+ complex and CNTs to form the Ti4+ complex-CNTs precursor. Simultaneously, PEI can control the viscosity of the precursor solution to help film formation by spin-coating process.

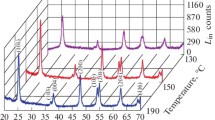

The products are analyzed by X-ray diffraction (XRD) measurement. As shown in Fig. 1a, there are two black peaks at 26.2° and 42.8° corresponding to (002) and (100) diffractions of CNTs. The peaks of XRD blue pattern at 25.38°, 37.94°, 48.3°, 54.04°, 55.16°, 62.72°, 68.9°, 70.38°, and 75.16° are indexing to (101), (004), (200), (105), (211), (204), (116), (220), and (215), which confirms to anatase TiO2 (JCPDS card No.21-1272). There are no any other peaks which indicate that the pure anatase TiO2 sample has been obtained. In the XRD red pattern, there is no obvious CNTs diffraction peak seen in TiO2@CNT thin film because of strong background and diffraction peak (101) overlap of TiO2 [32]. Raman microscopy shown in Fig. 1b is used to further analyze CNTs, TiO2, and TiO2@CNTs. The characteristic bands of black peaks at 1331 and 1595 cm−1 are indexing to D band and G band of CNTs. The blue peaks at 147, 397, 522, and 640 cm−1 are corresponding to Eg, B1g, B1g, and Eg active modes of anatase TiO2. Seen from the red peaks of Raman spectra, there were not only the characteristic bands of anatase TiO2 but also the D band and G band of CNTs, confirming the presence of both anatase TiO2 and CNTs in the final of product TiO2@CNTs composite [33].

Self-cleaning performance of TiO2@CNTs thin films is achieved by super-hydrophilicity and good photocatalytic activity. The surface morphologies of the pure TiO2 film and TiO2@CNTs thin film are investigated by using a scanning electron microscope (SEM) as shown in Fig. 2a, b). The SEM images show that the thin films are homogeneously covered on the substrates. Seen from the TiO2@CNTs thin films, most of CNTs are embedded in TiO2 thin film and only few CNT is bared on the surface of the thin film. The cross-sectional images of pure TiO2 thin film and TiO2@CNTs thin film (Fig. 2c, d) show a clear interface between the substrate and the thin film, and the thickness of the thin films is about 500 nm. Meanwhile, the pure TiO2 thin film is stacked by nanoparticle while the TiO2@CNTs thin film is composed of nanoparticles along with the CNTs. The water contact angle is measured to analyze the wettability of the films. The contact angles of the pure TiO2 films and TiO2@CNTs thin film are 7.2° and 3.6° in Fig. 2e, f, respectively. Compared with the glass’s 40.7° (Additional file 1: Figure S3), both the TiO2 and TiO2@CNTs thin films’ contact angles are hydrophilic (<10°). The TiO2@CNTs thin films show super-hydrophilicity (<5°). Super-hydrophilic TiO2@CNTs thin film, preventing water condensation on a substrate, is of great importance for self-cleaning applications. It is noted that transmission of the thin films is another advanced property to self-cleaning glass. Additional file 1: Figure S2 illustrates the transparency of quartz, TiO2 thin film on quartz substrate, and TiO2@CNT thin film on quartz substrate. Although the TiO2@CNT thin film shows lower transparency than the TiO2 thin film, both of them have good transmittance.

SEM images of as-prepared pure TiO2 thin film (a) and TiO2@CNTs thin film (The CNTs are labelled by ellipse, typically.) (b); the cross-sectional images of as-prepared pure TiO2 thin film (c) and TiO2@CNTs thin film (d); the images of water contact angle test for pure TiO2 thin film (e) and TiO2@CNTs thin film (f)

The photocatalytic activities of TiO2@CNTs thin film and pure TiO2 thin film are evaluated by methyl orange (MO) dye degradation under UV-light irradiation after stirring in the dark for adsorption-desorption equilibrium. The photocatalysis performance about different content CNTs in TiO2@CNTs thin film is shown in Additional file 1: Figure S4. The results show that the TiO2@CNTs thin film with 5 % CNTs has the best performance. For comparison, the photocatalytic performance of the pure TiO2 thin film and TiO2@CNTs (5 %) thin film is detailedly analyzed as follows. The absorption spectra of the MO dye aqueous solution are shown in Fig. 3a, b with increasing UV-light irradiation time. The absorption peak at 465 nm is the intrinsic absorption of MO dye. The absorption peaks of MO dye are decreased upon time with TiO2@CNTs composite catalyst and pure TiO2 catalyst. The absorption peak diminishes completely after 80 min for the TiO2@CNTs thin film. However, as for the pure TiO2, the absorption peak decreases slowly, and the absorption peak of dyes does not disappear even after 180 min. The gradual decrease in the absorption of the MO dye is attributed to the decomposition of MO dye [34, 35]. The degradation of MO dye is carried out by hydroxyl radicals which are generated by transferring electrons and holes from photocatalytic materials to the dye aqueous solution. In Fig. 3c, the normalized temporal concentration changes (C/C 0) of MO dye aqueous solution can also illustrate the photocatalytic performance during the degradation (C 0 is the initial concentration of MO dye and C is the concentration of MO dye with different reaction time). After 80-min UV-light irradiation, over 93 % and ~55 % of the initial dyes are decomposed by TiO2@CNTs composite and pure TiO2, respectively. The photocatalytic efficiency of TiO2@CNTs thin films is nearly twofold that of TiO2 thin film. Therefore, the results demonstrate that the photocatalytic performance was greatly enhanced by the TiO2@CNTs thin film. The performance is comparable to the others in the literature [5, 7]. Meanwhile, the TiO2@CNTs thin films show good stability and recyclability in Additional file 1: Figure S5.

The photoelectric properties of pure TiO2 and TiO2@CNTs help to analyze the enhanced photocatalysis of TiO2@CNTs. The electrochemical impedance spectra can effectively illustrate the electron transport between the electrode and electrolyte interfaces. The equivalent electrical circuit mode can be drawn from Nyquist plot. The semicircle is attributable to the total charge transfer resistance (Rcf) and the capacitance of the space charge region (C) including charge transfer across the FTO/TiO2@CNTs interface and TiO2@CNTs/electrolyte interface [36, 37]. For TiO2@CNTs, Rcf and C are 53.1 Ω and 4.83 × 10−7 f, respectively. While for pure TiO2, Rcf and C are 320 Ω and 35.4 × 10−6 f, respectively. Based on the Nyquist plots (Fig. 4a), it shows a decrease in the interface layer resistance and charge transfer resistance on the TiO2@CNTs surface. The smaller radius of the arc in Nyquist plots means smaller resistance and faster electron transportation [38, 39]. In addition, the charge transfer mechanism between the TiO2 and CNTs during the photocatalysis is shown in Fig. 4b and the energy band diagram of TiO2/CNTs structure is shown in Fig. 4(c). Under the illumination, the electron (e−) of TiO2 are excited to the conductor band while the holes (h+) are left to the valence band for oxidation of MO dye. Meanwhile, the hole can adsorb the OH− in the water and generates the OH ., and the electron can react with the O2 to form the O2 −. The O2 − and OH. show strong degradation of dye. Furthermore, owing to the low Fermi level of CNTs, the electrons are easily injected to CNTs. Another important role of CNTs in the C composite is being a fast electron transporter due to its one-dimensional structure. As a result, the electron-accepting and electron-transporting properties of CNTs in TiO2@CNTs composite can effectively hinder electron-hole pair recombination and leave more holes to promote the degradation of MO dyes. This phenomenon has been demonstrated by a large number of previous dye degradation [15, 40, 41]. TiO2@CNTs thin films have high-quality, super-hydrophilic surface and good photocatalytic performance to stimulate its application in the fields of self-cleaning glass.

Conclusions

In summary, we developed a polymer-assisted approach to synthesize the anatase TiO2@CNTs thin films. The polymer not only urges TiO2 and CNTs combination but also facilitates TiO2@CNTs film formation. The resultant TiO2@CNTs films are compact and present good transmission and super-hydrophilicity. Due to advancing fast electron transport and effectively hindering electron-hole pair recombination, TiO2@CNTs thin film performs the photocatalytic efficiency with nearly twofold to pure TiO2. The aqueous and feasible technology of thin film fabrication brings TiO2@CNT thin film to be a good candidate for self-cleaning glasses.

Abbreviations

- CNTs:

-

Carbon nanotubes

- ICP-AES:

-

Inductively coupled plasma atomic emission spectrometer

- MO:

-

Methyl orange

- SEM:

-

Scanning electron microscope

- TiO2 :

-

Titanium oxide

- XRD:

-

X-ray diffraction

References

Wang Y, Wang Q, Zhan X, Wang F, Safdar M, He J (2013) Visible light driven type II heterostructures and their enhanced photocatalysis properties: a review. Nanoscale 5:8326–8339

Fujishima A (1972) Electrochemical photolysis of water at a semiconductor electrode. Nature 238:37–38

Guo HL, Zhu Q, Wu XL, Jiang YF, Xie X, Xu AW (2015) Oxygen deficient ZnO1-x nanosheets with high visible light photocatalytic activity. Nanoscale 7:7216–7223

Han C, Chen Z, Zhang N, Colmenares JC, Xu YJ (2015) Hierarchically CdS decorated 1D ZnO nanorods-2D graphene hybrids: low temperature synthesis and enhanced photocatalytic performance. Adv Funct Mater 25:221–229

Xu YJ, Zhuang Y, Fu X (2010) New insight for enhanced photocatalytic activity of TiO2 by doping carbon nanotubes: a case study on degradation of benzene and methyl orange. J Phys Chem C 114:2669–2676

Xiang Q, Yu J, Jaroniec M (2012) Synergetic effect of MoS2 and graphene as cocatalysts for enhanced photocatalytic H2 production activity of TiO2 nanoparticles. J Am Chem Soc 134:6575–6578

Lee WJ, Lee JM, Kochuveedu ST, Han TH, Jeong HY, Park M, Yun JM, Kwon J, No K, Kim DH, Kim SO (2012) Biomineralized N-doped CNT/TiO2 core/shell nanowires for visible light photocatalysis. ACS Nano 6:935–943

Anandan S, Rao TN, Sathish M, Rangappa D, Honma I, Miyauchi M (2013) Superhydrophilic graphene-loaded TiO2 thin film for self-cleaning applications. ACS Appl Mater Interfaces 5:207–212

Avouris P, Chen Z, Perebeinos V (2007) Carbon-based electronics. Nat nanotechnology 2:605–615

Lee JM, Kwon BH, Park HI, Kim H, Kim MG, Park JS, Kim ES, Yoo S, Jeon DY, Kim SO (2013) Exciton dissociation and charge-transport enhancement in organic solar cells with quantum-dot/N-doped CNT hybrid nanomaterials. Adv Mater 25:2011–2017

Li GR, Wang F, Jiang QW, Gao XP, Shen PW (2010) Carbon nanotubes with titanium nitride as a low-cost counter-electrode material for dye-sensitized solar cells. Angew Chem Int Ed Engl 49:3653–3656

Hoffmann MR, Martin ST, Choi WY, Bahnemann DW (1995) Environmental applications of semiconductor photocatalysis. Chem Rev 95:69–96

Liu Z, Han B (2009) Synthesis of carbon-nanotube composites using supercritical fluids and their potential applications. Adv Mater 21:825–829

Zhao Y, Hu Y, Li Y, Zhang H, Zhang S, Qu L, Shi G, Dai L (2010) Super-long aligned TiO2/carbon nanotube arrays. Nanotechnology 21:505702

Woan K, Pyrgiotakis G, Sigmund W (2009) Photocatalytic carbon-nanotube-TiO2 composites. Adv Mater 21:2233–2239

Lee SW, Sigmund WM (2003) Formation of anatase TiO2 nanoparticles on carbon nanotubes. Chem Comm 6:780–781

Yang MQ, Zhang N, Xu YJ (2013) Synthesis of fullerene, carbon nanotube, and graphene-TiO2 nanocomposite photocatalysts for selective oxidation: a comparative study. ACS Appl Mater Interfaces 5:1156–1164

Yu J, Ma T, Liu S (2011) Enhanced photocatalytic activity of mesoporous TiO2 aggregates by embedding carbon nanotubes as electron-transfer channel. Phys Chem Chem Phys 13:3491–3501

Furstner R, Barthlott W, Neinhuis C, Walzel P (2005) Wetting and self-cleaning properties of artificial superhydrophobic surfaces. Langmuir 21:956–961

Gan WY, Lam SW, Chiang K, Amal R, Zhao H, Brungs MP (2007) Novel TiO2 thin film with non-UV activated superwetting and antifogging behaviours. J Mater Chem 17:952

Tettey KE, Yee MQ, Lee D (2010) Photocatalytic and conductive MWCNT/TiO2 nanocomposite thin films. ACS Appl Mater Interfaces 2:2646–2652

Castro MR, Sam ED, Veith M, Oliveira PW (2008) Structure, wettability and photocatalytic activity of CO2 laser sintered TiO2/multi-walled carbon nanotube coatings. Nanotechnology 19:105704

Kabbani MA, Tiwary CS, Autreto PA, Brunetto G, Som A, Krishnadas KR, Ozden S, Hackenberg KP, Gong Y, Galvao DS, Vajtai R, Kabbani AT, Pradeep T, Ajayan PM (2015) Ambient solid-state mechano-chemical reactions between functionalized carbon nanotubes. Nat Commun 6:7291

Gao G, Pan M, Vecitis CD (2015) Effect of the oxidation approach on carbon nanotube surface functional groups and electrooxidative filtration performance. J Mater Chem A 3:7575–7582

Bourlinos AB, Georgakilas V, Tzitzios V, Boukos N, Herrera R, Giannelis EP (2006) Functionalized carbon nanotubes: synthesis of meltable and amphiphilic derivatives. Small 2:1188–1191

Rodriguez AJ, Guzman ME, Lim CS, Minaie B (2010) Synthesis of multiscale reinforcement fabric by electrophoretic deposition of amine-functionalized carbon nanofibers onto carbon fiber layers. Carbon 48:3256–3259

Lei Y, Xiong C, Dong L, Guo H, Su X, Yao J, You Y, Tian D, Shang X (2007) Ionic liquid of ultralong carbon nanotubes. Small 3:1889–1893

Jia QX, McCleskey TM, Burrell AK, Lin Y, Collis GE, Wang H, Li AD, Foltyn SR (2004) Polymer-assisted deposition of metal-oxide films. Nat Mater 3:529–532

Zou GF, Zhao J, Luo HM, McCleskey TM, Burrell AK, Jia QX (2013) Polymer-assisted-deposition: a chemical solution route for a wide range of materials. Chem Soc Rev 42:439–449

Dai K, Peng T, Ke D, Wei B (2009) Photocatalytic hydrogen generation using a nanocomposite of multi-walled carbon nanotubes and TiO2 nanoparticles under visible light irradiation. Nanotechnology 20:125603–125608

Muduli S, Lee W, Dhas V, Mujawar S, Dubey M, Vijayamohanan K, Han SH, Ogale S (2009) Enhanced conversion efficiency in dye-sensitized solar cells based on hydrothermally synthesized TiO2-MWCNT nanocomposites. ACS Appl Mater Interface 9:2030–2035

Fan W, Lai Q, Zhang Q, Wang Y (2011) Nanocomposites of TiO2 and reduced graphene oxide as efficient photocatalysts for hydrogen evolution. J Phys Chem C 115:10694–10701

Hemalatha K, Prakash ASKG, Jayakumar M (2014) TiO2 coated carbon nanotubes for electrochemical energy storage. J Mater Chem A 2:1757–1766

Han L, Wang P, Zhu C, Zhai Y, Dong S (2011) Facile solvothermal synthesis of cube-like Ag@AgCl: a highly efficient visible light photocatalyst. Nanoscale 3:2931–2935

Burda C, Lou Y, Chen X, Samia ACS, Stout J, Gole JL (2003) Enhanced nitrogen doping in TiO2 nanoparticles. Nano Lett 3:1049–1051

Xu C, Song Y, Lu L, Cheng C, Liu D, Fang X, Chen X, Zhu X, Li D (2013) Electrochemically hydrogenated TiO2 nanotubes with improved photoelectrochemical water splitting performance. Nanoscale Res Lett 8:391–397

Chang WC, Cheng YY, Yu WC, Yao YC, Lee CH, Ko HH (2012) Enhancing performance of ZnO dye-sensitized solar cells by incorporation of multiwalled carbon nanotubes. Nanoscale Res Lett 7:166–172

Zhu A, Zhao Q, Li X, Shi Y (2014) BiFeO3/TiO2 nanotube arrays composite electrode: construction, characterization, and enhanced photoelectrochemical properties. ACS Appl Mater Interfaces 6:671–679

Zhang H, Lv X, Li Y, Wang Y, Li J (2010) P25-graphene composite as a high performance photocatalyst. ACS Nano 4:380–386

Akhavan O, Azimirad R, Safa S, Larijani MM (2010) Visible light photo-induced antibacterial activity of CNT–doped TiO2 thin films with various CNT contents. J Mater Chem 20:7386–7392

Yan W, He F, Gai S, Gao P, Chen Y, Yang P (2014) A novel 3D structured reduced graphene oxide/TiO2 composite: synthesis and photocatalytic performance. J Mater Chem A 2:360

Acknowledgements

We gratefully acknowledge the support from “973 Program—the National Basic Research Program of China” Special Funds for the Chief Young Scientist (2015CB358600), the Excellent Young Scholar Fund from the National Natural Science Foundation of China (21422103), Jiangsu Fund for Distinguished Young Scientist (BK20140010), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), and Jiangsu Scientific and Technological Innovation Team (2013).

Authors’ Contributions

QY carried out all the measurement and drafted the manuscript. HW tested the photocatalytic performance. SC and YC carried out the SEM test. YW helped to test the EIS curve. YS, YL, and JZ participated in the discussion of the study. JW participated in the discussion of the study and helped to write the manuscript. GZ conceived of the study and participated in its design. All authors read and approved the final manuscript.

Competing Interests

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Additional file

Additional file 1:

Supporting information. (DOCX 860 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Yi, Q., Wang, H., Cong, S. et al. Self-Cleaning Glass of Photocatalytic Anatase TiO2@Carbon Nanotubes Thin Film by Polymer-Assisted Approach. Nanoscale Res Lett 11, 457 (2016). https://doi.org/10.1186/s11671-016-1674-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1674-4