Abstract

The goal of this research is to prepare inverted light-emitting devices with improved performance by combining titanium dioxide (TiO2) nanorods and tungsten trioxide (WO3) layer. TiO2 nanorods with different lengths were established directly on the fluorine-doped tin oxide (FTO) substrates by the hydrothermal method. The prepared TiO2 nanorods with lengths shorter than 200 nm possess transmittance higher than 80% in the visible range. Inverted light-emitting devices with the configuration of FTO/TiO2 nanorods/ionic PF/MEH-PPV/PEDOT:PSS/WO3/Au were constructed. The best device based on 100-nm-height TiO2 nanorods achieved a max brightness of 4493 cd/m2 and current efficiency of 0.66 cd/A, revealing much higher performance compared with those using TiO2 compact layer or nanorods with longer lengths as electron-transporting layers.

Similar content being viewed by others

Background

Organic light-emitting devices (OLEDs) have made impressive progress during the past two decades due to high luminance efficiency, wide viewing angle, flexibility, and low cost [1, 2]. They also show highly potential applications in the areas of displays and solid-state lighting. Despite those advantages, there still exist many challenges for organic light-emitting devices to replace liquid crystal displays and inorganic light-emitting diodes due to shorter lifetime at high luminescence and sensitivity to oxidation and humidity.

Conventional light-emitting devices are usually constructed with the configuration of anode/hole-transporting layer (HTL)/active layer/electron-transporting layer (ETL)/metal cathode. Poly(3,4-ethylenedioxythiophene): poly(styrene sulfonate) (PEDOT:PSS) is the most used material as HTL. However, the acidic nature of PEDOT:PSS can lead to the corrosion of the oxide anode; moreover, high-efficiency devices usually require highly active metals as the cathode, e.g., calcium or magnesium, which are easy to oxidize. In view of the above reasons, inverted light-emitting devices have been proposed and drawn increasing attention mainly due to higher stability compared with conventional ones. The usage of high work function metals such as gold (Au) or silver (Ag) as anode and air-stable metal oxide materials as carrier-transporting layers consequently prolongs lifetime of inverted-type devices. The architecture of inverted light-emitting devices is constructed with the configuration of cathode/ETL/active layer/HTL/metal anode [3, 4]. Many n-type metal oxide materials, including zinc oxide (ZnO), titanium dioxide (TiO2), and tin dioxide have been used as ETL [5–7]. On the other hand, p-type materials such as vanadium oxide, nickel oxide, and tungsten trioxide (WO3) can be utilized as HTL [8–10]. Taking TiO2 as an example, it is a well-known semiconducting material that possesses high thermal stability, good electron-transporting property, large energy bandgap of 3.0–3.4 eV, and friendly to our living environment [11]. TiO2 is normally a white solid; however, it can be transparent in thin film or in some nanostructured states. By changing the morphology of TiO2, it is expected that the optical and/or electrical transporting properties of TiO2 are also modified. In fact, nanostructured TiO2 have been applied in many areas, such as ultraviolet photodetectors [12], OLEDs [13], organic solar cells [14], and photocatalytic water-splitting technology [15]. Morii et al. reported encapsulation-free hybrid organic/inorganic light-emitting diodes with the configuration of fluorine-doped tin oxide (FTO)/TiO2/F8BT/MoO3/Au [16], using TiO2 as an electron injection layer (EIL) and MoO3 as a hole injection layer (HIL). The device could be operated in air with a lower threshold voltage that provided similar luminance output compared with conventional devices using Ca/Al as cathode. Bolink et al. reported inverted light-emitting devices with the configuration of indium tin oxide (ITO)/ZnO/Cs2CO3/super yellow PPV/MoO3/Au [17], using ZnO as an EIL and Cs2CO3 as a hole-blocking layer. High luminance and current efficiency of 12,000 cd/m2 and 6.5 cd/A were achieved that is comparable with conventional devices. Park et al. proposed inverted light-emitting devices with the configuration of ITO/ZnO/Cs2CO3/F8BT/PEDOT:PSS/Ag [18]. The Cs2CO3 layer was spin-cast into a thin film from its solution, not by thermal evaporation. A max luminance of 3399 cd/m2 and max current efficiency of 0.81 cd/A around 14–16 V were obtained. Song et al. further modified a device structure with the configuration of FTO/ZnO/FPQ-Br/F8BT/MoO3/Au [19], using an ionic polyfluorene (PF) derivative FPQ-Br tethering Br− counterions as the wetting agent to improve contact between inorganic ZnO and organic F8BT. Wen et al. employed a self-assembled monolayer PEDA-TMS to modify TiO2 surface for tuning its conduction band to match the energy level of high-yellow phenyl-substituted poly(para-phenylenevinylene) copolymer (HY-PPV). Inverted devices with the configuration of ITO/TiO2/PEDA-TMS/HY-PPV/MoO3/Au/Ag were fabricated, revealing much higher brightness of 3148 cd/m2 than that of the bare TiO2 device [20]. From literature survey, we notice that the above metal oxide materials were prepared and utilized as a thin film; TiO2 nanorods has not been reported in the light-emitting area so far. In addition to TiO2 and ZnO thin films, TiO2 nanorods are regarded as a potential candidate for the construction of light-emitting devices based on the following reasons. As mentioned in the previous part, TiO2 is a cheap, thermally stable, and non-toxic semiconducting material that is favorable for device fabrication and mass production. Moreover, nanorod-type TiO2 can provide one-dimensional pathways for carrier transportation. This is particularly beneficial for electrons to enter the device and to improve recombination rate of carriers. The transmittance of TiO2 in the visible region can also be tuned by experimental controls. From a scientific and industrial viewpoint, developing alternatives or new type of materials is an essential issue to expand the diversity of research instead of adopting limited materials.

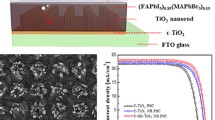

In this research, we demonstrate the preparation and characterization of TiO2 nanomaterials, including nanoparticles, nanorods, and compact layer, which can be used as an ETL for the fabrication of hybrid-inverted light-emitting devices. TiO2 nanorods and nanoparticles were prepared on the FTO substrates by the hydrothermal method without using either templates or seeds. This is because the FTO substrate also has the tetragonal rutile structure, and the lattice mismatch between the tetragonal FTO (a = b = 0.4687 nm) and the rutile TiO2 (a = b = 0.4593 nm) is only 2% [21]. To further improve device performance, ultra-thin layers of tungsten trioxide (WO3) and ionic PF derivative are incorporated. WO3 has been reported to serve as the HIL for application in organic light-emitting and photovoltaic devices [22–24]. The ionic PF material carrying hexafluorophosphate (PF6 −) counterions as wetting agent was synthesized and demonstrated in this study. Inverted light-emitting devices with the configuration of FTO/TiO2 nanorods/ionic PF/MEH-PPV/PEDOT:PSS/WO3/Au were fabricated and evaluated. The illustration of the device structure is shown in Fig. 1a, and the energy level diagram of the whole device is illustrated in Fig. 1b. It is seen that electron injection from FTO to TiO2 layer is undisturbed [25]. To overcome the large energy barrier between TiO2 and the active layer MEH-PPV, a thin layer of ionic PF was introduced; besides, this ionic PF also serves as the wetting layer to increase contact between inorganic TiO2 and organic MEH-PPV layers. On the other hand, the valence band of WO3 lies between the highest occupied molecular orbital of PEDOT:PSS and the work function of gold electrode that is favored for hole injection from the anode [22]. The PEDOT:PSS layer is incorporated between WO3 and the active layer to increase hole transfer. The recombination of electrons and holes in the active layer MEH-PPV results in electroluminescence (EL) under bias operation. The features of inverted architecture and solution process for deposition of organic and inorganic layers in this study provide a promising way to low-cost manufacturing in the future.

Methods

Polymer Materials

The light-emitting polymer poly(2-methoxy-5-(2′-ethylhexyloxy)-1,4- phenylenevinylene) (MEH-PPV) was synthesized according to the literature [26]. PEDOT:PSS aqueous solution (CleviosTM P VP AI 4083) was purchased from Heraeus Precious Metals GmbH & Co. KG. Titanium(IV) n-butoxide and Titanium(IV) chloride was purchased from Alfa. Ammonium hexafluorophosphate was purchased from Matrix Scientific. Hydrochloric acid was purchased from ECHO Chemical. The solvents including methanol, acetonitrile, toluene, and ethanol were also purchased from ECHO Chemical. These reagents and solvents were used as received without further purification. The ionic PF carrying PF6 − groups was synthesized by ionic exchange from its precursor PF-Br according to the previous literatures [27]. The detailed synthetic procedure of this ionic PF is described as follows. To a solution of PF-Br (100 mg) in methanol (20 mL) was slowly added a solution of ammonium hexafluorophosphate (0.4 g, 4.8 mmol) in methanol (20 mL). The mixture was stirred at room temperature for 48 h, followed by removing the solvent by rotary evaporation. The previous procedure was repeated for 4 or 5 times to achieve high percentage of ionic exchange from Br− to PF6 −. The final product was collected and dried in an oven to give a yellow solid (90 mg, 75%). The chemical structures of the above materials are shown in Fig. 2a.

Preparation of TiO2 Nanomaterials

The schematic illustration of the growth of TiO2 nanoparticles and nanorods on FTO substrates by the hydrothermal method [28] is shown in Fig. 2b, and the detailed preparation is described as follows. Thirty-seven percent Hydrochloric acid (20 mL) was added in 20 mL of deionized water and stirred for 10 min. Titanium(IV) n-butoxide (0.7 mL) was then added and stirred for an additional 10 min. The solution mixture was transferred into the autoclave in which the FTO substrates were placed at an angle against the wall of the teflon-liner. The autoclave was placed in a preheated oven at 170 °C. The growth time was set to 100, 110, 120, and 130 min. TiO2 nanoparticles were formed with the growth time of 100 min, while nanorods with lengths of 100, 200, and 300 nm were obtained with the growth time of 110, 120, and 130 min, respectively. The substrates were taken out, rinsed thoroughly with deionized water, and calcined at 450 °C in air for 1 h. The TiO2 compact layer was also prepared via the chemical bath deposition for comparison in this study [29]. A solution of 1 M TiCl4 in toluene (1 mL) was added in 4 mL of deionized water dropwise at 0 °C and stirred for 5 min. The FTO substrates were then immersed into this solution and placed in an oven at 70 °C for 1 h. The substrates were taken out, washed with deionized water and ethanol, and calcined at 450 °C in air for 1 h.

Fabrication of Inverted Light-Emitting Devices

Inverted light-emitting devices with the configuration of FTO/TiO2 nanomaterials/ionic PF/MEH-PPV/PEDOT:PSS/WO3/Au were fabricated. The device architecture is shown in Fig. 1a. The ionic PF in acetonitrile (1 mg/1 mL) was spin-coated on top of the TiO2 layer, followed by drying in a vacuum oven at 90 °C for 30 min. MEH-PPV film (150 nm) was spin-cast from its toluene solution (15 mg/1 mL) and dried in a vacuum oven at 90 °C for 30 min. PEDOT:PSS layer (50 nm) was spin-cast on top of MEH-PPV and baked in a vacuum oven at 90 °C for 30 min. WO3 layer (5 nm) was prepared by spin-coating from its precursor solution (1 mg of W(OEt)5 in 1 mL of anhydrous ethanol) and placed in ambient environment for 15 min. Finally, Au electrodes were deposited by thermal evaporation at a base pressure of 10−6 torr. The active area of each device is 4 mm2.

Characterization Methods

The transmission and absorption spectra of TiO2 nanomaterials were measured with a Princeton Instruments Acton 2150 spectrophotometer. The surface morphology of the materials was studied using the tapping-mode Bruker Innova atomic force microscopy (AFM). Cross-sectional scanning electron microscopy (SEM) micrographs of devices were performed with a JEOL 6700 F SEM. X-ray diffraction (XRD) patterns were obtained from a Rigaku D/MAX2500 diffractometer. The electrical and emission characteristics of light-emitting devices were measured using an Agilent 4155C semiconductor analyzer and a calibrated silicon photodiode.

Results and Discussion

Morphological Studies of TiO2 Nanomaterials

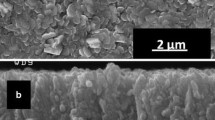

The SEM micrographs of TiO2 nanomaterials on the FTO substrates are shown in Fig. 3. TiO2 nanoparticles under growth time of 100 min are sparsely dispersed on the surface of FTO, and the diameters of those TiO2 nanoparticles are estimated to be 20–30 nm, as verified in Fig. 3a and f. The growth and dispersion of TiO2 nanoparticles on the FTO is caused by the homogeneous nucleation of TiO2 [30, 31]. When the growth time prolongs to 110 min, TiO2 nanoparticles can serve as the seeds for further growth of nanorods as well as the heterogeneous nucleation of TiO2. It is seen that TiO2 nanorods are mainly grown upwards, with some nanorods tilt on the FTO substrates. From the SEM side view in Fig. 3b–d, the lengths of TiO2 nanorods are estimated to be 100, 200, and 300 nm when the growth time is set to 110, 120, and 130 min, respectively. From the SEM top view in Fig. 3g-i, the diameters of TiO2 nanorods is determined in the range of 40–80 nm. The lengths and diameters are concluded to be dependent on the growth time [25], i.e., nanorods grow longer and wider as the growth time increases. Besides, the FTO substrates are not fully covered by TiO2 nanoparticles or nanorods when the growth time is set shorter than 120 min. The SEM side view and top view images of TiO2 compact layer are shown in Fig. 3e and j, respectively. Large amounts of crystalline nanoparticles with total thickness of 100 nm are clearly observed for TiO2 compact layer, which is very different from those nanorods. The chemical stoichiometry of Ti and O atoms in the nanorods is examined with an energy dispersive X-ray spectroscopy (EDX) analyzer and shown in Fig. 3k. It indicates the presence of Ti and O with an atomic ratio of 1:2.25 that is in agreement with the stoichiometric composition of TiO2 [30]. The total surface area of TiO2 nanorods are supposed to be larger than the compact layer due to high aspect ratio of nanorods, which might show positive effect on carrier injection and transportation. Due to different surface properties (TiO2 is hydrophilic and organic materials are hydrophobic), an ionic PF was introduced between TiO2 and organic layer to serve as the wetting layer. The AFM topographic images of TiO2 nanorods and compact layer are shown in Fig. 4. Rod-like and particle-like morphologies are observed for TiO2 nanorods and compact layer, with surface roughness (R a ) of 26.8 and 17.7 nm, respectively.

Optical Properties of TiO2 Nanomaterials

The transmission and absorption spectra of TiO2 nanomaterials on the FTO substrates were measured and shown in Fig. 5. The transmittance of TiO2 nanorods drops sharply in the range of 330–380 nm, arising from the nature of TiO2 absorption. For TiO2 nanoparticles, compact layer, and nanorods with lengths of 100 and 200 nm, the transmittance reaches over 80% in the visible range of 380–700 nm. As for TiO2 nanorods with a length of 300 nm, the transmittance is significantly lower than others due to longer height of nanorods and full coverage of FTO substrate. Nevertheless, moderate to high transparent property of TiO2 nanomaterials is suitable for optoelectronic applications. The main absorption band of TiO2 is observed from 300 to 380 nm. The absorption edges of TiO2 nanorods and compact layer are found at 400 and 380 nm, respectively. The band gap of the TiO2 nanorods and compact layer were then calculated from their absorption edges to be were 3.10 eV and 3.25 eV, respectively, which is in good accordance with the previous reports [32].

XRD Patterns of TiO2 Nanomaterials

The XRD patterns of the 300-nm-height TiO2 nanorods and 100-nm-thick compact layer on FTO substrate is presented in Fig. 6a, which is in good accordance with that of the rutile phase (JCPDS No. 88–1175) [30]. These diffraction peaks are sharp and strong, indicating high-degree crystallization of the prepared TiO2 nanomaterials in this research. The five main diffraction peaks located at 2θ = 36.07°, 41.24°, 54.33°, 62.75°, and 29.3° are assigned to (101), (111), (211), (002), and (112) planes, respectively [30]. The highly intense (101) peak along with the enhanced (002) peak in the nanorods reveals that the rutile crystal grows with (101) plane parallel to the FTO substrate, and the nanorods are oriented along the (002) direction [33]. The diffraction peaks from the FTO substrates are also indicated in Fig. 6. Only two diffraction peaks assigning to (101) and (211) planes can be observed for TiO2 compact layer. The difference in XRD intensity between TiO2 nanorods and compact layer arises from different thickness of the layer. Besides, the mobility of rutile TiO2 nanorods is reported to be 1 cm2/Vs, which is two-order higher than that of TiO2 nanoparticles layer [33, 34]. The higher electron-transporting properties brought by the nanorod form are beneficial for device performance.

Device Performance Based on TiO2 Nanomaterials

Inverted light-emitting devices with the configuration of FTO/TiO2/ionic PF/MEH-PPV/PEDOT:PSS/WO3/Au were fabricated and evaluated, using TiO2 as electron-transporting layer, ionic PF as wetting layer, MEH-PPV as active layer, PEDOT:PSS as hole-transporting layer, and WO3 as hole-injecting layer. The brightness-voltage (B-V), current efficiency-current density (E-J) characteristics, and EL spectra of all devices are depicted in Fig. 7a–c. The overall device performance based on different types of TiO2 is summarized in Table 1. The max brightness and current efficiency of the device based on TiO2 nanoparticles reached 333 cd/m2 and 0.08 cd/A, respectively. By using TiO2 compact layer as an ETL, the device performance was promoted with max brightness of 790 cd/m2 and current efficiency of 0.15 cd/A. The reason to the improved performance is due to full coverage of FTO surface by the TiO2 compact layer that reduces charge trapping and quenching on FTO anode. Turing to TiO2 nanorods, the max brightness achieved 4493, 2589, and 1090 cd/m2 for the devices based on 100, 200, and 300-nm-height nanorods, respectively. Furthermore, the current efficiency was decreased from 0.66 to 0.05 cd/A as the length of TiO2 nanorods was increased. The reason to this phenomenon can be explained as follows. First, TiO2 nanorods with length of 100 nm own the highest transmittance among three lengths of nanorods, which is beneficial for light output. Second, 100-nm TiO2 nanorods provide shorter pathways for carrier injection to the active layer to generate light. We also notice that the devices based on TiO2 nanorods revealed much better device performance than others using TiO2 nanoparticles or compact layer as an ETL. This is due to higher mobility of TiO2 nanorods that is favored for carrier transport than the other two TiO2 nanomaterials, as described in the previous section. Figure 7c shows the original EL spectra of the inverted devices based on TiO2 nanomaterials operated at 12 V. The emission maximum wavelength and shoulder emission are located at 588 and 630 nm, respectively, revealing an orange-red light. A very bright inverted light-emitting device based on 100-nm-height TiO2 nanorods under driving bias of 15 V is shown in Fig. 7d. Figure 8a shows the relationship between the transmittance of TiO2 nanorods and the brightness of devices. The value of transmittance was chosen at 588 nm, since the device emitted light at the same wavelength. It is seen that TiO2 nanorods with higher transmittance bring higher brightness. To clarify the relationship between nanorod length and transmittance/brightness, the characteristics transmittance-nanorods and length-brightness are depicted and shown in Fig. 8b. As the nanorod length is increased, both transmittance and brightness are decreased. It is noted that the transmittance as well as the brightness of the devices in the whole visible region should be taken into account to completely understand the transmittance effect on the brightness of the devices, not only at 588 nm. Figure 9 shows the luminance decay curve as a function of time for the device based on 100-nm-height TiO2 nanorods. The device was monitored at a constant voltage of 10 V in ambient environment without encapsulation. The lifetime of the device is defined as the time when the luminance is decreased to a half of its initial luminance, which is determined about 40 h. The stability test of inverted OLEDs is seldom reported in the literature. G. He et al. reported the inverted OLEDs with the configuration of ITO/Cs2CO3/Bphen/Alq3/NPB/MoO3/Au [35]. The device lifetime was only 20 h when using Cs2CO3 as the EIL. By inserting a thin layer of aluminum between ITO and Cs2CO3, the luminance of the device decayed to 80% of its initial value during an operation time of 70 h. In our case, the usage of TiO2 nanorods as the ETL can provide moderate stability in ambient condition. To the best of our knowledge, this is the first demonstration of inverted light-emitting devices using TiO2 nanorods as ETL. These results suggest that TiO2 nanorods may possess potential use in light-emitting applications.

Conclusions

TiO2 nanoparticles with diameter of 20–30 nm and nanorods with different lengths of 100–300 nm were prepared by the hydrothermal method. TiO2 compact layer was prepared by chemical bath deposition for comparison. The results showed that rutile TiO2 was obtained, and nanorods with shorter length of 100–200 nm showed higher transmittance in the visible range of 380–700 nm. Inverted light-emitting devices using different TiO2 nanomaterials as ETL were fabricated and compared. The device based on 100-nm-height TiO2 nanorods revealed the best device performance among all devices, with a max brightness and max current efficiency of 4493 cd/m2 and 0.66 cd/A, respectively.

Abbreviations

- AFM:

-

Atomic force microscopy

- B-V:

-

Brightness-voltage

- EDX:

-

Energy dispersive X-ray spectroscopy

- EIL:

-

Electron injection layer

- E-J:

-

Current efficiency-current density

- EL:

-

Electroluminescence

- ETL:

-

Electron-transporting layer

- FTO:

-

Fluorine-doped tin oxide

- HIL:

-

Hole injection layer

- HTL:

-

Hole-transporting layer

- ITO:

-

Indium tin oxide

- MEH-PPV:

-

Poly(2-methoxy-5-(2′ethylhexyloxy)-1,4-phenylenevinylene)

- OLEDs:

-

Organic light-emitting devices

- PEDOT:PSS:

-

Poly(3,4-ethylenedioxythiophene): poly(styrene sulfonate)

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

References

Geffroy B, le Roy P, Prat C (2006) Organic light-emitting diode (OLED) technology: materials, devices and display technologies. Polym Int 55:572–582

Shinar J, Shinar R (2008) Organic light-emitting devices (OLEDs) and OLED-based chemical and biological sensors: an overview. J Phys D Appl Phys 41:133001

Sessolo M, Bolink HJ (2011) Hybrid organic–inorganic light-emitting diodes. Adv Mater 23:1829–1845

Takada M, Kobayashi T, Nagase T, Naito H (2016) Inverted organic light-emitting diodes using different transparent conductive oxide films as a cathode. Jpn J Appl Phys 55:03DC06

Faria JCD, Campbell AJ, McLachlan MA (2015) ZnO nanorod arrays as electron injection layers for efficient organic light emitting diodes. Adv Funct Mater 25:4657–4663

Xu W, Ji W, Jing P, Yuan X, Wang YA, Xiang W, Zhao J (2014) Efficient inverted quantum-dot light-emitting devices with TiO2/ZnO bilayer as the electron contact layer. Opt Lett 39:426–429

Lee H, Kang CM, Park M, Kwak J, Lee C (2013) Improved efficiency of inverted organic light-emitting diodes using tin dioxide nanoparticles as an electron injection layer. ACS Appl Mater Interfaces 5:1977–1981

Wu J, Hou J, Cheng Y, Xie Z, Wang L (2007) Efficient top-emitting organic light-emitting diodes with a V2O5 modified silver anode. Semicond Sci Technol 22:824–826

Park SW, Choi JM, Kim E, Im S (2005) Inverted top-emitting organic light-emitting diodes using transparent conductive NiO electrode. Appl Surf Sci 244:439–443

Kim YH, Kwon S, Lee JH, Park SM, Lee YM, Kim JW (2011) Hole injection enhancement by a WO3 interlayer in inverted organic light-emitting diodes and their interfacial electronic structures. J Phys Chem C 115:6599–6604

Landmann M, Rauls E, Schmidt WG (2012) The electronic structure and optical response of rutile, anatase and brookite TiO2. J Phys Condens Matter 24:195503

Wang L, Yang W, Chong H, Wang L, Gao F, Tian L, Yang Z (2015) Efficient ultraviolet photodetectors based on TiO2 nanotube arrays with tailored structures. RSC Adv 5:52388–52394

Gupta N, Grover R, Mehta DS, Saxena K (2015) Efficiency enhancement in blue organic light emitting diodes with a composite hole transport layer based on poly(ethylenedioxythiophene): poly(styrenesulfonate) doped with TiO2 nanoparticles. Displays 39:104–108

Ke W, Fang G, Wang J, Qin P, Tao H, Lei H, Liu Q, Dai X, Zhao X (2014) Perovskite solar cell with an efficient TiO2 compact film. ACS Appl Mater Interfaces 6:15959–15965

Yu J, Qi L, Jaroniec M (2010) Hydrogen production by photocatalytic water splitting over Pt/TiO2 nanosheets with exposed (001) facets. J Phys Chem C 114:13118–13125

Morii K, Ishida M, Takashima T, Shimoda T, Wang Q, Nazeeruddin MK, Grätzel M (2006) Encapsulation-free hybrid organic–inorganic light-emitting diodes. Appl Phys Lett 89:183510

Bolink HJ, Coronado E, Orozco J, Sessolo M (2009) Efficient polymer light-emitting diode using air-stable metal oxides as electrodes. Adv Mater 21:79–82

Phuong PTT, Kim NY, Jung S, Kang JW, Kim HW, Lee KH, Park SJ (2013) Improved performance of inverted hybrid light-emitting diodes by post-annealed ZnO electron transport layer. J Photonic Sci Technol 3:41–46

Lee BR, Lee W, Nguyen TL, Park JS, Kim JS, Kim JY, Woo HY, Song MH (2013) Highly efficient red-emitting hybrid polymer light-emitting diodes via Förster resonance energy transfer based on homogeneous polymer blends with the same polyfluorene backbone. ACS Appl Mater Interfaces 5:5690–5695

Hsieh SN, Chen SP, Li CY, Wen TC, Guo TF, Hsu YJ (2009) Surface modification of TiO2 by a self-assembly monolayer in inverted-type polymer light-emitting devices. Org Electron 10:1626–1631

Guo K, Liu Z, Zhou C, Han J, Zhao Y, Liu Z, Li Y, Cui T, Wang B, Zhang J (2014) Fabrication of TiO2 nano-branched arrays/Cu2S composite structure and its photoelectric performance. Appl Catal B Environ 154–155:27–35

Höfle S, Bruns M, Stässle S, Feldmann C, Lemmer U, Colsmann A (2013) Tungsten oxide buffer layers fabricated in an inert sol–gel process at room-temperature for blue organic light-emitting diodes. Adv Mater 25:4113–4116

Tan Z, Li L, Cui C, Ding Y, Xu Q, Li S, Qian D, Li Y (2012) Solution-processed tungsten oxide as an effective anode buffer layer for high-performance polymer solar cells. J Phys Chem C 116:18626–18632

Meyer J, Winkler T, Hamwi S, Schmale S, Johannes HH, Weimann T, Hinze P, Kowlasky W, Riedl T (2008) Transparent inverted organic light-emitting diodes with a tungsten oxide buffer layer. Adv Mater 20:3839–3843

Xi J, Wiranwetchayan O, Zhang Q, Liang Z, Sun Y, Cao G (2012) Growth of single-crystalline rutile TiO2 nanorods on fluorine-doped tin oxide glass for organic–inorganic hybrid solar cells. J Mater Sci Mater Electron 23:1657–1663

Neef CJ, Ferraris JP (2000) MEH-PPV: improved synthetic procedure and molecular weight control. Macromolecules 33:2311–2314

Kang R, Oh SH, Kim DY (2014) Influence of the ionic functionalities of polyfluorene derivatives as a cathode interfacial layer on inverted polymer solar sells. ACS Appl Mater Interfaces 6:6227–6236

Liu B, Aydil ES (2009) Growth of oriented single-crystalline rutile TiO2 nanorods on transparent conducting substrates for dye-sensitized solar cells. J Am Chem Soc 131:3985–3990

Yella A, Heiniger LP, Gao P, Nazeeruddin MK, Grätzel M (2014) Nanocrystalline rutile electron extraction layer enables low-temperature solution processed perovskite photovoltaics with 13.7% efficiency. Nano Lett 14:2591–2596

Han Y, Fan C, Wu G, Chen HZ, Wang M (2011) Low-temperature solution processed ultraviolet photodetector based on an ordered TiO2 nanorod array–polymer hybrid. J Phys Chem C 115:13438–13445

Hosono E, Fujihara S, Kakiuchi K, Imai H (2004) Growth of submicrometer-scale rectangular parallelepiped rutile TiO2 films in aqueous TiCl3 solutions under hydrothermal conditions. J Am Chem Soc 126:7790–7791

Tamilselvan V, Yuvaraj D, Kumar RR, Rao KN (2012) Growth of rutile TiO2 nanorods on TiO2 seed layer deposited by electron beam evaporation. Appl Surf Sci 258:4283–4287

Kim HS, Lee JW, Yantara N, Boix PP, Kulkarni SA, Mhaisalkar S, Grätzel M, Park NG (2013) High efficiency solid-state sensitized solar cell-based on submicrometer rutile TiO2 nanorod and CH3NH3PbI3 perovskite sensitizer. Nano Lett 13:2412–2417

Hendry E, Koeberg M, O’Regan B, Bonn M (2006) Local field effects on electron transport in nanostructured TiO2 revealed by terahertz spectroscopy. Nano Lett 6:755–759

Liu J, Wu X, Shi X, Wang J, Min Z, Wang Y, Yang M, He G (2015) Highly efficient and stable electron injection layer for inverted organic light-emitting diodes. ACS Appl Mater Interfaces 7:6438–6443

Acknowledgements

The authors thank the Ministry of Science and Technology (MOST 104-2221-E-009-187) of the Republic of China for the financial support of this work.

Funding

This work was supported by the Ministry of Science and Technology of the Republic of China under Contract No. MOST 104-2221-E-009-187.

Authors’ Contributions

TYT proposed the research idea, performed the experiments, and drafted the manuscript. PRY participated in the sample preparation. SHY contributed to the data interpretation and the manuscript writing and supervised the research. All authors read and approved the final manuscript.

Competing Interests

The authors declare that they have no competing interests.

Ethics Approval and Consent to Participate

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tsai, TY., Yan, PR. & Yang, SH. Solution-Processed Hybrid Light-Emitting Devices Comprising TiO2 Nanorods and WO3 Layers as Carrier-Transporting Layers. Nanoscale Res Lett 11, 516 (2016). https://doi.org/10.1186/s11671-016-1733-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1733-x