Abstract

In the present paper, we show tungsten diselenide (WSe2) devices that can be tuned to operate as n-type and p-type field-effect transistors (FETs) as well as band-to-band tunnel transistors on the same flake. Source, channel, and drain areas of the WSe2 flake are adjusted, using buried triple-gate substrates with three independently controllable gates. The device characteristics found in the tunnel transistor configuration are determined by the particular geometry of the buried triple-gate structure, consistent with a simple estimation of the expected off-state behavior.

Similar content being viewed by others

Background

In recent years, two-dimensional layered materials, such as graphene and transition metal dichalcogenides (TMDs), have attracted a great deal of interest as channel material in high-performance field-effect transistors (FETs) [1–8]. A major advantage of these materials is their ability to drive high electrical currents in only few layers or even a monolayer (<1 nm). In addition, there are a number of semiconducting TMDs that exhibit band gaps ≥ 1 eV. Thus, they are in principle ideally suited for ultimately scaled FETs as well as for band-to-band tunnel FETs tunnel field-effect transistors (TFETs) since the ultrathin channel layer enables excellent gate control yielding ultimate scalability and a large band-to-band tunnel probability [9–16].

However, a major challenge for the application of TMDs is the realization of an appropriate source-channel-drain doping profile because conventional (e.g., impurity, chemical) doping is extremely challenging [17, 18], and in the case of TFETs, the right amount of doping is subject to tedious optimization: if the doping concentration is too small, the gate action is not sufficiently screened, and the band-to-band tunneling probability cannot be made large enough. On the other hand, a large doping concentration may lead to a large Fermi energy, and as a result, carriers are injected from the Boltzmann tail of the source Fermi distribution function giving rise to a TFET with an inverse subthreshold slope close to 60 mV/dec [19–21]. A viable alternative is source-drain doping by means of electrostatic potentials, which has already been employed to investigate carbon nanotube, graphene, and nanowire FETs as well as optoelectronic devices [9, 22–28]. This approach not only allows convenient doping, but in a TFET, it enables to disentangle screening in source from the position of the Fermi energy [21]. Moreover, electrostatic doping adds device level functionality through the tunability to operate the same device in various transistor configurations. Specifically, if the electrostatic doping is controllable individually for source and drain, not only the n-type and p-type FETs can be realized [29] but the device can also be switched into a TFET mode of operation which allows tuning to devices from conventional to low-power operation.

Here, we present a tungsten diselenide (WSe2) device which we tune by electrostatic doping to function as an nFET (n-n doping profile), pFET (p-p doping profile), and TFET (n-p doping profile). WSe2 is used here since, in contrast to molybdenum disulfide (MoS2), it provides an approximately mid-gape Fermi level line-up for (e.g., nickel) ensuring that electrons as well as holes can be injected efficiently in the different device configurations [30]. In addition, it exhibits a smaller band gap and lower effective masses compared to MoS2, both known to improve the performance of TFETs [13–16, 21]. The electrostatic doping is realized by a modified version of our previously employed buried triple-gate (BTG) structure [31]. This structure features three independently controllable gates: one center-gate and two side-gates for electrostatic doping. Since all three gates are buried and the BTG’s surface is entirely flat, the structure serves as a platform for convenient deposition and investigation of devices from various kinds of novel channel materials. The electrostatic environment is fully determined by the BTG structure, therefore, allows true comparison of various materials in terms of their suitability for future FET or TFET devices.

Methods

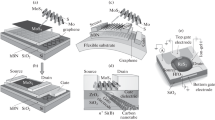

Figure 1 illustrates the manufacturing process of the BTG structure. The starting material is a 4′′ silicon-on-insulator (SOI) wafer with a top layer of 340 nm (100) Si and a 400 nm buried oxide (BOX). The silicon is implanted with 1015 cm−2 of phosphorous at 75 keV, 7.5°, yielding a peak implantation depth of 104 nm. Afterwards, the wafer is RCA-cleaned, and a 200-nm layer of Si3N4 is deposited by a plasma-enhanced chemical vapor deposition. Subsequently, a furnace treatment at 900 °C for 20 min heals the implantation damage, activates the dopants, and condenses the nitride. Optical lithography in combination with CHF3 + O2 plasma etching is used to pattern the nitride layer. After the removal of the photoresist (PR) and directly after an additional buffered oxide etch dip, tetramethylammonium hydroxide (TMAH), 25 wt% at 80 °C, is used to anisotropically etch through the SOI top layer (cf. Fig. 1a). Wet thermal oxidation is used to grow the gate-side-gate (G-SG) insulation (Fig. 1b). Afterwards, the nitride mask is removed by a two-step procedure: (i) CHF3 + O2 plasma removes the oxidized nitride and (ii) H3PO4 at 160 °C removes the remaining nitride. No apparent oxidation under the nitride mask (bird’s beak) is present. A thin oxide (~10 nm) is grown on the silicon surface in order to serve as an additional insulation and as a stopping layer for the following damascene process: After sputter-deposition of aluminum onto the surface, chemical–mechanical planarization (CMP) is employed to remove the Al overburden yielding an entirely planar structure (Fig. 1c). To reduce the thermally induced growth of hillocks on the Al-surface, a repolishing procedure is used [32]. The gate dielectric is obtained by atomic layer deposition (ALD) of 7 nm Al2O3 (Fig. 1d). The BTG structures are completed by selectively etching the oxides using CHF3 + Ar plasma in the contact regions and subsequent deposition of 10 nm Ti + 170 nm Au as side and top-gate contact metals using a lift-off technique. The finished wafer is cut into sample pieces of 7.5 × 7.5 mm2; Fig. 1e shows a schematic device cross-section and bird’s-eye view.

Figure 1f presents a scanning electron microscopy (SEM) micrograph of the BTG’s surface and cross-section. Clearly visible is the G-SG insulation of 90 nm. Not visible is the 7 nm Al2O3 dielectric cap layer on the surface. An excellent topography, with a dishing of only ~1 nm per micron, and quality (only few pits and scratches, roughness down to 1-nm root mean square) of the polished aluminum is achieved [32, 33].

For the fabrication of the WSe2 devices on the BTG structure, first, WSe2 is exfoliated from bulk material using a blue tack tape. Figure 2a shows a section of a BTG meander with additional electron-beam lithography markers. The sample is inspected using optical microscopy in order to identify thin flakes (<10 nm) lying across the aluminum gate, e.g., a flake as in location (I.). Thin flakes were found to exhibit a characteristic yellowish color on the gate region (Al2O3/Al) with a strong contrast to thicker flakes of ~15–25 nm, which appear distinctly blue-colored (cf. locations (II.) and (III.)). Interestingly, such a clear distinction is not present on the side-gate region (Al2O3/SiO2/Si/SiO2/Si). The characteristic swing from blue to yellowish colors identifying the thinnest flakes is also confirmed by our simulations, as shown in Fig. 2b [34].

After identification of appropriate flakes, electron-beam lithography is used to pattern source/drain contact structures into polymethyl methacrylate (PMMA). Subsequently, deposition of 90 nm nickel and lift-off are employed to obtain the contact structures and complete the devices. Figure 2c depicts the flake from (a) after contact formation. In order to determine the thickness of the flakes, atomic force microscopy (AFM) is conducted. Figure 2d shows the AFM surface profile of the presented flake, indicating a thickness of ~6–8 nm.

Results and Discussion

Figure 3 illustrates the operational principle of our devices: For the realization of an nFET (Fig. 3b), positive and equal voltage is applied to both side-gates (this means that V SSG = V DSG > 0. For simplicity, this will be called side-gate voltage V SG in the following) which lowers the bands in the regions controlled by the side-gates (SSG and DSG) and yields an n-n doping profile. Note that all given voltages are in reference to the ground potential at the source contact. The described electrostatic doping yields a thinning of the source and drain Schottky barriers (SB) for electron injection while suppressing hole injection at the same time. As a result, a unipolar device behavior is expected in contrast to the usually observed ambipolar behavior of WSe2 transistors. Applying positive voltage to the center gate, i.e., the actual gate of the device (denoted with V G in the following), yields a lowering of the bands in the gate-controlled region (G) and switches the device on. The described mechanism can be employed similarly to realize a pFET device (i.e., a p-p doping profile) by applying V SG < 0, V G < 0 (cf. Fig. 3d). Figure 4 displays transfer characteristics of a WSe2 with a thickness of d WSe2 = 3 nm determined by AFM. The source-drain bias (V DS) is constant at 1 V and the various curves presented are from different side-gate voltages. The n-doping (Fig. 4a) leads to an increase of the drain current up to an I on/I off ratio of >3 × 105 at V SG = 4 V. As already mentioned above, a pFET device is realized for V SG < 0, V G < 0. In this case, we find an I on/I off ratio of ~103 at V SG = −4 V (cf. Fig. 4b). The ~100× larger n-current in comparison to the p-current (as well as the larger leakage current on the pFET compared to the nFET) is attributed to the influence of the nickel contacts, which were shown to be slightly more n-type [7, 30]. The subthreshold swings are 180 mV/dec (nFET) and 240 mV/dec (pFET), respectively. Note, that the current for large positive (n-type device) and negative (p-type device) gate voltages V G saturates, and current flow is then limited by the injection through the source-side SB. Since the tunneling probability is a function of the barrier height (0.54 and 0.74 eV in the case of electron and hole injection, respectively) and effective mass (0.34 and 0.44 m0 for electrons and holes, respectively), a different modulation of the tunneling probability through the SB is obtained for the n-type and the p-type [30]. As a result, the side-gates have considerably less impact on the SB in the p-type device which is reflected in the drain current for abs(V SG) > 2 V that hardly changes anymore.

Schematic band diagrams for electrostatically doped nFET, pFET, and TFET devices. a Illustration in the case of zero gate voltage in source, drain, and gate area. b Positive side-gate voltages create n-type regions in source and drain, c a positive side-gate voltage in source and a negative side-gate voltage in drain yield a tunnel FET device. d In the case of negative side-gate voltages, p-type source/drain electrodes are realized

In addition, for this device we are also able to set up a TFET device configuration with an n-type source and a p-type drain contact using V DS = −500 mV, V SSG = 4 V, V DSG <−4 V. As displayed in Fig. 4c, the gate leakage current in the TFET device configuration is at least 30× lower than the drain current. It is important to note that usually temperature-dependent measurements of the off-state are used to demonstrate TFET behavior. However, in the present case, we were able to demonstrate n- and p-type device behavior proving that a conduction-/valence-band profile appropriate for TFETs can be adjusted using the BTG. And since gate leakage can be neglected, we ascribe the exponential increase of current around V G = 0 V to band-to-band tunneling. This is also consistent with the fact that increasingly negative DSG voltages improve the band-to-band tunneling probability (by increasing the electric field at the G/DSG junction) while at the same time hinder thermionic transport due to an increased potential barrier carriers from drain have to overcome.

The I on/I off ratio is ~4.5 × 102 at V DSG = −6 V, and the inverse subthreshold slope is S ≈ 366 mV/dec. This rather large value is due to the fact that overpolishing during the CMP fabrication process leads to a G-SG insulation of approximately d G-SG = 90 nm (cf. Fig. 1f). Interpreting the band-to-band tunneling barrier as a SB, the expected inverse subthreshold slope can be computed with \( S\approx {k}_BT/q\cdot ln(10)\;\left(1/2+1/3\cdot \sqrt{d_{\mathrm{G}\hbox{-} \mathrm{S}\mathrm{G}}{d}_{\mathrm{WSe}2}}\right) \) [35, 36] yielding S ≈ 358 mV/dec. This agrees very well with the experimental value showing that it is the G-SG insulation that limits the performance of the device with n-p doping. Further improvements in the BTG fabrication will therefore allow a substantial performance increase. In addition, the channel layer thickness, i.e., the WSe2 flake thickness, plays a prominent role for the device performance of the TFETs [15, 16]. Indeed, in the case of a device with an approximately 13-nm-thick WSe2 flake, we found a strongly deteriorated TFET behavior (not shown here). In turn, a thinner flake should allow substantial improvements in terms of inverse subthreshold slope and on-state current in the TFET configuration.

From the mere consideration of the band gap of WSe2, we would expect a larger on/off current ratio with significantly smaller off-state currents. However, an explanation of this phenomenon requires a detailed simulation of the device structure including the fact that in the present device, the distribution of the injected current among the various WSe2 layers [37] depends on the different (side-) gate voltages. We therefore speculate that band-to-band tunneling as well as interlayer coupling is responsible for the electrical behavior of the device in TFET configuration.

Conclusions

We demonstrated that electrostatic doping allows the realization of a tunable device to function as nFET, pFET, and as band-to-band tunnel FET on the same WSe2 flake. Based on a BTG substrate, we were able to dope source and drain regions independently to create the required band-profiles for the three transistor configurations. An optimized triple-gate configuration thus enables to dynamically switch transistors from conventional (nFET, pFET) to low-power (TFET) operation.

References

Jena D (2013) Tunneling transistors based on graphene and 2-D crystals. Proc IEEE 101:1585–1602

Fiori G, Bonaccorso F, Iannaccone G, Palacios T, Neumaier D, Seabaugh A, Banerjee S, Colombo L (2014) Electronics based on two-dimensional materials. Nat Nanotechnol 9:768–779

Sik Hwang W, Remskar M, Yan R, Protasenko V, Tahy K, Doo Chae S, Zhao P, Konar A, Xing HG, Seabaugh A, Jena D (2012) Transistors with chemically synthesized layered semiconductor WS2 exhibiting 105 room temperature modulation and ambipolar behavior. Appl Phys Lett 101:013107-1–3

Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A (2011) Single-layer MoS2 transistors. Nat Nanotechnol 6:147–150

Fathipour S, Remskar M, Varlec A, Ajoy A, Yan R, Vishwanath S, Rouvimov S, Hwang WS, Xing HG, Jena D, Seabaugh A (2015) Synthesized multiwall MoS2 nanotube and nanoribbon field-effect transistors. Appl Phys Lett 106:022114 1–3

Fathipour S, Ma N, Hwang WS, Protasenko V, Vishwanath S, Xing HG, Xu H, Jena D, Appenzeller J, Seabaugh A (2014) Exfoliated multilayer MoTe2 field-effect transistors. Appl Phys Lett 105:192101-1–3

Das S, Appenzeller J (2013) WSe2 field effect transistors with enhanced ambipolar characteristics. Appl Phys Lett 103:103501-1–3

Fathipour S, Hwang WS, Kosel T, Xing HG, Haensch W, Jena D, Seabaugh A (2013) Exfoliated MoTe2 field-effect transistor. Dev Res Conf (DRC) 71:115–116

Appenzeller J, Lin Y-M, Knoch J, Avouris P (2004) Band-to-band tunneling in carbon nanotube field-effect transistors. Phys Rev Lett 93:196805-1-4

Bhuwalka KK, Born M, Schindler M, Schmidt M, Sulima T, Eisele I (2006) P-channel tunnel field-effect transistors down to sub-50 nm channel lengths. J J Appl Phys 45:3106

Boucart K, Ionescu AM (2007) Double-gate tunnel FET with high-k gate dielectric. IEEE Trans Electron Dev 54:1725–1733

Knoll L, Schmidt M, Zhao Q, Trellenkamp S, Schaefer A, Bourdelle K, Mantl S (2013) Si tunneling transistors with high on-currents and slopes of 50 mV/dec using segregation doped NiSi2 tunnel junctions. Solid-State Electron 84:211–215

Ionescu A, Riel H (2011) Tunnel field-effect transistors as energy-efficient electronic switches. Nature 479:329–337

Seabaugh AC, Zhang Q (2010) Low-voltage tunnel transistors for beyond CMOS logic. Proc IEEE 98:2095–2110

Sandow C, Knoch J, Urban C, Zhao Q-T, Mantl S (2009) Impact of electrostatics and doping concentration on the performance of silicon tunnel field-effect transistors. Solid-State Electron 53:1126–1129

Knoch J (2009) Optimizing tunnel FET performance—impact of device structure, transistor dimensions and choice of material. Internat. Symp. VLSI Technol., Syst. Appl VLSI-TSA. 45–46

Gong Y, Liu Z, Lupini AR, Shi G, Lin J, Najmaei S, Lin Z, Elias AL, Berkdemir A, You G, Terrones H, Terrones M, Vajtai R, Pantelides ST, Pennycook SJ, Lou J, Zhou W, Ajayan PM (2014) Band gap engineering and layer-by-layer mapping of selenium-doped molybdenum disulfide. Nano Lett 14:442–449

Kiriya D, Tosun M, Zhao P, Kang JS, Javey A (2014) Air-stable surface charge transfer doping of MoS2 by benzyl viologen. J Am Chem Soc 136:7853–7856

Knoch J, Mantl S, Appenzeller J (2007) Impact of the dimensionality on the performance of tunneling FETs: bulk versus one-dimensional devices. Solid-State Electron 51:572–578

Gnani E, Gnudi A, Reggiani S, Baccarani G (2013) Drain-conductance optimization in nanowire TFETs by means of a physics-based analytical model. Solid-State Electron 84:96–102

Knoch J (2016) Chapter eight—nanowire tunneling field-effect transistors. Semicond Semimet 94:273–295

Appenzeller J, Knoch J, Bjork MT, Riel H, Schmid H, Riess W (2008) Toward nanowire electronics. IEEE Trans Electron Dev 55:2827–2845

Das A, Pisana S, Chakraborty B, Piscane S, Saha S, Waghmare U, Novoselov K, Krishanmurthy H, Geim A, Ferrari A, Sood A (2008) Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat Nanotechnol 3:210–215

Zhang Y, Tang T-T, Girit C, Hao Z, Martin M, Zettl A, Crommie M, Shen Y, Wang F (2009) Direct observation of a widely tunable bandgap in bilayer graphene. Nature 459:820–823

Knoch J, Chen Z, Appenzeller J (2012) Properties of metal-graphene contacts. IEEE Trans Nanotechnol 11:513–519

Xu H, Fathipour S, Kinder EW, Seabaugh AC, Fullerton-Shirey SK (2015) Reconfigurable ion gating of 2H-MoTe2 field-effect transistors using poly(ethylene oxide)-CsClO4 solid polymer electrolyte. ACS Nano 9:4900–4910

Wang Z, Wang F, Yin L, Huang Y, Xu K, Wang F, Zhan X, He J (2016) Electrostatically tunable lateral MoTe2 p-n junction for use in high-performance optoelectronics. Nanoscale 27:5534–5540

Baugher BWH, Churchill HOH, Yang Y, Jarillo- Herrero P (2014) Optoelectronic devices based on electrically tunable p–n diodes in a monolayer dichalcogenide. Nat Nanotechnol 9:262–267

Heinzig A, Slesazeck S, Kreupl F, Mikolajick T, Weber WM (2012) Reconfigurable silicon nanowire transistors. Nano Lett 12:119–124

Appenzeller J, Zhang F, Das S, Knoch J (2016) Transition metal dichalcogenide Schottky barrier transistors: a device analysis and material comparison. In "2D Materials for Nanoelectronics", CRC Press, Taylor and Francis Group, Boca Raton, p. 207–240

Mueller MR, Gumprich A, Schuette F, Kallis K, Kuenzelmann U, Engels S, Stampfer C, Wilck N, Knoch J (2014) Buried triple-gate structures for advanced field-effect transistor devices. Microelectron Engin 119:95–99

Mueller MR, Kallis K, Menzel S, Kuenzelmann U, Petrov I, Knoch J (2014) Tackling hillocks growth after aluminum CMP. Internat. Conf. Planarization/CMP Technol. (ICPT). 129–132

Kuenzelmann U, Mueller MR, Kallis KT, Schuette F, Menzel S, Engels S, Fong J, Lin C, Dysard J, Bartha JW, Knoch J (2012) Chemical-mechanical planarization of aluminium damascene structures, Internat. Conf. Planarization/CMP Technol. (ICPT); 1–6

Mueller MR, Gumprich A, Ecik E, Kallis KT, Winkler F, Kardynal B, Petrov I, Kunze U, Knoch J (2015) Visibility of two-dimensional layered materials on various substrates. J Appl Phys 118:145305

Knoch J, Zhang M, Mantl S, Appenzeller J (2006) On the performance of single-gated ultrathin-body SOI Schottky-barrier MOSFETs. IEEE Trans Electron Dev 53:1669–1674

Das S, Prakash A, Salazar R, Appenzeller J (2014) Toward low-power electronics: tunneling phenomena in transition metal dichalcogenides. ACS Nano 8:1681–1689

Das S, Appenzeller J (2013) Where does the current flow in two-dimensional layered systems? Nano Lett 13:3396–3402

Acknowledgments

The authors would like to thank the cleanroom teams of the University of Notre Dame and TU Dortmund University for their support. The partial financial support by the German Research Foundation (DFG) (grant number KN545/3-2) is acknowledged.

Authors’ contributions

MM carried out the bulk part of the device fabrication and wrote the paper. RS, SF and HX carried out device processing and did electrical measurements together with MM. KK and MM developed tha modified LOCOS process. UK and MM developed the chemical mechanical polishing process. AS, JA and JK provided device physics know-how and helped interpreting the experimental data. JK developed the layout of the BTG structures, provided processing know-how and revised the manuscript. All authors read and approved the final manuscript.

Competing interests

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Müller, M.R., Salazar, R., Fathipour, S. et al. Gate-Controlled WSe2 Transistors Using a Buried Triple-Gate Structure. Nanoscale Res Lett 11, 512 (2016). https://doi.org/10.1186/s11671-016-1728-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1728-7