Abstract

We present the molecular beam epitaxy fabrication and optical properties of complex GaAs nanostructures by droplet epitaxy: concentric triple quantum rings. A significant difference was found between the volumes of the original droplets and the final GaAs structures. By means of atomic force microscopy and photoluminescence spectroscopy, we found that a thin GaAs quantum well-like layer is developed all over the substrate during the growth interruption times, caused by the migration of Ga in a low As background.

Similar content being viewed by others

Introduction

The fabrication of semiconductor quantum nanostructures based on self-assembly has deeply attracted the research community because of the interest in fundamental physics and the potential applications of these systems as building blocks for novel devices and quantum information technologies [1–3]. In particular, quantum rings, a special class of semiconductor nanostructures, have been investigated since they manifest a quantum-interference phenomenon, known as the Aharonov–Bohm (AB) effect [4], and have also been applied for the fabrication of optoelectronic devices [5–7]. Therefore, the ability in the production of quantum ring systems has a great relevance in the nanotechnology field. During the last 15 years, molecular beam epitaxy (MBE) has been successfully employed for the fabrication of semiconductor nanoscopic rings, without the use of any lithographic step [8–11]. Based on droplet epitaxy (DE) [12, 13], we recently demonstrated the fabrication and discussed the growth of GaAs concentric multiple quantum rings [14]. The innovation in our growth protocol, compared with the standard DE, resides in the multiple steps used for the droplets crystallization. Normally the crystallization of nanometer-sized Ga droplets, automatically formed at the substrate surface after irradiation of Ga, has been achieved by supplying an As flux until the complete consumption of Ga atoms. On the contrary, we introduced many pulsed arsenization steps at different substrate temperatures, opening the possibility for the fabrication of more complex GaAs nanostructures. The partial crystallization of the available Ga inside the droplets allows changes in the subsequent As supply condition (arsenic BEP and substrate temperatures), adding an important degree of freedom in the fabrication technique. Here, we will discuss the formation of concentric triple quantum rings (CTQRs), describing the morphological features by means of atomic force microscopy (AFM) analysis, and we will show the optical properties of the system, investigated by photoluminescence (PL) spectroscopy. Interestingly, we found that the volume of the final GaAs nanostructure is much lower than the expected value, estimated from the initial amount of supplied Ga. This discrepancy is justified in terms of Ga atoms diffusion from the droplets to high distance onto the substrate surface during the growth interruption steps of the procedure. This explanation is supported by the presence of an additional peak in the PL spectra consistent with the emission of a quantum well-like thin layer of GaAs formed all over the substrate.

Experimental Details

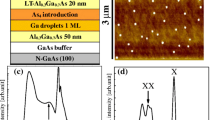

The growth experiments were performed in a conventional GEN II MBE system using epi-ready GaAs (001) substrates. After the growth of a 500-nm-thick GaAs buffer layer and of a 200-nm-thick Al0.3Ga0.7As barrier layer at 580°C, the substrate temperature was decreased to 350°C and the As valve closed until the background pressure was below 1 × 10−9 Torr. At the same temperature, a Ga molecular beam equivalent to the formation of 10 ML of GaAs in the presence of As was supplied to the substrate surface, for the droplets formation. After that, the substrate temperature was decreased to 250°C and an As BEP of 8 × 10−7 Torr was supplied for 20 s for the partial crystallization of the original droplets into GaAs. Finally, the substrate temperature was increased to 300°C and the sample surface was irradiated by the same As BEP (8 × 10−7 Torr) for 20 min, to ensure the complete reaction of metallic Ga with As. It is worth mentioning that a growth interruption time of around 1 h was used to reach the thermal stability of the sample after each change of the substrate temperature. After the growth, the samples were taken out of the chamber for the morphological analysis by AFM and optical investigation by PL. Three samples were prepared: Sample A by stopping the growth just after the Ga supply; Sample B after completely performing the described procedure; and Sample C by burying the GaAs nanostructure in Al0.3Ga0.7As and annealing at 650°C in As atmosphere for the optical measurements. Photoluminescence spectra of Sample C were measured at T = 15 K using a green laser (λexc = 532 nm) as excitation source with a power density P exc = 10 W/cm2 and recorded by a Peltier-cooled CCD camera.

Results and Discussion

In Fig. 1a and 1b, we show the AFM images of Sample A, where the growth was stopped just after the deposition of Ga and Sample B, where the entire procedure was performed. The Ga supply clearly resulted in the formation of nanometer-sized, nearly hemispherical Ga droplets. Their average diameter and height were around 80 and 35 nm, respectively, while the density was estimated to be around 8 × 108 cm−2. At the end of the procedure, clear CTQRs structures with good rotational symmetry appeared, with inner, middle and outer ring diameters of around 80, 140 and 210 nm, respectively, while heights were around 7 nm for the inner rings, 4 nm for middle rings and 3 nm for the outer rings. These structures showed an elongation of around 11% along the [0–11] direction, which might be due to the anisotropic diffusion of Ga on GaAs (001) surface [15]. It is worth noticing that the inner rings showed nearly the same diameter to that of the original Ga droplet and that the density of the final GaAs structures was equal to that of the original droplets, confirming that all Ga droplets transformed into GaAs triple rings at the end of the procedure. As already discussed in Ref. [14], the formation of the inner rings comes from the crystallization of the droplets edge, thus explaining the identity between droplets and inner rings diameters. On the contrary, middle and outer rings appear caused by the subsequent As supplies, as a result of the interplay between As adsorption and Ga migration from the droplets. Fig. 1c shows the cross-sectional height profile for Sample A (black line) and B (red line) obtained from the AFM images. It is important to point out that there is a significant difference between the number of Ga atoms initially supplied, corresponding to the equivalent amount of 10 MLs, and the number of Ga atoms, evaluated to be equivalent to around 3–4 MLs, inside the final structure. This difference suggests that only a fraction of the initially supplied Ga atoms effectively concur to the formation of the 3D nanostructures, while the other part, estimated to be around 6–7 MLs, might be consumed in another process. The reason for this discrepancy might be found considering our experimental procedure for the formation of CTQRs. As mentioned before, the three main steps of the growth are performed at different temperatures: 350°C for the droplets formation, 250°C for the first As supply and 300°C for the second As supply. To establish the thermal equilibrium of the substrate, we observed 1 h growth interruption times after each change of the substrate temperature. During these waiting times, a portion of the Ga atoms stored in the droplets might be consumed to form a 2D GaAs thin layer all over the substrate. We believe this phenomenon to be caused by a slow 2D crystallization of Ga atoms diffusing from the droplets, even in the absence of an intentional As supply. Indeed, an As background pressure of around 1 × 10−9 Torr is present during the whole procedure, thus providing the unintentional As pressure needed for the partial crystallization of Ga atoms. As we recently found in similar systems, a slow GaAs crystallization all over the substrate might take place in case of very low As supply to the Ga droplets [16]. In these conditions of very low As flux, the surface mobility of Ga atoms is so large that an uniform layer of GaAs might be formed all over the substrate surface. In a capped sample, embedded in an Al0.3Ga0.7As barrier, this layer can act as a quantum well, confining carriers and eventually being optically active. In order to check the optical quality of CTQRs and to confirm the presence of a thin quantum well-like GaAs layer all over the substrate coming from the unintentional crystallization of a certain amount of Ga atoms during the procedure, we performed PL investigations. The same structure of Sample B was therefore grown on another sample (Sample C) and embedded in an Al0.3Ga0.7As barrier layer. Figure 2 shows the PL spectra of Sample C excited at 15 K by a green laser (λexc = 532 nm) with a power density P exc = 10 W/cm2 and recorded by a Peltier-cooled CCD camera. In the region where the emission from quantum-confined GaAs structures is expected, two peaks, respectively named Peak 1 at 1.55 eV and Peak 2 at 1.76 eV, appeared. A calculation on the electronic structure for the CTQRs was performed in the framework of the effective mass approximation [17–20], allowing us to attribute Peak 1 to the emission of the localized states within the CTQRs. On the other hand, on the basis of the same theoretical predictions, Peak 2 can be safely assigned to a 2D GaAs quantum well (QW), which appeared all over the substrate during the procedure. As already discussed, only a fraction of the total supplied Ga is effectively crystallized to form the Triple Rings, while the remaining 6–7 MLs of Ga atoms concur to the formation of a 2D layer of GaAs, as described above. Within the effective mass approximation, a 6–7 MLs-thick GaAs QW is expected to emit at 1.76 eV, in excellent agreement with the observed Peak 2 feature. We believe that the presence of this 2D layer might be a general feature in the samples grown with our multiple steps DE, by observing growth interruption times.

Conclusion

We presented the growth and the optical properties of GaAs CTQRs fabricated by DE. At the end of our multistep procedure, Ga droplets are transformed into these complex nanostructures. We found a significant difference in the volume of the final structure compared to the initially supplied amount of Ga. We explain this discrepancy in terms of Ga diffusion all over the substrate during the growth interruption steps of the experiments, caused by the residual As partial pressure in the chamber. This picture is strongly supported by the presence of a high-energy peak in the PL, which is consistent with the presence of a thin GaAs quantum well on the substrate.

References

Michler P, Kiraz A, Becher C, Schoenfeld WV, Petroff PM, Zhang L, Hu E, Imamoglu A: Science. 2000, 290: 2282. COI number [1:CAS:528:DC%2BD3cXptFSnu7s%3D]; Bibcode number [2000Sci...290.2282M] COI number [1:CAS:528:DC%2BD3cXptFSnu7s%3D]; Bibcode number [2000Sci...290.2282M] 10.1126/science.290.5500.2282

Li X, Wu Y, Steel D, Gammon D, Stievater TH, Katzer DS, Park D, Piermarocchi C, Sham LJ: Science. 2003, 301: 809. COI number [1:CAS:528:DC%2BD3sXmtVGqsrc%3D]; Bibcode number [2003Sci...301..809L] COI number [1:CAS:528:DC%2BD3sXmtVGqsrc%3D]; Bibcode number [2003Sci...301..809L] 10.1126/science.1083800

Solinas P, Zanardi P, Zanghi N, Rossi F: Phys. Rev. B. 2003, 67: 121307. Bibcode number [2003PhRvB..67l1307S] Bibcode number [2003PhRvB..67l1307S] 10.1103/PhysRevB.67.121307

Aharonov Y, Bohm D: Phys. Rev.. 1959, 115: 485. Bibcode number [1959PhRv..115..485A] Bibcode number [1959PhRv..115..485A] 10.1103/PhysRev.115.485

Mano T, Kuroda T, Yamagiwa M, Kido G, Sakoda K, Koguchi N: Appl. Phys. Lett.. 2006, 89: 183102. Bibcode number [2006ApPhL..89r3102M] Bibcode number [2006ApPhL..89r3102M] 10.1063/1.2372448

Wu J, Li Z, Shao D, Manasreh MO, Kunets VP, Wang ZM, Salamo GJ, Weaver BD: Appl. Phys. Lett.. 2009, 94: 171102. Bibcode number [2009ApPhL..94q1102W] Bibcode number [2009ApPhL..94q1102W] 10.1063/1.3126644

Wu J, Shao D, Li Z, Manasreh MO, Kunets V, Wang Z, Salamo G: Appl. Phys. Lett.. 2009, 95: 071908. Bibcode number [2009ApPhL..95g1908W] Bibcode number [2009ApPhL..95g1908W] 10.1063/1.3211971

Garcia JM, Medeiros-Ribeiro G, Schmidt K, Ngo T, Feng J, Lorke A, Kotthaus J, Petroff P: Appl. Phys. Lett.. 1997, 71: 2014. COI number [1:CAS:528:DyaK2sXmsFOit70%3D]; Bibcode number [1997ApPhL..71.2014G] COI number [1:CAS:528:DyaK2sXmsFOit70%3D]; Bibcode number [1997ApPhL..71.2014G] 10.1063/1.119772

Granados D, Garcia JM: Appl. Phys. Lett.. 2003, 82: 2401. COI number [1:CAS:528:DC%2BD3sXivFamu78%3D]; Bibcode number [2003ApPhL..82.2401G] COI number [1:CAS:528:DC%2BD3sXivFamu78%3D]; Bibcode number [2003ApPhL..82.2401G] 10.1063/1.1566799

Watanabe K, Koguchi N, Gotoh Y: Jpn. J. Appl. Phys.. 2000, 39: L79. COI number [1:CAS:528:DC%2BD3cXhtlSqt7w%3D]; Bibcode number [2000JaJAP..39...79W] COI number [1:CAS:528:DC%2BD3cXhtlSqt7w%3D]; Bibcode number [2000JaJAP..39...79W] 10.1143/JJAP.39.L79

Mano T, Koguchi N: J. Cryst. Growth. 2005, 278: 108. COI number [1:CAS:528:DC%2BD2MXjsVelsro%3D]; Bibcode number [2005JCrGr.278..108M] COI number [1:CAS:528:DC%2BD2MXjsVelsro%3D]; Bibcode number [2005JCrGr.278..108M] 10.1016/j.jcrysgro.2004.12.119

Koguchi N, Takahashi S, Chikyow T: J. Cryst. Growth. 1991, 111: 688. COI number [1:CAS:528:DyaK3MXkvVamsro%3D]; Bibcode number [1991JCrGr.111..688K] COI number [1:CAS:528:DyaK3MXkvVamsro%3D]; Bibcode number [1991JCrGr.111..688K] 10.1016/0022-0248(91)91064-H

Koguchi N, Ishige K: Jpn. J. Appl. Phys.. 1993, 32: 2052. COI number [1:CAS:528:DyaK3sXks1Sjsb0%3D]; Bibcode number [1993JaJAP..32.2052K] COI number [1:CAS:528:DyaK3sXks1Sjsb0%3D]; Bibcode number [1993JaJAP..32.2052K] 10.1143/JJAP.32.2052

Somaschini C, Bietti S, Koguchi N, Sanguinetti S: Nano. Lett.. 2009, 9: 3419. COI number [1:CAS:528:DC%2BD1MXhtFGlsLjE]; Bibcode number [2009NanoL...9.3419S] COI number [1:CAS:528:DC%2BD1MXhtFGlsLjE]; Bibcode number [2009NanoL...9.3419S] 10.1021/nl901493f

Ohta K, Kojima T, Nakagawa T: J. Cryst. Growth. 1989, 95: 71. COI number [1:CAS:528:DyaL1MXitF2ls7g%3D]; Bibcode number [1989JCrGr..95...71O] COI number [1:CAS:528:DyaL1MXitF2ls7g%3D]; Bibcode number [1989JCrGr..95...71O] 10.1016/0022-0248(89)90354-0

Somaschini C, Bietti S, Sanguinetti S, Koguchi N, Fedorov A: Nanotechnology. 2010, 21: 125601. COI number [1:STN:280:DC%2BC3c7lvVahuw%3D%3D]; Bibcode number [2010Nanot..21l5601S] COI number [1:STN:280:DC%2BC3c7lvVahuw%3D%3D]; Bibcode number [2010Nanot..21l5601S] 10.1088/0957-4484/21/12/125601

Marzin JY, Bastard G: Solid.State Commun.. 1994, 92: 437. COI number [1:CAS:528:DyaK2MXhsVShu7Y%3D]; Bibcode number [1994SSCom..92..437M] COI number [1:CAS:528:DyaK2MXhsVShu7Y%3D]; Bibcode number [1994SSCom..92..437M] 10.1016/0038-1098(94)90524-X

Pavesi L, Guzzi M: J. Appl. Phys.. 1994, 75: 4779. COI number [1:CAS:528:DyaK2cXkvFCmsbo%3D]; Bibcode number [1994JAP....75.4779P] COI number [1:CAS:528:DyaK2cXkvFCmsbo%3D]; Bibcode number [1994JAP....75.4779P] 10.1063/1.355769

Califano M, Harrison P: Phys. Rev. B. 2000, 61: 10959. COI number [1:CAS:528:DC%2BD3cXis1amsb8%3D]; Bibcode number [2000PhRvB..6110959C] COI number [1:CAS:528:DC%2BD3cXis1amsb8%3D]; Bibcode number [2000PhRvB..6110959C] 10.1103/PhysRevB.61.10959

Sanguinetti S, Watanabe K, Kuroda T, Minami F, Gotoh Y, Koguchi N: J. Cryst. Growth. 2002, 242: 321. COI number [1:CAS:528:DC%2BD38XkvFGqtLo%3D]; Bibcode number [2002JCrGr.242..321S] COI number [1:CAS:528:DC%2BD38XkvFGqtLo%3D]; Bibcode number [2002JCrGr.242..321S] 10.1016/S0022-0248(02)01434-3

Acknowledgments

This work was partially supported by the CARIPLO Foundation (prj. QUADIS2–no. 2008-3186).

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Somaschini, C., Bietti, S., Fedorov, A. et al. Growth Interruption Effect on the Fabrication of GaAs Concentric Multiple Rings by Droplet Epitaxy. Nanoscale Res Lett 5, 1897 (2010). https://doi.org/10.1007/s11671-010-9752-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11671-010-9752-5