Abstract

The depth distribution of strain and composition in graded Al x Ga1 − x N films and nanowires (NWs) are studied theoretically using the kinematical theory of X-ray diffraction. By calculating \( \left(20\overline{2}5\right) \) reciprocal space maps (RSMs), we demonstrate significant differences in the intensity distributions from graded Al x Ga1 − x N films and NWs. We attribute these differences to relaxation of the substrate-induced strain on the NWs free side walls. Finally, we demonstrate that the developed X-ray reciprocal space map model allows for reliable depth profiles of strain and Al composition determination in both Al x Ga1 − x N films and NWs.

Similar content being viewed by others

Background

The demonstration of p-type doping through the so-called polarization doping technique for Al x Ga1 − x N alloys is finding more and more practical applications in modern optoelectronic devices. Using compositionally graded Al x Ga1 − x N films, polarization-induced p-n junctions and light emitting diodes (LEDs) have been successfully fabricated [1–3]. This fundamentally new type of p-n junction allowing deep ultraviolet LEDs was shown for graded Al x Ga1 − x N catalyst-free nanowires (NWs) without the use of impurity doping [4, 5]. Such doping enhancement occurs from grading the composition of Al x Ga1 − x N alloys along the c-axis and thus grading the magnitude of the intrinsic polarization in the wurtzite crystal structure. This effectively forms an uncompensated space charge field which is neutralized by free charges of the opposite sign. These free charges become the free electrons and holes which make up a device structure.

The depth profile of the aluminum content is therefore the key factor in controlling the properties of graded Al x Ga1 − x N alloys. However, even for the same Al depth profiles, there is a significant difference between the properties of graded planar films and NWs. The different in- and out-of-plane strain profiles resulting from the free surface of the NWs lead to a difference in (i) the polarization-induced doping carrier densities through differences in the piezoelectric component of the polarization and (ii) the strain-related defect density. Moreover, the large ratio of surface to bulk states can enhance the polarization doping efficiency for graded NWs. In addition, it should be noted that there is also a difference between the strain profiles of catalyst-free and top-down fabricated NWs obtained by dry etching if dislocations form as a result of plastic strain relaxation in the pre-etched material. Therefore, tuning the properties of graded Al x Ga1 − x N films and NWs requires rapid and reliable techniques to determine chemical composition and strain depth profiles.

High resolution X-ray diffraction (HRXRD) is a nondestructive technique that permits rapid determination of the chemical composition, strain state, and thickness of epitaxial films. An X-ray method for measuring the composition and relaxation depth profiles in In x Ga1 − x As/GaAs and GaAs1 − x P x /GaAs graded epitaxial films has been demonstrated in [6]. In [7], the kinematical theory of X-ray diffraction is applied for strain and composition depth profile determination in pseudomorphically grown graded Al x Ga1 − x N/GaN epitaxial films by the simulation of the ω/2θ X-ray diffraction profiles. In this study, we extend the HRXRD method to the case of graded Al x Ga1 − x N NWs through the calculation of asymmetrical reciprocal space maps (RSMs). Particular attention is paid to the in-plane lattice parameter relaxation in Al x Ga1 − x N NWs due to the free sidewalls and how this compares with continuous coherently grown Al x Ga1 − x N films.

Methods

For compositionally graded Al x Ga1 − x N films and NWs, both strain and Al distributions affect the alloy’s lattice parameters and complicate the determination of composition and strain profiles. Moreover, the strain relaxation process in graded Al x Ga1 − x N films differs from that in NWs, which requires a different approach.

In the case of graded Al x Ga1 − x N films, an approach for the determination of the depth profiles of the biaxial strain and the Al composition was proposed in [6]. It requires the measurement of at least two X-ray reflections to give the in-plane lattice parameter (a F ), which allows the out-of-plane, ε ⊥(t), and in-plane, ε ∥(t), strain distribution for an Al composition profile of coherently grown graded Al x Ga1 − x N film (F) to be determined:

where c F (t) is the strained, out-of-plane lattice parameter and c 0(t) and a 0(t) are respectively the fully relaxed out-of-plane and in-plane lattice parameters of the Al x Ga1 − x N film at depth t.

For the case of biaxial strain, the ratio between the ε ⊥(t) and ε ∥(t) for wurtzite crystals is given by

where C 13(t) and C 33(t) are the elastic constants of the fully relaxed Al x Ga1 − x N film at depth t. The relaxed lattice parameters and the elastic constants of the graded Al x Ga1 − x N structure are assumed to vary linearly with the composition, x Al (Vegard’s law).

The substitution of Eqs. (1) and (2) in (3) results in the depth profile of the lattice parameter c F (t) of a coherently grown graded Al x Ga1 − x N film:

Altogether, according to Eq. (4), after measurements of the in-plane lattice parameter (a F = const) of coherently grown graded Al x Ga1 − x N film, the depth distribution of the biaxial strain can be evaluated given an Al composition depth profile. And, as mentioned above, the fitting of an experimental symmetrical or asymmetrical RSM will allow for the separation of the strain and Al composition profiles. This approach is valid both, for coherent films fully strained to the substrate (a F = a S , where a S is the substrate in-plane lattice parameter), i.e., pseudomorphic growth, and also for the case of partially relaxed films (a F ≠ a S ). It should be noted, that depending on the depth profile of the Al composition and the relaxation degree of the graded Al x Ga1 − x N film, the coherent growth on a GaN substrate results in a tensile and/or compressive strain, as demonstrated in Fig. 1.

The depth profile of the Al composition for 300 nm thick graded Al x Ga1 − x N film linearly increasing from x Al = 0 % to x Al = 20 % at the center of the film then linearly decreasing back to x Al = 0 % is shown in Fig. 1a. For this Al distribution the in-plane strain, ε ||(t), profiles are shown in Fig. 1b, calculated according to the Eq. (2) for fully strained and partially relaxed films. Here, we see that pseudomorphic growth of graded Al x Ga1 − x N on [0001] oriented GaN results in tensile in-plane strain along the entire film thickness. In contrast, the relaxation of a coherent graded Al x Ga1 − x N film can result in both tensile and compressive in-plane strains depending on the film’s relaxation degree and the Al composition profile.

It is well understood that misfit strain energy buildup during growth of the heteroepitaxial films and plastic relaxation via misfit dislocation generation can occur if the film thickness exceeds the Matthews–Blakeslee critical thickness [8]. In contrast, due to the free side walls of NW structures, the possibility of elastic strain relaxation exists allowing for a much larger misfit to build up with the substrate. However, the varying Al composition in graded Al x Ga1 − x N NWs will result in a large internal strain even if separated from the substrate, i.e., “free” NWs. To calculate this internal strain, we apply the approach described in [9] where the elastic strain of GaN and AlN layers of an GaN/AlN superlattice is calculated considering the minimum elastic energy of one period of the superlattice. Accordingly, we divide the entire Al x Ga1 − x N NW into sublayers with thickness (l). Then, the in-plane lattice parameter which minimizes the elastic energy is approximated as:

where K(t) is given by

with the constants as before for the fully relaxed Al x Ga1 − x N sublayer at depth t. Therefore, the elastic in-plane strain in a graded Al x Ga1 − x N “free” NW is given by

An exponential decay of the substrate induced strain (\( {\varepsilon}_{\left|\right|}^S \)) for GaN NWs on a Si substrate was experimentally demonstrated in [10–13]. In terms of the in-plane strain throughout the NWs, this is given as:

where ε 0 = (a s − ā)/ā is the initial strain at the NW/substrate interface; L = nD is a characteristic relaxation depth for the NW; D is the diameter of the NW; and n is a dimensionless quantity which can be derived through the solution of the elastic problem for simple geometries [13], but for more complicated geometries, is used as a fitting parameter. In Fig. 2, we demonstrate the relationship between ε 0 and the parameter n with data from strain analysis of GaN/Si(111) NWs formed by “top-down,” dry etching (~250 nm in diameter) [10, 11] as well as formed by catalyst-free “bottom-up” growth (~30–55 nm in diameter) [12, 13]. Here, the small ε 0 and the large diameters of the top-down fabricated NWs compared with catalyst-free NWs indicate that some degree of plastic relaxation has occurred during the growth of the thick heteroepitaxial GaN layer. Thus, we can conclude that both the structural perfection as well as the diameter of a NW has a strong influence on the parameter n, which leads to different strain relaxation depths in GaN NWs fabricated with different techniques (see inset in Fig. 2). Since the relaxation depth determination is beyond the scope of this work and a more detailed experimental analysis of n(ε 0) is not available, we will assume n = 1 for all subsequent calculations of \( {\varepsilon}_{\left|\right|}^S(t) \).

Thus, considering \( {\varepsilon}_{\left|\right|}^{\mathrm{free}}(t) \) and \( {\varepsilon}_{\left|\right|}^S(t) \), the total in-plane strain in graded Al x Ga1 − x N NWs is given by

which results in the depth profile of the in-plane lattice parameter, a NW(t) given by

The depth profiles of the out-of-plane lattice parameter, c NW(t), for graded Al x Ga1 − x N NWs, can be calculated by substitution a F = a NW(t) in Eq. (4).

The depth profiles of the in-plane strain for 300-nm thick graded Al x Ga1 − x N NWs (100 nm in diameter) on Si(111) and GaN(0001) substrates are calculated according to Eq. (9) and presented in Fig. 3. The Al composition profile along the NW length is the same as shown in Fig. 1a for the planar film. In comparison with coherent films, the total strain \( {\varepsilon}_{\left|\right|}^{\mathrm{total}}(t) \) in graded Al x Ga1 − x N NWs is dominated mostly by the substrate at the NW’s bottom, whereas the \( {\varepsilon}_{\left|\right|}^{\mathrm{total}}(t) \) at the NW’s top is affected mostly by the Al composition. In general, by comparison of Fig. 1 and Fig. 3, there are strong differences between the strain profiles of graded Al x Ga1 − x N grown as thin films or grown as NWs with the same Al composition profiles. This should result in different reciprocal space X-ray intensity distribution for these objects.

The \( {\varepsilon}_{\left|\right|}^S(t) \) (red solid curve) and \( {\varepsilon}_{\left|\right|}^{\mathrm{total}}(t) \) (blue solid curve) profiles of graded Al x Ga1 − x N NWs on a Si(111) and b GaN(0001) substrates with the brown solid curves indicating the \( {\varepsilon}_{\left|\right|}^{\mathrm{free}}(t) \) profile. The Al composition profile along the NW length is the same as shown in Fig. 1a for the planar film

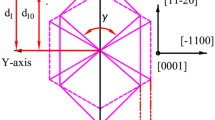

The numerical calculation of RSMs is performed using the kinematical theory of X-ray diffraction, within the limits of which the reciprocal space intensity distribution is given as follows:

where, J 1 is the first order Bessel function and q x and q z are the in-plane and out-of-plane components of the scattering vector; α and D are the out-of-plane orientation angle and lateral size of NW (or crystalline column in case of planar film); f 1(α) and f 2(D) are the Gaussian and log-normal distributions for α and D; c(t) is defined by Eq. (4); \( {\tilde{q}}_x={q}_x\left(\alpha \right) \).

The Gaussian (Eq.(12)) and log-normal (Eq.(13)) distributions of α and D have to be used to correctly describe the broadening of the symmetrical and asymmetrical RSMs for III-nitride [14–17]:

where, σ α is the dispersion parameter in the α distribution; μ and σ D are the location and scale parameters in the D distribution.

Results and Discussion

It is well known that epitaxial films of III-nitrides grow in columnar structures of relatively perfect material bounded by dislocation arrays (the so-called mosaic model) [14–16]. Both the distribution of the out-of-plane orientation angles (α) and of the lateral sizes (D) of crystalline columns cause the broadening of symmetrical and asymmetrical RSMs. Since α and D broaden the RSMs normal to the diffraction vector and along the q x axis, respectively, the two contributions can be separated only in an asymmetrical RSM [3]. Moreover, both the composition and the biaxial strain of graded Al x Ga1 − x N alloys affect the in- and out-of-plane lattice parameters and hence the peak position of asymmetrical RSMs [17]. Therefore, the fitting of an experimental asymmetrical RSM will allow for the separation of strain, composition, and structural parameters in graded Al x Ga1 − x N films and NWs.

First, we apply the proposed model for graded Al x Ga1 − x N films by calculating the intensity distribution of \( \left(20\overline{2}5\right) \) RSMs. For this, we use the f 1(α) distribution for a ranges from −0.5 to 0.5 deg with σ α = 0.05 in Eq. (12) and f 2(D) distribution for D ranges from 30 to 300 nm with σ α = 0.06 in Eq. (13). The c F (t) depth distributions of pseudomorphic (a S = a F = 0.31893 nm) and partially relaxed (a S ≠ a F = 0.318 nm) graded Al x Ga1 − x N films (Fig. 4a) were calculated according to Eq. (4) for the Al composition and in-plane strain profiles shown in Fig. 1. The calculation of \( \left(20\overline{2}5\right) \) RSMs of graded Al x Ga1 − x N films was performed by Eq. (11) for the abovementioned structural and strain/compositional profiles and are shown in Fig. 4b, c.

Calculated \( \left(20\overline{2}5\right) \) RSMs of coherently strained, graded Al x Ga1 − x N films using the depth profiles of the out-of-plane lattice parameters shown in a where the blue line represents pseudomorphic growth and the red line partially relaxed growth. Pseudomorphic and partially relaxed growths on [0001]-oriented GaN substrates are simulated in b and c, respectively. The gray dashed lines indicate the position of pseudomorphic and fully relaxed growth

As can be seen from Fig. 4b, c, coherent growth of both pseudomorphic and partially relaxed compositionally graded films results in continuous intensity distributions along the q z axis of the \( \left(20\overline{2}5\right) \) RSMs with fixed q x positions indicating the relaxation degree of the film. This allows the in-plane lattice parameter of a whole graded Al x Ga1 − x N film to be determined from an experimental asymmetrical RSM; therefore, only the Al composition and strain profile have to be specified for the \( \left(20\overline{2}5\right) \) RSM fitting.

Next, again using Eq. (11), we calculate the \( \left(20\overline{2}5\right) \) RSMs of graded Al x Ga1 − x N NWs using the same f 1(α) distribution as for graded Al x Ga1 − x N films, but now use a constant f 2(D) = 100 nm, to represent the NWs. For this calculation we need the a NW(t) and c NW(t) depth profiles, which we calculate according to Eq. (10) and Eq. (4) for the Al composition and in-plane strain profiles shown in Fig. 1a and Fig. 3, respectively. The resulting lattice constant distributions are shown in Fig. 5a for the cases of graded Al x Ga1 − x N NWs on Si(111), GaN(0001), and for “free” NWs.

a The depth evolution of the out-of-plane lattice parameter, c NW(t), and the in-plane lattice parameter, a NW(t), (inset) of the graded Al x Ga1 − x N NWs grown “free standing” (brown), on GaN(0001) (blue), and on Si(111) (red). Calculated \( \left(20\overline{2}5\right) \) RSMs of graded Al x Ga1 − x N NWs are shown in b for “free” growth, c for growth on GaN(0001), and in d for growth on Si(111). The dashed gray lines indicate the position of pseudomorphic (with respect to GaN) and fully relaxed Al x Ga1 − x N alloy for \( \left(20\overline{2}5\right) \) reflection

In Fig. 5, we see the evolution of the intensity distributions of \( \left(20\overline{2}5\right) \) RSMs of graded Al x Ga1 − x N NWs as the substrate induced strain is reduced from growth on Si(111) to growth on GaN(0001) to growth of “free” NWs. As in the case of the coherently strained graded Al x Ga1 − x N films, the constant in-plane lattice parameter for “free” NWs (\( {\varepsilon}_{\left|\right|}^S(t)=0 \) in Eq. (9)) gives rise to a typical intensity distribution along the q z axis of the \( \left(20\overline{2}5\right) \) RSM (Fig. 5b). In contrast, the exponential decay of the substrate induced strain, \( {\varepsilon}_{\left|\right|}^S(t) \), from the NW’s bottom to the top (Fig. 3) results in the exponential in-plane lattice parameter relaxation (Fig. 5a, inset) and to a slope in the \( \left(20\overline{2}5\right) \) RSM as shown in Fig. 5c and Fig. 5d for graded Al x Ga1 − x N NWs on GaN (with a s = 0.31893 nm) and Si (a s = 0.32 nm) substrates, respectively. Also, there are significant differences in RSMs for graded Al x Ga1 − x N NWs grown on GaN and Si substrates. As the difference in in-plane lattice constants from the base of the NW to the top becomes larger, we start to see a bifurcation of the lower lobes in the RSM as seen for the NW growth on the Si substrate in Fig. 5d. This is a unique feature of vertically aligned NWs, which exhibit large elastic relaxation along their length. This model is therefore not only very versatile in that it can be applied to NWs growing on different substrates, it is very powerful in that it can give definite lattice information along the entire length of the NW.

Finally, we want to pay attention to the maxima in the X-ray intensity distribution from both graded Al x Ga1 − x N films and NWs. These pronounced peaks, while very similar to in appearance, cannot be attributed to the Kiessig fringes alone, but rather to a coherent superposition of scattering vectors with appropriate lengths, as a result of the depth distribution of the concentration, x Al(t), in the graded Al x Ga1 − x N structure. Thereby, this shows the very high sensitivity of the RSMs to x Al(t) changes. Thus, the developed HRXRD method can be applied as a fast, non-destructive method for controlling the depth distribution of the Al with very high precision.

Conclusions

In conclusion, we present a method for the efficient strain and composition depth profile determination of graded Al x Ga1 − x N films and NWs by fitting asymmetrical \( \left(20\overline{2}5\right) \) RSMs. The peculiarities of strain relaxation are demonstrated for 300-nm thick coherent graded Al x Ga1 − x N films in comparison with partially relaxed graded Al x Ga1 − x N NWs. An internal strain due to Al composition variation and a substrate induced strain which exponentially relaxes from the NW’s bottom to the top were considered. We show that asymmetrical RSMs contain enough information for reliable strain and composition determination.

References

Simon J, Protasenko V, Lian C et al. (2010) Polarization-induced hole doping in wide-band-gap uniaxial semiconductor heterostructures. Science 327:60–64. doi:10.1126/science.1183226

Li S, Ware ME, Kunets VP et al. (2011) Polarization induced doping in graded AlGaN films. Phys status solidi 8:2182–2184. doi:10.1002/pssc.201001072

Kuchuk AV, Lytvyn PM, Li C et al. (2015) Nanoscale electrostructural characterization of compositionally graded Al x Ga1– x N heterostructures on GaN/sapphire (0001) substrate. ACS Appl Mater Interfaces 7:23320–23327. doi:10.1021/acsami.5b07924

Carnevale SD, Kent TF, Phillips PJ et al. (2012) Polarization-induced pn diodes in wide-band-gap nanowires with ultraviolet electroluminescence. Nano Lett 12:915–20. doi:10.1021/nl203982p

Carnevale SD, Kent TF, Phillips PJ et al. (2013) Mixed polarity in polarization-induced p–n junction nanowire light-emitting diodes. Nano Lett 13:3029–3025. doi:10.1021/nl400200g

Benediktovitch A (2011) Concentration and relaxation depth profiles of InxGa1−xAs/GaAs and GaAs1−xPx/GaAs graded epitaxial films studied by x-ray diffraction. 035302:1–7. doi: 10.1103/PhysRevB.84.035302

Kuchuk AV, Stanchu HV, Li C et al. (2014) Measuring the depth profiles of strain/composition in AlGaN-graded layer by high-resolution x-ray diffraction. J Appl Phys 116:224302. doi:10.1063/1.4904083

Tyagi A, Wu F, Young EC et al. (2009) Partial strain relaxation via misfit dislocation generation at heterointerfaces in (Al, In)GaN epitaxial layers grown on semipolar (1122) GaN free standing substrates. Appl Phys Lett 95:251905. doi:10.1063/1.3275717

Kandaswamy PK, Guillot F, Bellet-Amalric E et al. (2008) GaN/AlN short-period superlattices for intersubband optoelectronics: s systematic study of their epitaxial growth, design, and performance. J Appl Phys 104:093501. doi:10.1063/1.3003507

Tseng WJ, Gonzalez M, Dillemans L et al. (2012) Strain relaxation in GaN nanopillars. Appl Phys Lett 101:1–5. doi:10.1063/1.4772481

Hugues M, Shields PA, Sacconi F et al (2013) Strain evolution in GaN nanowires: from free-surface objects to coalesced templates. J Appl Phys 114:084307. doi:10.1063/1.4818962

Stanchu H, Kladko V, Kuchuk AV, et al. (2015) High-resolution X-ray diffraction analysis of strain distribution in GaN nanowires on Si(111) substrate. Nanoscale Res Lett 10:0–4. doi: 10.1186/s11671-015-0766-x

Kaganer VM, Jenichen B, Brandt O et al. (2012) Inhomogeneous strain in GaN nanowires determined from x-ray diffraction peak profiles. Phys Rev B - Condens Matter Mater Phys 86:1–7. doi:10.1103/PhysRevB.86.115325

Zielińska-Rohozińska E, Regulska M, Harutyunyan VSS et al. (2002) High resolution X-ray diffraction defect structure characterization in Si-doped and undoped GaN films. Mater Sci Eng B 91–92:441–444. doi:10.1016/S0921-5107(01)00996-5

Metzger T, Höpler R, Born E et al. (1998) Defect structure of epitaxial GaN films determined by transmission electron microscopy and triple-axis X-ray diffractometry. Philos Mag A 77:1013–1025. doi:10.1080/01418619808221225

Kladko V, Kuchuk A, Lytvyn P et al. (2012) Substrate effects on the strain relaxation in GaN/AlN short-period superlattices. Nanoscale Res Lett 7:289. doi:10.1186/1556-276X-7-289

Wallis DJ, Zhu D, Oehler F et al. (2013) Measuring the composition of AlGaN layers in GaN based structures grown on 150 mm Si substrates using (2 0 5) reciprocal space maps. Semicond Sci Technol 28:094006. doi:10.1088/0268-1242/28/9/094006

Acknowledgements

This study was supported by the National Science Foundation Engineering Research Center for Power Optimization of Electro Thermal Systems (POETS) with cooperative agreement EEC-1449548 and the National Academy of Sciences of Ukraine within the framework of the fundamental researches program, project no. 24/15-H.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

HS and AK proposed and realized the idea and drafted the manuscript. VK, MW, YM, ZZ, AB, and GS reviewed the results and contributed to the manuscript. All authors read and approved the final manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Stanchu, H.V., Kuchuk, A.V., Kladko, V.P. et al. X-ray Reciprocal Space Mapping of Graded Al x Ga1 − x N Films and Nanowires. Nanoscale Res Lett 11, 81 (2016). https://doi.org/10.1186/s11671-016-1299-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s11671-016-1299-7