Abstract

Recently, various resistance-based memory devices are being studied to replace charge-based memory devices to satisfy high-performance memory requirements. Resistance random access memory (RRAM) shows superior performances such as fast switching speed, structural scalability, and long retention. This work presented the different filament control by the DC voltages and verified its characteristics as a synaptic device by pulse measurement. Firstly, two current–voltage (I–V) curves are characterized by controlling a range of DC voltages. The retention and endurance for each different I–V curve were measured to prove the reliability of the RRAM device. The detailed voltage manipulation confirmed the characteristics of multi-level cell (MLC) and conductance quantization. Lastly, synaptic functions such as potentiation and depression, paired-pulse depression, excitatory post-synaptic current, and spike-timing-dependent plasticity were verified. Collectively, we concluded that Pt/Al2O3/TaN is appropriate for the neuromorphic device.

Similar content being viewed by others

Introduction

In an environment where data demand is rapidly increasing, a breakthrough is needed in computing performance limitations due to serial processing of CPU and memory [1]. It is necessary to change the computing structure and improve the materials of the memory device to solve the memory wall. Neuromorphic computing architecture is emerging as a structural solution to the bottleneck. The neuromorphic computing system mimics the neuron and synapses of the human brain [2,3,4]. This system is suitable for the process of complex and unstructured information. First of all, to implement neuromorphic computing, it is necessary to understand how the human brain processes information. The human brain includes numerous synapses and neurons, and learning and memory of information proceed through parallel chemical interactions. Information processing and memory capabilities vary depending on various factors such as the size, holding time, and a repetition time of external signals and stimuli [5,6,7].

Among various memories, the RRAM exhibits a fast switching speed and a low operating voltage [8,9,10,11,12,13,14,15]. In addition, RRAM could be implemented in a simple structure such as a metal-oxide-metal (MIM) with various structural expandability [16,17,18,19,20,21] such as the connection of transistor with each memory cell, an array structure, and a 3D vertical structure.

The switching of RRAM occurs by the formation and rupture of filament in an insulator between the metals [22,23,24,25,26]. The resistance of RRAM is varied through a conductive filament composed of oxygen vacancy in the insulator existing between the top electrode (TE) and bottom electrode (BE) and has two basic switching states (high and low) to process the data storage process [20, 27,28,29,30]. In the case of the high-resistance state (HRS), a low current flows in HRS, and in the case of the low-resistance state (LRS), it means a state has low resistance and good conductivity. Accordingly, the on/off state could be monitored through the read voltage. The repetition of set and reset processes cause the device to move back and forth between the HRS and LRS, which can be described as a memory that stores 0 and 1 from a digital perspective.

In this paper, the gradual resistive switching is conducted on Pt/Al2O3/TaN device, including Al2O3 high-k dielectric [31,32,33,34,35], which was deposited by atomic layer deposition (ALD) equipment. The characteristics using basic DC current sweep and on/off endurance characteristics were measured, and the suitability of neuromorphic devices was also measured through synaptic measurement, including potentiation, depression, PPD, EPSC, and STDP.

Experiments

Pt/Al2O3/TaN device was fabricated as follows. Firstly, TaN as BE was deposited by the sputtering system on SiO2/Si wafer. A 5-nm-thick Al2O3 film was deposited by the ALD process. In the ALD process, TMA precursors and O3 were used at stage temperature 450 °C. Then a 100-nm-thick Pt as TE was deposited by evaporator in which the top pattern was formed in a circular pattern by using a shadow mask with a diameter of 100 µm. For the measurement environment, all measurements were performed at room temperature and ambient atomic pressure. Electrical data were measured using the Keithley 4200-SCS semiconductor parameter ultrafast module and in pulse mode using a 4225-PMU ultrafast module.

Results and Discussion

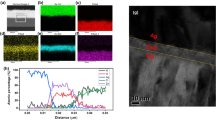

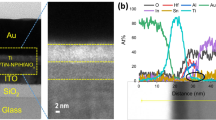

Figure 1a shows the schematic illustration of the fabricated Pt/Al2O3/TaN device. In Fig. 1b, the cross section of the Pt/Al2O3/TaN RRAM device is inspected by a transmission electron microscope (TEM). The thickness of the Al2O3 insulator layer deposited by the ALD system is about 5 nm. In Fig. 1c, energy dispersion X-ray spectroscopy (EDS) mapping of each element was performed to investigate possible chemical interactions. EDS mapping shows the spatial distribution of elements in Pt/Al2O3/TaN. EDS maps of Pt, Al, O, Ta, and N elements were collected in the area shown in the electronic image. A region where O and Ta overlap is observed, indicating The TaON interface layer between the Al2O3 insulator and TaN BE is formed by a chemical redox reaction between the TaN BE and the lower Al2O3 layer due to the strong oxygen binding of TaN [36,37,38]. Because of the formation of the TaON interface layer by extracting oxygen from the Al2O3 layer by TaN, better switching characteristics could be exhibited according to the formation of the oxygen vacancy near the TaON/Al2O3 interface [38].

In order to confirm the TaON layer, the X-ray photoelectron spectroscopy (XPS) spectra fittings were conducted. Figure 2a shows the Al 2p XPS spectra in which peak intensity is located at 75 eV for Al–O bonding [39]. Figure 2b and c shows Ta 4f and N 1s XPS peak for the TaON layer. In Fig. 2b, small peaks exist at higher binding energy than general Ta 4f XPS peaks. This indicates that the binding Ta–O or Ta–Al energy also affected the Ta 4f XPS peaks with binding Ta–N energy [40, 41]. From Fig. 2c, through combination with oxygen, N 1s XPS peak shows more biased to higher binding energy than the normal N 1s peak [42]. As a result, a thin layer of TaON exists between the Al2O3 insulator and the TaN BE.

Next, we investigate two types of bipolar resistive switching by DC sweep. All of the above I–V characteristics were measured at a step voltage of 0.01 V. Representative feature of this device shows forming-free characteristics in Fig. 3a [43]. The set process has similar I–V curves as the forming process, and the set process occurs at − 2 V or higher, and the reset process is induced by applying a 2.75 V. This is referred to as a deep reset curve. At this time, the on/off ratio is about 45,000 based on the read voltage of 0.5 V, which is a characteristic due to a large band gap of Al2O3. Set shows abrupt behavior, and in the reset process, it shows a curve that returns to the HRS state with a stepwise drop from 1 V or higher to 2.7 V. In the case of Fig. 3b, unlike Fig. 3a, it can be implemented by adjusting reset voltage less than 2.75 V. This is referred to as a partial reset curve, and the on/off ratio at this time is about 13 at the read voltage of 0.5 V. Compared to the I–V curves with fully reset, the I–V curves with partial reset process shows more gradual characteristics in the set and reset processes. Both I–V characteristics have self-compliance characteristics [44]. The method of connecting the two differences in Fig. 3a and b can be confirmed by a continuous DC sweep in Fig. 3c. The deep reset occurs when the larger voltage is applied, indicating that the strength of the reset can be controlled by the voltage adjustment. The current flows in the HRS induced by the partial reset and an additional reset occur, which lowers the current level due to additional filament decomposition. Figure 3d exhibits a possible switching mechanism of partial reset (left) and deep reset (right) curves. As confirmed in Fig. 2, Al–O bonding has higher binding energy than that Ta–O bonding. This suggests that switching depends on the TaON layer when the small electric field is applied and on the Al2O3 layer when it is a large electric field. Thus, oxygen ions formed between TaN and TaON affect the conduction mechanism of the device and are estimated to result in MLC characteristics [3, 45, 46]. Gradual partial reset with MLC occurs in the TaON layer within the − 2.2 V region. However, the more electric field induces the filament decomposition inside the Al2O3 and causes the abrupt current decrease during the reset process. In Fig. 3e, HRS and LRS were confirmed in the read operation of 0.5 V to demonstrate state uniformity. Since the filament decomposition depends on the magnitude of reset voltage, HRS varies more severely than LRS. Also, more decomposition demands more set voltage to re-form the filaments. Variation of set voltage is shown in Fig. 3f and it varied from − 1.25 to − 0.75 V in accordance with the previous reset cycle process.

In Fig. 4a, the endurance characteristics were also measured for partial I–V conditions using pulse for 105 cycles. It shows that HRS and LRS can be switched even at 105 or more times. In Fig. 4b, it is the result of performing the retention test for each I–V characteristic including partial and deep resets. HRS and LRS were measured at the read voltage of 0.15 V, and both states were maintained for 104 s. These results show the Pt/Al2O3/TaN device has good non-volatile memory properties. Multi-level cell characteristics are very beneficial for practical applications such as high-density memory and neuromorphic device [43, 47, 48]. Figure 4c shows a reset process by increasing the reset voltage by 0.2 V for each cycle. Through this process, as the reset voltage increases, multiple HRS is achieved. In Fig. 4d, based on the reset voltage at the boundary between the partial reset and deep reset, the reset process was repeatedly measured while increasing 0.025 V from 1.8 to 2.35 V. It could be verified that the current level gradually decreases, and this could prove the existence of various multi-level states.

The property of conductance quantization [49,50,51,52] was confirmed. This is thought to be due to the quantization effect of conductive filament during the reset process. When the conductive filament is well controlled, it is possible to implement more state and higher density memory through this phenomenon. As shown in Fig. 5a, this phenomenon can be observed when the conductive filament is modified in atomic units. The step voltage of 0.002 V and delay time of 0.3 s every step is used to observe quantization in multiple cycles, and only elemental disruption of the filament was measured during the reset process. The conductance quantum, represented by the symbol G0, is the quantized unit of electrical conductance. It is defined by the elementary charge e and Planck constant h as G0 = 2e2/h = 7.74809 × 10–5 S. The device takes an integer multiple of G0 or an intermediate value between integers. In the end, LRS is changed to HRS. The statistical analysis is essential through multiple cycles [53,54,55,56,57]. Figure 5b shows the histogram plotting, and it can be seen that even in various conductance steps, there is a high tendency near a multiple of G0 or a half multiple [58,59,60,61]. It is noted the values between 0.5G0 and 3G0 are distinctly distinguishable. It may be necessary to make the conducting filament smaller by means of a method such as making the device smaller in order to distinguish the quantized values. Pulse measurements were performed in Fig. 5c and d to describe the quantized conductance [62,63,64]. Conductance calculated with the voltage of 0.5 V was induced by adding write pulses at 0.5 s intervals. In Fig. 5c, an incremental write pulse increased by − 25 mV from − 0.7 to − 1.775 V was used and the abrupt set operation occurred at a voltage of − 1 V or higher. The conductance in HRS increases more than 10G0 at a time due to the abrupt characteristic in the set region. This characteristic was also confirmed in the I–V curve in the inset image of Fig. 5c, which MLC implemented by limiting compliance current. In contrast, conductance quantization with the erase pulses composed by 25 mV from 1.5 to 2.175 V were ranged of about G0. From those two different conductance ranges show that it is more ease to implement MLC during reset process due to the clear state distinction.

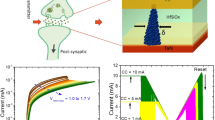

A neuromorphic computing system can be implemented using multi-level cells in Pt/Al2O3/TaN devices. As shown in Fig. 6a, the conductive filament connecting the TE and BE of RRAM can be expressed very similarly to the human’s biological system [43, 65,66,67]. In order to confirm the suitability of neuromorphic computing, pulse measurements were conducted. In Fig. 6b, conductance control is continuously performed through 5 cycles of potentiation and depression by applying the pulses. Potentiation and depression were set to − 1.15 V and 1.3 V, respectively, and both pulse widths were set to 10 sµ. From the I–V characteristic of the set process, relatively abruptness in the potentiation can be confirmed. It could be verified that the depression part has a more gradual characteristic. Moreover, we demonstrate more gradual and symmetric resistance-change characteristics by controlling the voltage amplitude of pulses in Fig. 6c [68, 69]. Each 6 potentiation and depression segments are used to increase and decrease the conductance. The voltage varied from − 0.9 to − 1.4 V for potentiation and from 1.35 to 2.85 V for depression. Figure 6d shows MNIST pattern recognition simulation results by using the conductance results of Fig. 6b and c [70, 71]. The result of using Fig. 6c shows higher accuracy for each epoch. In other words, pulse improvement measurement provides a better learning process.

Synaptic functions, such as PPD, EPSC, and STDP measurements, were performed to determine suitability for the neuromorphic application [72,73,74]. Figure 7a shows the device's PPD measurement data, the ratio change between two pulses was confirmed when the seven different intervals were used. Synaptic weight changed with the time interval ranging from 20 μs to 5 ms between two consecutive depression pulses. The amount of synaptic weight change was expressed as ΔW = (A2 − A1)/A1 × 100 (%). As a result, the current responded by the second pulse decreases as the interval increases, indicating that the device is suitable for implementing STP. Figure 7b illustrates conductance changes before and after giving five identical write pulses and summarizes them with pulse amplitudes. As the voltage amplitude increases, both potentiation and depression have a larger synaptic weight change. Continuous stimulation raises EPSC; the degree of weight strengthening can be adjusted according to the amplitude. The strength of connections between neurons in biological synapses can be controlled by STDP. Therefore, if we can elucidate the detailed mechanisms of biological synaptic action and imitate the action behavior, it will be possible to mimic the energy-efficient processing of the human brain. Figure 7c explains the configuration of the STDP protocol. When the pre-spike signal and post-spike signal, which vary with the interval, were applied to the biological synapses, the weight was changed and implemented according to the learning behavior. This process was mimicked on the memristor in the same way. The pulse protocol in Fig. 7d was used for the measurements. The same pre and post-signal were composed, but the different shape of pulses was finally configured and applied according to the interval. Since the final pulse configuration was different, the synaptic weights over time had different weight changes, as shown in Fig. 7e [2, 75, 76]. In general, the shorter the absolute time of the spike time difference, the greater the change in conductance change like a biological synapse.

Conclusions

As a result, the MLC characteristics and quantized conductance were confirmed through the Al2O3-based RRAM device deposited with ALD, and excellent biological characteristics were investigated through pulse measurement. DC I–V bipolar switching characteristics were verified through DC measurement, and it was verified that switching characteristics of two different characteristics could be easily controlled only by adjusting a voltage. Multi-levels in various cases were confirmed by varying the amount of voltage that adjusts different characteristics, and the conductance quantization phenomenon was also confirmed within the reset section and pulse measurements. This MLC phenomenon was connected with pulse measurement to measure potentiation and depression, and it was possible to maximize MLC characteristics through voltage control of each segment. Including PPD and EPSC, through the measurement of STDP, the change in the conductance weight of the device was confirmed by imitating the synapse. In conclusion, the MLC characteristics of the device and the suitability of neuromorphic computing were successfully completed.

Availability of Data and Materials

All data generated or analysed during this study are included in this article.

References

Wang R, Yang J-Q, Mao J-Y et al (2020) Recent advances of volatile memristors: devices, mechanisms, and applications. Adv Intell Syst. https://doi.org/10.1002/aisy.202000055

Kim S, Kim H, Hwang S et al (2017) Analog synaptic behavior of a silicon nitride memristor. ACS Appl Mater Interfaces 9:40420–40427. https://doi.org/10.1021/acsami.7b11191

Ismail M, Abbas H, Sokolov A et al (2021) Emulating synaptic plasticity and resistive switching characteristics through amorphous Ta2O5 embedded layer for neuromorphic computing. Ceram Int 47:30764–30776. https://doi.org/10.1016/j.ceramint.2021.07.257

Li Q, Tao Q, Chen Y et al (2021) Low voltage and robust InSe memristor using van der Waals electrodes integration. Int J Extreme Manuf. https://doi.org/10.1088/2631-7990/ac2296

Ryu H, Kim S (2020) Self-rectifying resistive switching and short-term memory characteristics in Pt/HFO2/TaOx/TiN artificial synaptic device. Nanomaterials 10:2159. https://doi.org/10.3390/nano1011215

Park M, Kang M, Kim S (2021) Pulse frequency dependent synaptic characteristics in Ta/SiN/Si memristor device for neuromorphic system. J Alloys Compd 882:160760. https://doi.org/10.1016/j.jallcom.2021.160760

Ryu JH, Mahata C, Kim S (2021) Long-term and short-term plasticity of Ta2O5/HfO2 memristor for hardware neuromorphic application. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.156675

Kim D, Kim S, Kim S (2021) Logic-in-memory application of CMOS compatible silicon nitride memristor. Chaos Solitons Fract 153:11154. https://doi.org/10.1016/j.chaos.2021.111540

Lin KL, Hou TH, Shieh J et al (2011) Electrode dependence of filament formation in HfO2 resistive-switching memory. J Appl Phys 109:084104. https://doi.org/10.1063/1.3567915

Rodriguez-Fernandez A, Aldana S, Campabadal F et al (2017) Resistive switching with self-rectifying tunability and influence of the oxide layer thickness in Ni/HfO2/n+-Si RRAM devices. IEEE Trans Electron Devices 64:3159–3166. https://doi.org/10.1109/TED.2017.2717497

Hu G, An H, Xi J et al (2021) A ZnO micro/nanowire-based photonic synapse with piezo-phototronic modulation. Nano Energy 89:106282. https://doi.org/10.1016/j.nanoen.2021.106282

Khan SA, Lee GH, Mahata C et al (2021) Bipolar and complementary resistive switching characteristics and neuromorphic system simulation in a Pt/ZnO/TiN synaptic device. Nanomaterials 11:315. https://doi.org/10.3390/nano11020315

Sun J, Tan JB, Chen T (2020) Investigation of electrical noise signal triggered resistive switching and its implications. IEEE Trans Electron Devices 67:4178–4184. https://doi.org/10.1109/TED.2020.3014841

Shin J, Kang M, Kim S (2021) Gradual conductance modulation of Ti/WOx/Pt memristor with self-rectification for a neuromorphic system. Appl Phys Lett 119:012102. https://doi.org/10.1063/5.0053478

Chen ZX, Fang Z, Wang Y et al (2014) Impact of Ni concentration on the performance of Ni silicide/HfO2/TiN resistive RAM (RRAM) cells. J Electron Mater 43:4193–4198. https://doi.org/10.1007/s11664-014-3309-9

Luo Q, Xu X, Gong T et al (2018) 8-Layers 3D vertical RRAM with excellent scalability towards storage class memory applications. In: Technical digest—international electron devices meeting, IEDM

Yu S, Chen HY, Gao B et al (2013) HfOx-based vertical resistive switching random access memory suitable for bit-cost-effective three-dimensional cross-point architecture. ACS Nano 7:2320–2325. https://doi.org/10.1021/nn305510u

Al-Haddad A, Wang C, Qi H et al (2016) Highly-ordered 3D vertical resistive switching memory arrays with ultralow power consumption and ultrahigh density. ACS Appl Mater Interfaces 8:23348–23355. https://doi.org/10.1021/acsami.6b05424

Yu M, Cai Y, Wang Z et al (2016) Novel vertical 3D structure of TaOx-based RRAM with self-localized switching region by sidewall electrode oxidation. Sci Rep 6:1–10. https://doi.org/10.1038/srep21020

Jeong DS, Thomas R, Katiyar RS et al (2012) Emerging memories: resistive switching mechanisms and current status. Rep Prog Phys 75:076502

Lanza M, Wong HSP, Pop E et al (2019) Recommended methods to study resistive switching devices. Adv Electron Mater 5:1800143

Waser R, Aono M (2007) Nanoionics-based resistive switching memories. Nat Mater 6:833–840. https://doi.org/10.1038/nmat2023

Sawa A (2008) Resistive switching in transition metal oxides. Mater Today 11:28–36

Yu S (2014) Overview of resistive switching memory (RRAM) switching mechanism and device modeling. In: Proceedings—IEEE international symposium on circuits and systems

Li YT, Long SB, Liu Q et al (2011) An overview of resistive random access memory devices. Chin Sci Bull 56:3072–3078

Choi J, Kim S (2020) Improved stability and controllability in ZrN-based resistive memory device by inserting TiO2 layer. Micromachines 11:905. https://doi.org/10.3390/mi11100905

Kim S, Chen J, Chen YC et al (2019) Neuronal dynamics in HfOx/AlOy-based homeothermic synaptic memristors with low-power and homogeneous resistive switching. Nanoscale 11:237–245. https://doi.org/10.1039/c8nr06694a

Zhang K, Sun K, Wang F et al (2015) Ultra-low power Ni/HfO2/TiOx/TiN resistive random access memory with sub-30-nA reset current. IEEE Electron Device Lett 36:1018–1020. https://doi.org/10.1109/LED.2015.2464239

Sun QQ, Gu JJ, Chen L et al (2011) Controllable filament with electric field engineering for resistive switching uniformity. IEEE Electron Device Lett 32:1167–1169. https://doi.org/10.1109/LED.2011.2159770

Kwon O, Kim Y, Kang M, Kim S (2021) Comparison of synaptic properties considering dopant concentration and device operation polarity in Cu/SiN/SiO2/p-Si devices for neuromorphic system. Appl Surf Sci 563:150101. https://doi.org/10.1016/j.apsusc.2021.150101

Vishwanath SK, Woo H, Jeon S (2018) Enhancement of resistive switching properties in Al2O3 bilayer-based atomic switches: Multilevel resistive switching. Nanotechnology 29:235202. https://doi.org/10.1088/1361-6528/aab6a3

Chen L, Gou HY, Sun QQ et al (2011) Enhancement of resistive switching characteristics in Al2O3-based RRAM with embedded ruthenium nanocrystals. IEEE Electron Device Lett 32:794–796. https://doi.org/10.1109/LED.2011.2125774

Chen L, Xu Y, Sun QQ et al (2010) Highly uniform bipolar resistive switching with Al2O3 buffer layer in robust NbAlO-based RRAM. IEEE Electron Device Lett 31:356–358. https://doi.org/10.1109/LED.2010.2041183

Kim S, Park BG (2016) Nonlinear and multilevel resistive switching memory in Ni/Si3N4/Al2O3/TiN structures. Appl Phys Lett 108:212103. https://doi.org/10.1063/1.4952719

Chen C, Pan F, Wang ZS et al (2012) Bipolar resistive switching with self-rectifying effects in Al/ZnO/Si structure. J Appl Phys 111:013702. https://doi.org/10.1063/1.3672811

Wang Z, Yaegashi O, Sakaue H et al (2003) Suppression of native oxide growth in sputtered TaN films and its application to Cu electroless plating. J Appl Phys 94:4697–4701. https://doi.org/10.1063/1.1609644

Zhou Q, Zhai J (2014) Study of the bipolar resistive-switching behaviors in Pt/GdOx/TaNx structure for RRAM application. Physica Status Solidi A Appl Mater Sci 211:173–179. https://doi.org/10.1002/pssa.201330098

Zhou P, Yin M, Wan HJ et al (2009) Role of TaON interface for CuxO resistive switching memory based on a combined model. Appl Phys Lett 94:053510. https://doi.org/10.1063/1.3078824

Fang R-C, Sun Q-Q, Zhou P et al (2013) High-performance bilayer flexible resistive random access memory based on low-temperature thermal atomic layer deposition. Nanoscale Res Lett 8:1–7. https://doi.org/10.1186/1556-276x-8-92

Zhou J, dan Nie D, Jin XB, Xiao W (2020) Controllable nitridation of Ta2O5 in molten salts for enhanced photocatalysis. Int J Miner Metall Mater 27:1703–1710. https://doi.org/10.1007/s12613-020-2050-z

Misha SH, Tamanna N, Woo J et al (2015) Effect of nitrogen doping on variability of TaOx-RRAM for low-power 3-bit MLC applications. ECS Solid State Lett 4:P25–P28. https://doi.org/10.1149/2.0011504ssl

Cristea D, Cunha L, Gabor C et al (2019) Tantalum oxynitride thin films: assessment of the photocatalytic efficiency and antimicrobial capacity. Nanomaterials 9:476. https://doi.org/10.3390/nano9030476

Ismail M, Mahata C, Kim S (2022) Forming-free Pt/Al2O3/HfO2/HfAlOx/TiN memristor with controllable multilevel resistive switching and neuromorphic characteristics for artificial synapse. J Alloys Compd 892:162141. https://doi.org/10.1016/j.jallcom.2021.162141

Ryu H, Kim S (2021) Gradually modified conductance in the self-compliance region of an atomic-layer-deposited Pt/TiO2/HfAlOx/TiN rram device. Metals 11:1199. https://doi.org/10.3390/met11081199

Chen MC, Chang TC, Chiu YC et al (2013) The resistive switching characteristics in TaON films for nonvolatile memory applications. Thin Solid Films 528:224–228. https://doi.org/10.1016/j.tsf.2012.09.081

Ismail M, Abbas H, Mahata C et al (2022) Optimizing the thickness of Ta2O5 interfacial barrier layer to limit the oxidization of Ta ohmic interface and ZrO2 switching layer for multilevel data storage. J Mater Sci Technol 106:98–107. https://doi.org/10.1016/j.jmst.2021.08.012

Lin J, Wang S, Liu H (2021) Multi-level switching of al-doped HfO2 RRAM with a single voltage amplitude set pulse. Electronics (Switzerland) 10:731. https://doi.org/10.3390/electronics10060731

Wu J, Ye C, Zhang J et al (2016) Multilevel characteristics for bipolar resistive random access memory based on hafnium doped SiO2 switching layer. Mater Sci Semicond Process 43:144–148. https://doi.org/10.1016/j.mssp.2015.12.012

Li Y, Long S, Liu Y et al (2015) Conductance quantization in resistive random access memory. Nanoscale Res Lett 10:1–30

Celano U, Goux L, Belmonte A et al (2015) Understanding the dual nature of the filament dissolution in conductive bridging devices. J Phys Chem Lett 6:1919–1924. https://doi.org/10.1021/acs.jpclett.5b00633

Sharath SU, Vogel S, Molina-Luna L et al (2017) Control of switching modes and conductance quantization in oxygen engineered HfOx based memristive devices. Adv Funct Mater 27:1700432. https://doi.org/10.1002/adfm.201700432

Park J, Lee S, Lee K, Kim S (2021) Conductance quantization behavior in pt/sin/tan rram device for multilevel cell. Metals 11:1918. https://doi.org/10.3390/met11121918

Sun Y, Wen D (2018) Conductance quantization in nonvolatile resistive switching memory based on the polymer composite of zinc oxide nanoparticles. J Phys Chem C 122:10582–10591. https://doi.org/10.1021/acs.jpcc.8b01120

Gao S, Zeng F, Chen C et al (2013) Conductance quantization in a Ag filament-based polymer resistive memory. Nanotechnology 24:335201. https://doi.org/10.1088/0957-4484/24/33/335201

Zhu X, Su W, Liu Y et al (2012) Observation of conductance quantization in oxide-based resistive switching memory. Adv Mater 24:3941–3946. https://doi.org/10.1002/adma.201201506

Mehonic A, Vrajitoarea A, Cueff S et al (2013) Quantum conductance in silicon oxide resistive memory devices. Sci Rep 3:1–8. https://doi.org/10.1038/srep02708

Gao S, Chen C, Zhai Z et al (2014) Resistive switching and conductance quantization in Ag/SiO2/indium tin oxide resistive memories. Appl Phys Lett 105:063504. https://doi.org/10.1063/1.4893277

Long S, Lian X, Cagli C et al (2013) Quantum-size effects in hafnium-oxide resistive switching. Appl Phys Lett 102:183505. https://doi.org/10.1063/1.4802265

Tsuruoka T, Hasegawa T, Terabe K, Aono M (2012) Conductance quantization and synaptic behavior in a Ta2O5-based atomic switch. Nanotechnology 23:435705. https://doi.org/10.1088/0957-4484/23/43/435705

Chen C, Gao S, Zeng F et al (2013) Conductance quantization in oxygen-anion-migration-based resistive switching memory devices. Appl Phys Lett 103:043510. https://doi.org/10.1063/1.4816747

Lv H, Xu X, Sun P et al (2015) Atomic view of filament growth in electrochemical memristive elements. Sci Rep 5:1–8. https://doi.org/10.1038/srep13311

Milano G, Aono M, Boarino L et al (2022) Quantum conductance in memristive devices: fundamentals, developments, and applications. Adv Mater. https://doi.org/10.1002/adma.202201248

Zhao X, Xu J, Xie D et al (2021) Natural acidic polysaccharide-based memristors for transient electronics: highly controllable quantized conductance for integrated memory and nonvolatile logic applications. Adv Mater 33:1–10. https://doi.org/10.1002/adma.202104023

Banerjee W, Hwang H (2019) Quantized conduction device with 6-bit storage based on electrically controllable break junctions. Adv Electron Mater 5:1–10. https://doi.org/10.1002/aelm.201900744

Strukov DB, Kohlstedt H (2012) Resistive switching phenomena in thin films: Materials, devices, and applications. MRS Bull 37:108–114

Zhang SR, Zhou L, Mao JY et al (2019) Artificial synapse emulated by charge trapping-based resistive switching device. Adv Mater Technol 4:1800342. https://doi.org/10.1002/admt.201800342

Rahmani MK, Ismail M, Mahata C, Kim S (2020) Effect of interlayer on resistive switching properties of SnO2-based memristor for synaptic application. Results Phys 18:103325. https://doi.org/10.1016/j.rinp.2020.103325

Park J, Ryu H, Kim S (2021) Nonideal resistive and synaptic characteristics in Ag/ZnO/TiN device for neuromorphic system. Sci Rep 11:1–7. https://doi.org/10.1038/s41598-021-96197-8

Cho H, Kim S (2020) Enhancing short-term plasticity by inserting a thin TiO2 layer in WOx-based resistive switching memory. Coatings 10:908. https://doi.org/10.3390/COATINGS10090908

Ismail M, Mahata C, Kwon O, Kim S (2022) Neuromorphic synapses with high switching uniformity and multilevel memory storage enabled through a Hf-Al-O alloy for artificial intelligence. ACS Appl Electron Mater. https://doi.org/10.1021/acsaelm.2c00023

Lee Y, Mahata C, Kang M, Kim S (2021) Short-term and long-term synaptic plasticity in Ag/HfO2/SiO2/Si stack by controlling conducting filament strength. Appl Surf Sci 565:150563. https://doi.org/10.1016/j.apsusc.2021.150563

Feng G, Jiang J, Zhao Y et al (2020) A sub-10 nm vertical organic/inorganic hybrid transistor for pain-perceptual and sensitization-regulated nociceptor emulation. Adv Mater 32:1–11. https://doi.org/10.1002/adma.201906171

Li Y, Yin K, Diao Y et al (2022) A biopolymer-gated ionotronic junctionless oxide transistor array for spatiotemporal pain-perception emulation in nociceptor network. Nanoscale 14:2316–2326. https://doi.org/10.1039/d1nr07896h

Jiang J, Hu W, Xie D et al (2019) 2D electric-double-layer phototransistor for photoelectronic and spatiotemporal hybrid neuromorphic integration. Nanoscale 11:1360–1369. https://doi.org/10.1039/c8nr07133k

Shen Z, Zhao C, Qi Y et al (2020) Advances of RRAM devices: Resistive switching mechanisms, materials and bionic synaptic application. Nanomaterials 10:1437

Lu K, Li Y, He WF et al (2018) Diverse spike-timing-dependent plasticity based on multilevel HfOx memristor for neuromorphic computing. Appl Phys A Mater Sci Process 124:1–9. https://doi.org/10.1007/s00339-018-1847-3

Acknowledgements

Not applicable.

Funding

This research was supported in part by National R&D Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (2021K1A3A1A49098073) and in part by Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea Government (MOTIE) under Grant 20224000000020.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing interests

The authors declare they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, Y., Park, J., Chung, D. et al. Multi-level Cells and Quantized Conductance Characteristics of Al2O3-Based RRAM Device for Neuromorphic System. Nanoscale Res Lett 17, 84 (2022). https://doi.org/10.1186/s11671-022-03722-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-022-03722-3