Abstract

In this article, a new method is used to fabricate a high-performance triboelectric nanogenerator (TENG), which is convenient and cost-effective. A polyformaldehyde (POM) film with novel structures is prepared through electrospinning and is combined with a polytetrafluoroethylene (PTFE) film to assemble micro-nano structured TENG. The short-circuit current (I s) and open-circuit voltage (V o) of the TENG are up to 0.4343 mA and 236.8 V, respectively, and no significant change is observed by applying different frequencies of external impact forces from 1 to 10 Hz. Finally, we successfully drive an electrochromic device (ECD) directly using TENG within just 2 min for the first time.

Similar content being viewed by others

Background

Energy’s critical importance in social development and people’s lives is now universally recognized. A lot of technologies, such as photoelectric [1], pyroelectric [2], magnetoelectric [3], and piezoelectric [4], have been invented to collect energy in the environment, for example, in the form of light, heat, and motion. In recent years, triboelectricity is applied to a new type of generator named triboelectric nanogenerator (TENG) to harvest mechanical energy [5–9]. The TENG is efficient, flexible, and easy to fabricate, so it has aroused intense scholarly interest since its advent.

Typically, TENG is multilayered, consisting of friction layers and electrode layers (Fig. 1). It mainly utilizes the static charges generated during tribological process to induce electricity between the electrodes. Compared to the untreated friction surface, the micro and nano friction surface improved the output of TENG as it increased the area of friction layers and resulted in the generation of more electrostatic charges on the friction layers [10, 11]. Various methods have been tried to modify the friction surface such as ion beam etching [12], silicon template [10], anodic aluminum oxide template [13], and synthesis and assembly of nanoparticles and nanowires [11, 14]. However, these methods are either complicated or costly. Electrospinning is one of the novel fiber fabrication techniques because it is easy to produce continuous polymer fibers with diameters ranging from several nanometers to micrometers [15–17]. Using electrospinning to prepare nanowire-based TENG simplifies the preparation process and reduces the cost [18].

In this article, we propose a facile method to fabricate high-output TENG by preparing a micro-nano structured polyformaldehyde (POM) film through electrospinning as one friction layer and utilizing a polytetrafluoroethylene (PTFE) film as the other, which not only simplifies the fabrication process but also enhances the electric output of TENG. The open-circuit voltage (V o) of our prototype TENG reaches 236.8 V, and the short-circuit current (I s) is up to 0.4343 mA. Such high output current makes it sufficient to drive a homemade electrochromic device (ECD) directly. For these obvious advantages, TENG has potential application in the area of electronics, health care, and other practical applications.

Methods

Preparation of POM Film

To prepare the solution for electrospinning, 0.8 g POM (Yunnan Yuntianhua Co., Ltd., China) was dissolved into 9.2 g hexafluoroisopropanol (Aladdin Industrial Inc., China) in a 10-mL glass sample bottle [19]. The process was conducted by a NEU nanofiber electrospinning unit (Kato Tech Co., Ltd., Japan). One copper plate collector covered by aluminum foil was located 15 cm away from the needle tip of the syringe and was grounded. A high direct current voltage of 18 kV was applied between the needle tip and the copper plate collector, and the volumetric flow rate of the polymer solution was 0.8 mL/h. All the experiments were done at room temperature with a relative humidity of 55 %. The electrospinning process was finished after 4 h. The electrospun POM film was dried in a vacuum oven at room temperature overnight to remove the residual solvent.

Fabrication of TENG

The typical fabrication process of TENG is depicted in Fig. 1. First, a thin layer of gold (100 nm) was deposited on two pieces of polyethylene terephthalate (PET) films (4 × 4 cm) (Dongguan Chang’an Chaoyuan Film Co., Ltd., China) by a sputter coater. Second, each PET film is adhered with a layer of double-sided adhesive tape on the gold side. Third, the PTFE film (4 × 4 cm) (Deqing Tonghe Plastics Research Institute, China) and electrospun POM film (4 × 4 cm) were respectively adhered onto the two arched PET films. Then, TENG was assembled by using adhesive tape to fix the two freshly prepared sheets along the straight sides with a width of 2 mm on each sheet.

Characterization and Measurement

The morphologies of the electrospun POM film and untreated PTFE film were investigated using a field emission scanning electron microscope (FE-SEM) (JSM-6700F, JEOL, Japan). The electric output of TENG was measured using a digital multimeter (34410A, Agilent Technologies, Inc., USA). The external impact forces were provided by a vibration exciter (Baofei Vibration Instrument Plant, China).

Results and Discussion

Working Mechanism of TENG

The working mechanism of TENG is illustrated in Fig. 2. In the initial state, each layer of TENG is electrically quasi-neutral. After applying external compressive force for the first time, the arched TENG is deformed. The top sheet contacts the bottom one, and friction takes place between the contact surfaces because of surface roughness in microscale. As a result, the friction surfaces carry opposite electrostatic charges which will not bleed off or be neutralized immediately since both the polymer films and air are insulative. When removing the external force, the TENG tends to recover to arched state and the friction surfaces move apart. Meanwhile, the electric potential between the two electrodes varies with the relative displacement of the oppositely charged friction surfaces. Thus, there will be current in the load circuit until establishing potential equilibrium between the two electrodes. Applying the external force again breaks the former equilibrium and causes a reverse current to establish a new potential equilibrium. The mechanism is similar to a previously reported TENG [12]. Frequently applying and removing the external forces lead to more friction and cause the friction surfaces to come close and draw apart repeatedly, synchronized with the variance of electric potential difference between the two electrodes. Thus, there will be alternating pulsed current in the load circuit of the TENG.

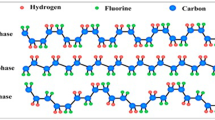

Triboelectric properties of friction materials have a great influence on the performance of TENG. In our work, two low-cost polymers with quite different triboelectric properties were used as friction surfaces of TENG: PTFE is most likely to be negatively charged, and POM is easy to be positively charged by triboelectrification [20].

Performance Analysis of TENG

In order to further increase the electric output of TENG, we prepared a micro-nano structured POM film since charges generated by friction are largely decided by the surface morphology of friction materials [21]. Utilizing electrospinning technology simplifies its preparation process, and the POM film with special structures is obtained through adjusting the electrospinning parameters. As shown in Fig. 3a, the POM fibers are randomly oriented with uniform diameters ranging from about 500 to 800 nm. Particularly, porous nanostructures are formed on the surface of the fibers. According to reported studies, rough surface with micro-nano structures and porous structures could enhance friction and increase contact area [10, 11, 22]. Thus, this novel micro-nano structure is supposed to enhance friction and to increase the electric output of TENG. In addition, the nanoscale cracks on the surface of the commercial PTFE film (Fig. 3b) are advantageous to the enhancement of friction. Consequently, more electrostatic charges will be generated and distributed on the surfaces of POM and PTFE after friction, which could help improve the performance of our TENG.

To investigate electric output of the micro-nano structured TENG, the V o and I s of the TENG under external impact forces of 400 N with a frequency of 5 Hz were measured, as shown in Fig. 3. It shows that the peak I s is 0.4343 mA and the peak V o is 236.8 V. The current density of 27.14 μA/cm2 is more than eight times higher than that of TENGs fabricated with PTFE and chemically modified titanium dioxide or surface-modified aluminum [14, 23], which demonstrates that our facile prepared TENG has high current output.

To further investigate the performance of TENG, we measured the electric output of TENG when it was connected to variable load resistances, ranging from 100 Ω to 100 MΩ, as shown in Fig. 4a. It is found that the current of the circuit decreases with the increasing of load resistance while the voltage has a reverse trend. The instantaneous power on the load will reach a maximum value of 57.18 mW at a load resistance of ~1 MΩ (see Additional file 1).

To study the influence of external force frequency on the electric output of TENG, further experiments under external impact forces of 400 N with frequencies of 1, 2, and 10 Hz were conducted (see Additional files 2 and 3). The output I s and V o and their standard deviation are plotted against frequency in Fig. 4b. It shows that the peak values under different frequencies of external impact forces are approximately the same, indicating that I s and V o are not affected by frequency. This phenomenon seems different with some articles [10, 24] reporting that the output of TENG varied with frequency. It is reasonable, however. According to a theoretical study [25],

where S and σ are the area and charge density of the friction surface, respectively, x is the distance of the top and bottom sheets, v is the rate of relative displacement of top and bottom sheets, d 0 is a constant related to thickness and relative dielectric constant of friction films, and ε 0 is the vacuum dielectric constant. It can be learnt that I s and V o have no direct correlation with frequency, but on the condition that frequency changes x or v, it may affect I s and V o indirectly. In this work, the experimental phenomenon is attributed to the way in which external forces were applied. Pulse signal was used to modulate the vibration exciter so that frequency did not cause much change to x and v. The detailed and precise influence still needs further research.

Moreover, V o of the TENG was measured after more than 5000 cycles to test the electric output stability (Fig. 5). It shows that there is no obvious decline (Fig. 5a). This might be due to the retained morphologies of POM and PTFE that have enhanced friction (Fig. 5b, c).

The high and stable electric output of the TENG implies its application to low-energy electronics, for example, ECD, which changes light transmission properties in response to voltage. We connected the TENG to a homemade ECD (1 × 1 cm) [26] through a rectifying circuit directly. By applying excitation impact forces of 10 Hz on the TENG continuously, the ECD switched from bleached state to colored state in 2 min (Fig. 6). This implies the promising potential of TENG in charging batteries and powering light-emitting diodes, liquid crystal displays, and some portable electronics.

Conclusions

In summary, we report a new method to fabricate high-output TENG with an easy and cost-effective approach, which contributes to the practical application of TENG. Our experimental results show that the electric output of the fabricated TENG is rather high as I s is up to 0.4343 mA and V o reaches 236.8 V, and the output current can be directly used to drive homemade ECD. The good performance and facile fabrication of TENG indicate its potential application in the area of electronics, health care, and other practical applications, especially portable electronics. By further optimizing structure, we believe that it will afford a broader range of applications.

Abbreviations

- ECD:

-

electrochromic device

- FE-SEM:

-

field emission scanning electron microscope

- POM:

-

polyformaldehyde

- PTFE:

-

polytetrafluoroethylene

- TENG:

-

triboelectric nanogenerator

References

Tang Z, George Z, Ma ZF, Bergqvist J, Tvingstedt K, Vandewal K, et al. Semi-transparent tandem organic solar cells with 90 % internal quantum efficiency. Adv Energy Mater. 2012;2(12):1467–76.

Leng Q, Chen L, Guo HY, Liu JL, Liu GL, Hu CG, et al. Harvesting heat energy from hot/cold water with a pyroelectric generator. J Mater Chem A. 2014;2(30):11940–7.

Zhou Y, Apo DJ, Priya S. Dual-phase self-biased magnetoelectric energy harvester. Appl Phys Lett. 2013;103(19):5.

Mao Y, Zhao P, McConohy G, Yang H, Tong Y, Wang X. Sponge-like piezoelectric polymer films for scalable and integratable nanogenerators and self-powered electronic systems. Adv Energy Mater. 2014;4(7):1301624.

Fan F-R, Tian Z-Q, Lin WZ. Flexible triboelectric generator. Nano Energy. 2012;1(2):328–34.

Wang S, Lin L, Xie Y, Jing Q, Niu S, Wang ZL. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013;13(5):2226–33.

Cheng G, Lin ZH, Du ZL, Wang ZL. Simultaneously harvesting electrostatic and mechanical energies from flowing water by a hybridized triboelectric nanogenerator. ACS Nano. 2014;8(2):1932–9.

Taghavi M, Mattoli V, Sadeghi A, Mazzolai B, Beccai L. A novel soft metal-polymer composite for multidirectional pressure energy harvesting. Adv Energy Mater. 2014;4:1400024.

Lee S, Ko W, Oh Y, Lee J, Baek G, Lee Y et al. Triboelectric energy harvester based on wearable textile platforms employing various surface morphologies. Nano Energy. 2015; doi:10.1016/j.nanoen.2015.01.009.

Zhang XS, Han MD, Wang RX, Zhu FY, Li ZH, Wang W, et al. Frequency-multiplication high-output triboelectric nanogenerator for sustainably powering biomedical microsystems. Nano Lett. 2013;13(3):1168–72.

Lin ZH, Zhu G, Zhou YS, Yang Y, Bai P, Chen J, et al. A self-powered triboelectric nanosensor for mercury ion detection. Angew Chem Int Ed Engl. 2013;52(19):5065–9.

Zhu G, Pan C, Guo W, Chen CY, Zhou Y, Yu R, et al. Triboelectric-generator-driven pulse electrodeposition for micropatterning. Nano Lett. 2012;12(9):4960–5.

Yang Y, Zhang H, Liu Y, Lin Z-H, Lee S, Lin Z, et al. Silicon-based hybrid energy cell for self-powered electrodegradation and personal electronics. ACS Nano. 2013;7(3):2808–13.

Lin Z-H, Xie Y, Yang Y, Wang S, Zhu G, Wang ZL. Enhanced triboelectric nanogenerators and triboelectric nanosensor using chemically modified TiO2 nanomaterials. ACS Nano. 2013;7(5):4554–60.

Cavaliere S, Subianto S, Savych I, Jones DJ, Roziere J. Electrospinning: designed architectures for energy conversion and storage devices. Energy Environ Sci. 2011;4(12):4761–85.

Luo CJ, Stoyanov SD, Stride E, Pelan E, Edirisinghe M. Electrospinning versus fibre production methods: from specifics to technological convergence. Chem Soc Rev. 2012;41(13):4708–35.

Ren G, Cai F, Li B, Zheng J, Xu C. Flexible pressure sensor based on a poly(VDF-TrFE) nanofiber web. Macromol Mater Eng. 2013;298(5):541–6.

Zheng Y, Cheng L, Yuan M, Wang Z, Zhang L, Qin Y, et al. Electrospun nanowire-based triboelectric nanogenerator and its application on the full self-powered UV detector. Nanoscale. 2014;6:7842–6.

Kongkhlang T, Kotaki M, Kousaka Y, Umemura T, Nakaya D, Chirachanchai S. Electrospun polyoxymethylene: spinning conditions and its consequent nanoporous nanofiber. Macromolecules. 2008;41(13):4746–52.

Diaz AF, Felix-Navarro RM. A semi-quantitative tribo-electric series for polymeric materials: the influence of chemical structure and properties. J Electrostat. 2004;62(4):277–90.

Baytekin HT, Patashinski AZ, Branicki M, Baytekin B, Soh S, Grzybowski BA. The mosaic of surface charge in contact electrification. Science. 2011;333(6040):308–12.

Lee KY, Chun J, Lee JH, Kim KN, Kang NR, Kim JY, et al. Hydrophobic sponge structure-based triboelectric nanogenerator. Adv Mater. 2014;26(29):5037–42.

Chen J, Zhu G, Yang W, Jing Q, Bai P, et al. Harmonic-resonator-based triboelectric nanogenerator as a sustainable power source and a self-powered active vibration sensor. Adv Mater. 2013;25(42):6094–9.

Wang S, Lin L, Wang ZL. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Lett. 2012;12(12):6339–46.

Niu S, Wang S, Lin L, Liu Y, Zhou YS, Hu Y, et al. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ Sci. 2013;6(12):3576–83.

Kaneko C, Xu C, Liu L, Ning D, Taya M. Electro-deposited vanadium oxide as a counter-electrode for PProDOT-Me2 based electrochromic devices (ECDs). Smart Structures and Materials 2005. Proceedings of SPIE 5759. 2005;5759:518–24.

Acknowledgements

This work received financial support from the National Natural Science Foundation of China (21273207, 21274138, and 21474096) and the “Hundred Talents Program” of CAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing Interests

The authors declare that they have no competing interests.

Authors’ Contributions

FZ carried out the experimental work, characterization, and measurement and wrote the paper. BL assisted in the measurement and revised the manuscript. JZ and CX supervised the whole work. All authors read and approved the final manuscript.

Additional files

Additional file 1:

Output power dependence on the resistance of external load.

Additional file 2:

External impact forces with different Frequencies.

Additional file 3:

I s and V o of the TENG under different frequencies.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, F., Li, B., Zheng, J. et al. Facile Fabrication of Micro-Nano Structured Triboelectric Nanogenerator with High Electric Output. Nanoscale Res Lett 10, 298 (2015). https://doi.org/10.1186/s11671-015-1001-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-015-1001-5

Keywords

- Triboelectric nanogenerator

- Electrospinning

- Polyformaldehyde

- Polytetrafluoroethylene

- Electrochromic device